Efficient polishing method for light control glass

A high-efficiency technology of dimming glass, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of reducing polishing efficiency, increasing polishing time-consuming, and low polishing efficiency. Improve the efficiency of annealing, improve efficiency, increase the effect of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

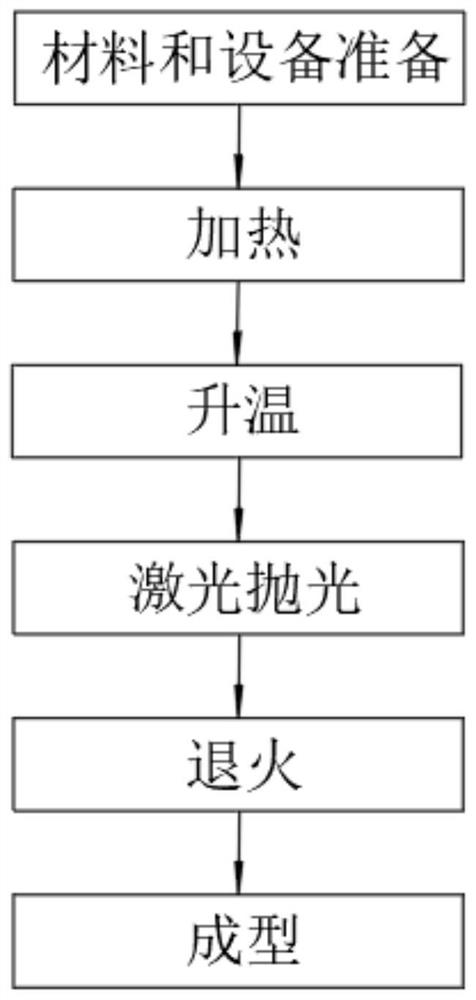

[0034] A method for polishing high-efficiency dimming glass, comprising the steps of:

[0035] Step 1: Preparation of materials and equipment: the material is dimming glass; the equipment includes: tunnel furnace, continuous wave (CW) laser located in the tunnel furnace, the model of continuous wave (CW) laser is CW-DPSSL, and controller, The controller is equipped with PLC;

[0036] Step 2: Heating: Place the dimming glass to be polished on the conveyor belt of the tunnel furnace, and drive the dimming glass to move into the heating zone of the tunnel furnace through the conveyor belt for heating. The heating zone of the tunnel furnace can be heated by infrared rays or Adopt ceramic electric heating;

[0037] Step 3: Heating up: the tunnel furnace raises the temperature of the dimming glass to the preset temperature. The preheating temperature needs to be set according to the material, size and shape of the dimming glass workpiece, and the temperature is 200°C;

[0038] Ste...

Embodiment 2

[0045] A method for polishing high-efficiency dimming glass, comprising the steps of:

[0046] Step 1: Preparation of materials and equipment: the material is dimming glass; the equipment includes: tunnel furnace, continuous wave (CW) laser located in the tunnel furnace, the model of continuous wave (CW) laser is CW-DPSSL, and controller, The controller is equipped with PLC;

[0047] Step 2: Heating: Place the dimming glass to be polished on the conveyor belt of the tunnel furnace, and drive the dimming glass to move into the heating zone of the tunnel furnace through the conveyor belt for heating. The heating zone of the tunnel furnace can be heated by infrared rays or Adopt ceramic electric heating;

[0048] Step 3: Heating up: The tunnel furnace raises the temperature of the dimming glass to the preset temperature. The preheating temperature needs to be set according to the material, size and shape of the dimming glass workpiece, and the temperature range is 600°C;

[004...

Embodiment 3

[0056] A method for polishing high-efficiency dimming glass, comprising the steps of:

[0057] Step 1: Preparation of materials and equipment: the material is dimming glass; the equipment includes: tunnel furnace, continuous wave (CW) laser located in the tunnel furnace, the model of continuous wave (CW) laser is CW-DPSSL, and controller, The controller is equipped with PLC;

[0058] Step 2: Heating: Place the dimming glass to be polished on the conveyor belt of the tunnel furnace, and drive the dimming glass to move into the heating zone of the tunnel furnace through the conveyor belt for heating. The heating zone of the tunnel furnace can be heated by infrared rays or Adopt ceramic electric heating;

[0059] Step 3: Heating up: The tunnel furnace raises the temperature of the dimming glass to the preset temperature. The preheating temperature needs to be set according to the material, size and shape of the dimming glass workpiece, and the temperature range is 1000°C;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com