Novel rotary material tray supporting arm

A material tray and rotating shaft technology, which is applied in the direction of furnace types, furnaces, heat treatment equipment, etc., can solve the problems of high cost and short service life, and achieve the effect of less consumables, long service life and rich auxiliary functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific implementation mode 1: This implementation mode is a high-temperature heat treatment rotating tray, using austenitic stainless steel, which has good high-temperature oxidation resistance performance, heat strength performance and processing performance.

[0017] The whole adopts precision casting to form at one time, which reduces the manufacturing cost.

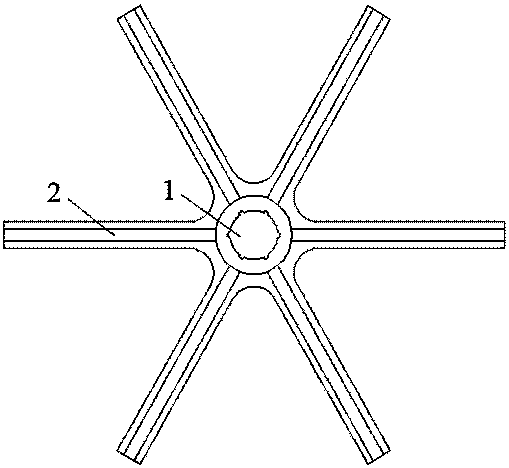

[0018] It includes the core rotating connection structure and 6 spiral arms.

[0019] The tray has six arms in total, and each arm has a uniform keel structure up and down;

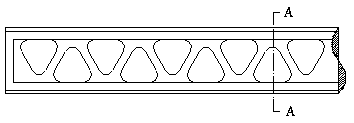

[0020] The two sides of the cantilever are sunken, and the structural section is shown in Figure 4 shown;

[0021] The interior of each swing arm is connected by a stable structure arranged in a triangle, which can bear heavy materials;

[0022] Through the connection of the rotating shaft, the rotation of the tray can make the tray evenly heated;

[0023] On the plane of the tray, various supporting parts (such as pads, gaskets, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com