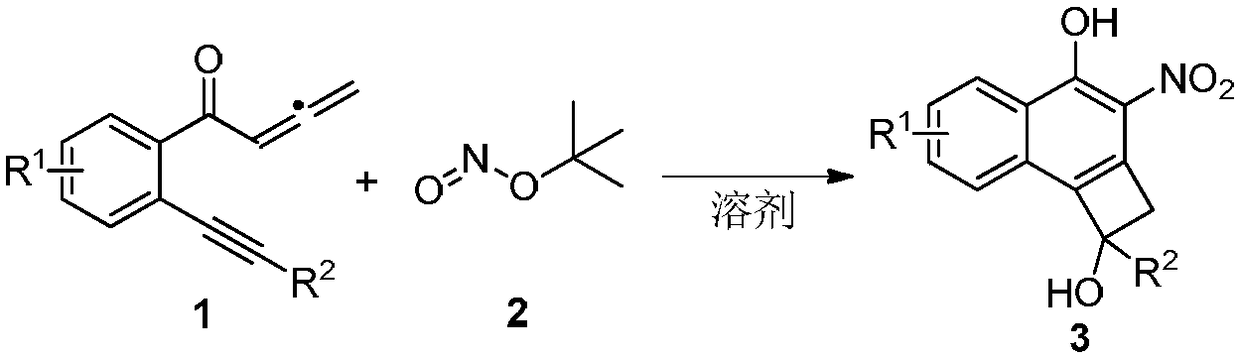

Synthesis method of cyclobutanol nitro-substituted naphthol compound

A synthesis method and compound technology, applied in the preparation of nitro compounds, organic chemistry, etc., can solve the problems of a large number of by-products, low product yield, expensive reagents, etc., and achieve simple operation, high atom economy, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

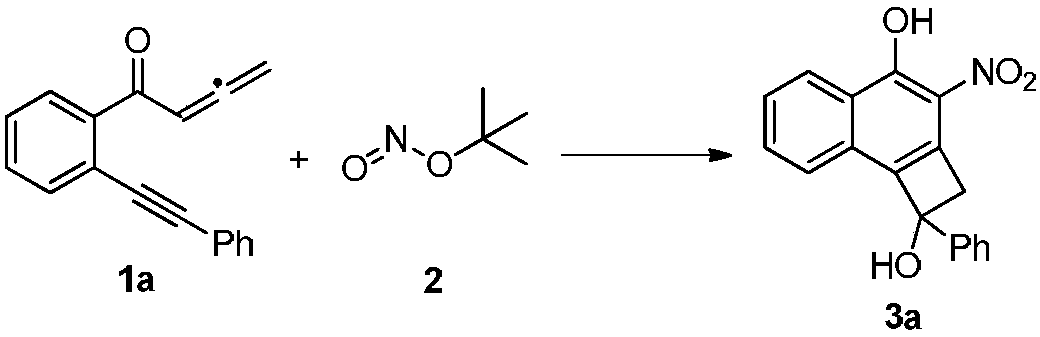

Embodiment 1

[0014]

[0015] 1a (0.5mmol, 122mg), 2 (1.5mmol, 178μL) and acetonitrile (3mL) were sequentially added into a reaction tube, and the reaction was stirred at 50°C for 3h under an air atmosphere. Then the solvent was spin-dried and separated by silica gel column (petroleum ether / ethyl acetate=10 / 1) to obtain orange solid product 3a (77 mg, 50%). The characterization data of this compound are as follows: 1 H NMR (400MHz, CDCl 3 )δ:3.03(m,1H),3.80(d,J=14.8Hz,1H),3.86(d,J=14.4Hz,1H),7.28-7.34(m,3H),7.42-7.45(m,2H ),7.54-7.58(m,1H),7.61-7.68(m,2H),8.54(d,J=8.4Hz,1H),12.13(s,1H). 13 C NMR (100MHz, CDCl 3 )δ: 51.5, 81.1, 122.9, 125.2, 125.3, 125.9, 126.4, 126.7, 127.8, 128.6, 132.0, 132.2, 134.0, 136.2, 142.3, 156.9. HRMS calcd for C 18 h 13 NO 4 :306.0772[M-H] - ,found: 306.0775.

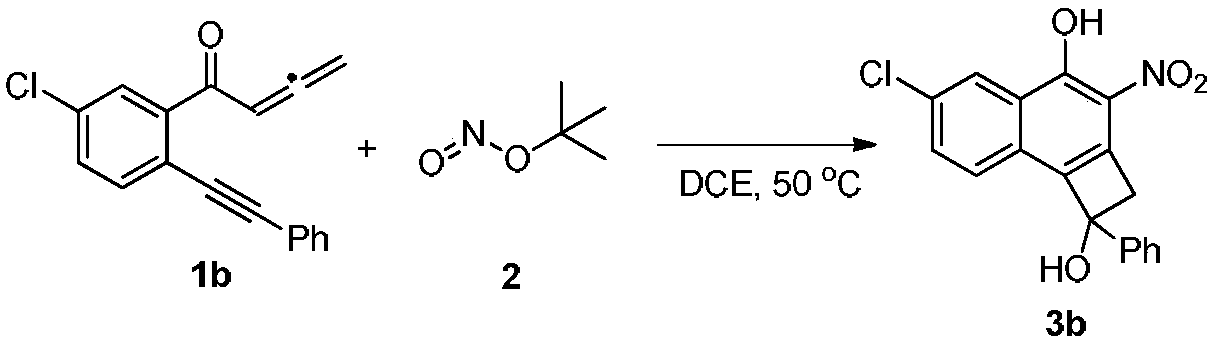

Embodiment 2

[0017] 1a (0.5mmol, 122mg), 2 (1.5mmol, 178μL) and toluene (3mL) were sequentially added into the reaction tube, and the reaction was stirred at 50°C for 3h under air atmosphere. Then the solvent was spin-dried and separated by silica gel column (petroleum ether / ethyl acetate=10 / 1) to obtain the orange solid product 3a (49 mg, 32%).

Embodiment 3

[0019] 1a (0.5mmol, 122mg), 2 (1.5mmol, 178μL) and 1,4-dioxane (3mL) were sequentially added into the reaction tube, and the reaction was stirred at 50°C for 3h under air atmosphere. Then the solvent was spin-dried and separated by silica gel column (petroleum ether / ethyl acetate=10 / 1) to obtain the orange solid product 3a (62 mg, 40%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com