Buried steel pipeline damage full-tensor geomagnetic detection system and implementation method

A geomagnetic detection, full tensor technology, applied in pipeline systems, material magnetic variables, mechanical equipment, etc., to achieve efficient extraction and reliable identification, high reliability, and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

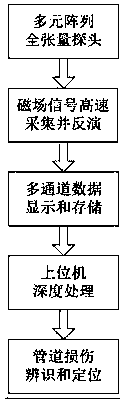

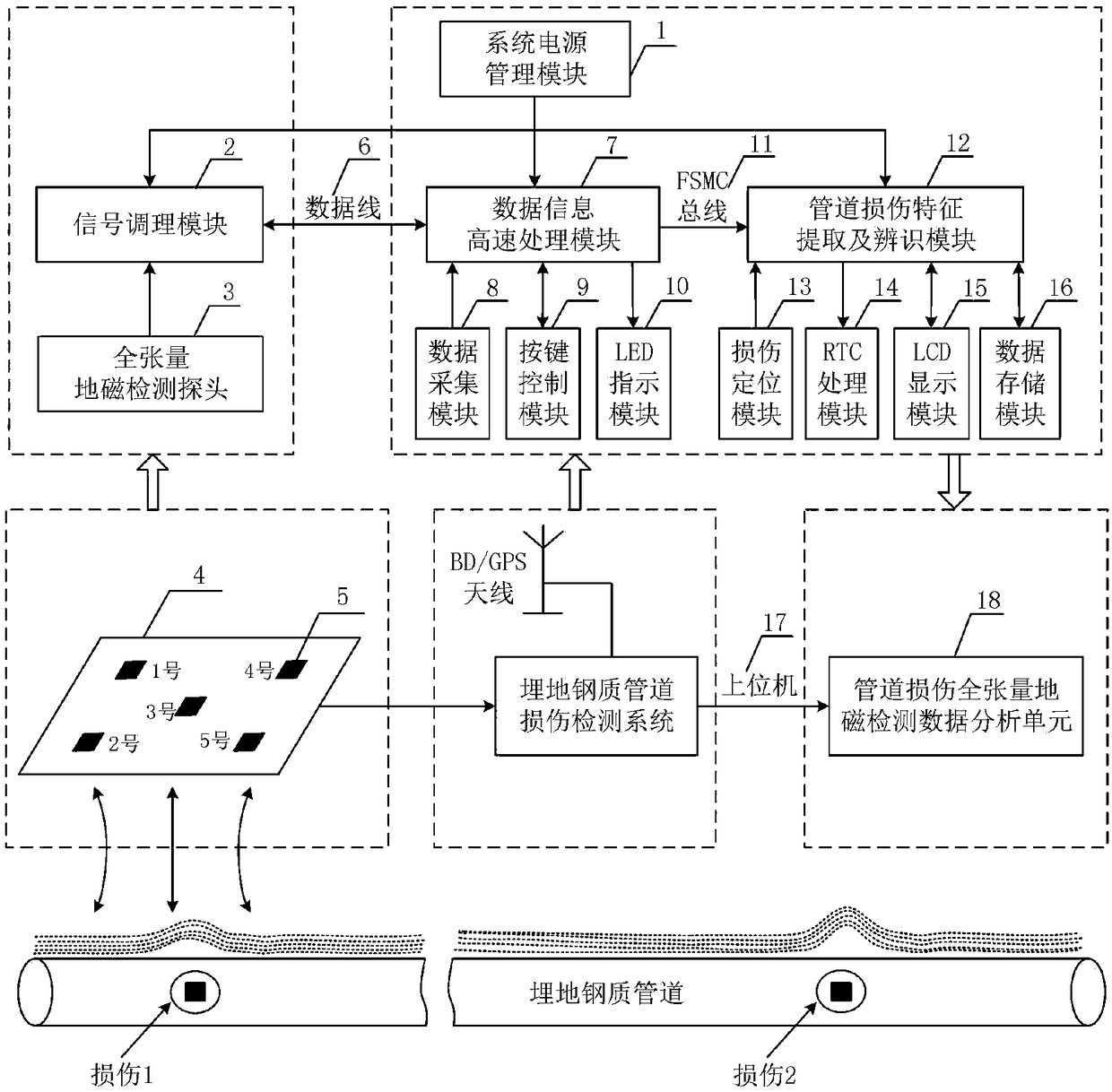

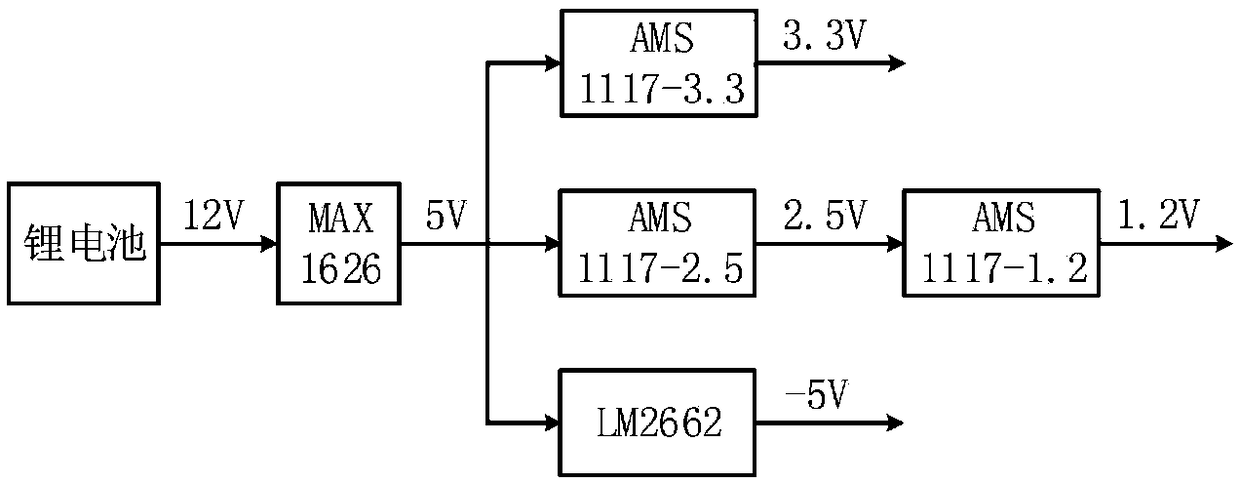

[0042] A buried steel pipeline damage full-tensor geomagnetic detection system and its implementation method according to the present invention are based on the geomagnetic theory and the magnetic gradient full-tensor analysis method, and a multi-sensor array probe is designed, which is controlled by FPGA and ARM dual main control cores Each module cooperates to realize the target magnetic field detection, and then realizes the ground non-excavation diagnosis identification and location of the buried steel pipeline body damage. figure 1 It is a schematic diagram of a full-tensor geomagnetic detection system for buried steel pipeline damage and its implementation method according to the present invention, including: a system power management module (1), a signal conditioning module (2), a full-tensor geomagnetic detection probe (3), and a multi-element array Structure (4), three-axis tunnel magnetoresistive sensor (5), data line (6), data information high-speed processing module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com