Micro-arc oxidation method for inner cavity structure

A micro-arc oxidation and inner cavity technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of incapable of oxidation of inner cavity parts, and achieve the effect of low maintenance cost and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

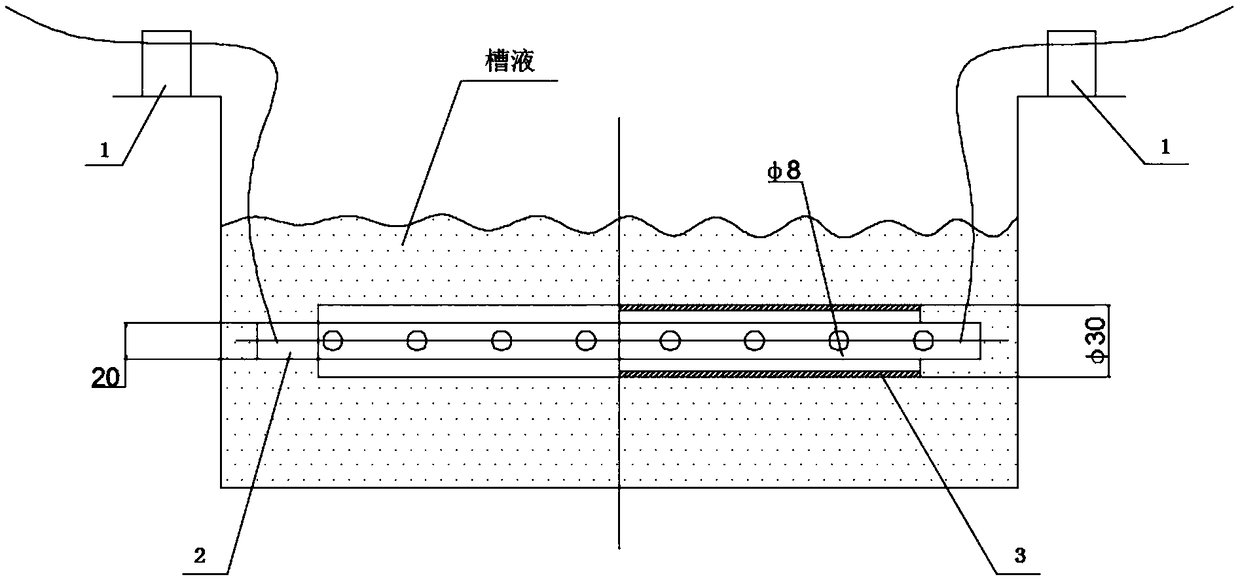

[0026] For φ30mm aluminum alloy component 3, design a built-in cathode and open a φ8mm hole on the cathode to ensure the effective area of the cathode scattering on the electric field of aluminum alloy component 3. Turn on the power terminal 1, set reasonable oxidation parameters, and start the aluminum alloy Oxidation of part 3.

[0027] (1) Prepare electrolyte: add 40g / L sodium hexametaphosphate and WH-3 5g / L into purified water and stir until completely dissolved. Then add an appropriate amount of sodium silicate to adjust the Ph to 7-8.

[0028] (2) Prepare aluminum alloy parts 3 with specifications of φ30mm×500mm, degrease and wash with water.

[0029] (3) Process 600mm×20mm×2mm built-in cathode.

[0030] (4) Put the aluminum alloy part 3 into the oxidation tank, insert the built-in cathode into the inner cavity of the aluminum alloy part 3, control the cathode and the inner wall of the aluminum alloy part to leave a certain gap, and connect the cathode and anode.

[0031] (5) ...

Embodiment 2

[0035] According to the oxidized φ35 aluminum alloy part 3 inner cavity workpiece, a built-in cathode is designed, and a φ8mm hole is opened on the cathode to ensure the effective area of the cathode scattering on the electric field of the aluminum alloy part 3, and the power terminal 1 is connected. Set reasonable oxidation parameters to start the oxidation of the aluminum alloy part 3.

[0036] (1) Prepare electrolyte: add 35g / L sodium hexametaphosphate and WH-3 2g / L into purified water and stir until completely dissolved. Then add an appropriate amount of sodium silicate to adjust the Ph to 7-8.

[0037] (2) Prepare aluminum alloy parts 3 with specifications of φ35mm×500mm, degrease and wash with water.

[0038] (3) Process 600mm×25mm×2mm built-in cathode.

[0039] (4) Put the aluminum alloy part 3 into the oxidation tank, insert the built-in cathode into the inner cavity of the aluminum alloy part 3, control the cathode to leave a certain gap with the inner cavity wall of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com