Double pulse test circuit and method of flying capacitor three-level DCDC power component

A flying capacitor and power component technology, applied in the pulse test circuit field of flying capacitor three-level DCDC power components, can solve the problem that the double-pulse test method cannot be directly applied to flying capacitor three-level power components, etc. Effectiveness of Reliable and Effective Test Methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

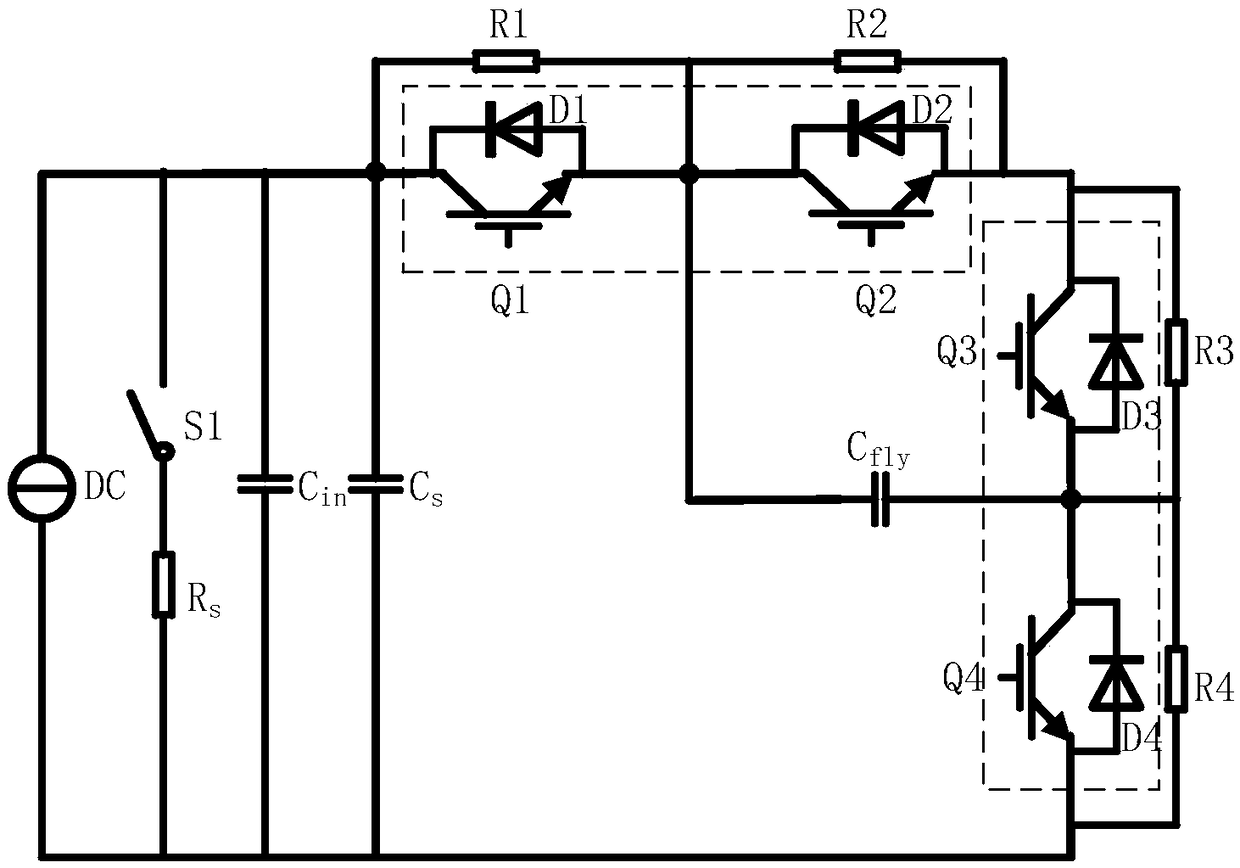

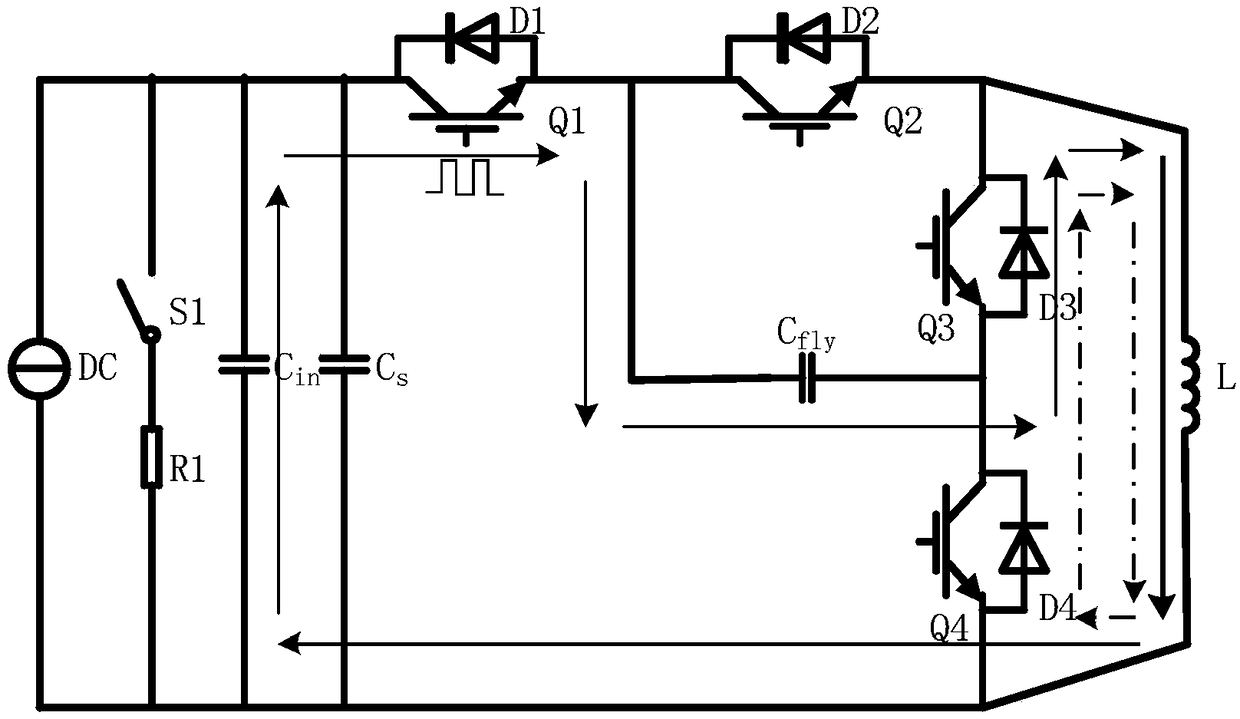

[0053] refer to figure 1 As shown, the double-pulse test circuit of the flying capacitor three-level DC / DC power component of this embodiment includes a three-level power module, an adjustable DC source DC, a discharge branch and a freewheeling inductance L;

[0054] The three-level power module includes the flying capacitor C fly , DC support capacitor C in , Snubber capacitance C s and a switch conversion circuit; the switch conversion circuit includes a first IGBT switch tube Q1, a second IGBT switch tube Q2, a third IGBT switch tube Q3, and a fourth IGBT switch tube Q4 connected in series in the same direction; the emitters of each IGBT and The freewheeling diodes D1-D4 are respectively reversely connected to the collectors; one end of the flying capacitor C is connected between the first IGBT emitter and the second IGBT collector, and the other end is connected between the third IGBT emitter and the fourth IGBT between IGBT collectors;

[0055] The first IGBT, the sec...

Embodiment 2

[0066] Based on the test circuit of Embodiment 1, this embodiment is a test method for a double-pulse test circuit of a flying capacitor three-level DC / DC power component, including:

[0067] Adjust the adjustable DC source DC to charge the support capacitor to the rated voltage V DC , and then charge the flying capacitor to V through the equalizing resistors R1-R4 DC / 2;

[0068] Disconnect the adjustable DC source DC to stop charging;

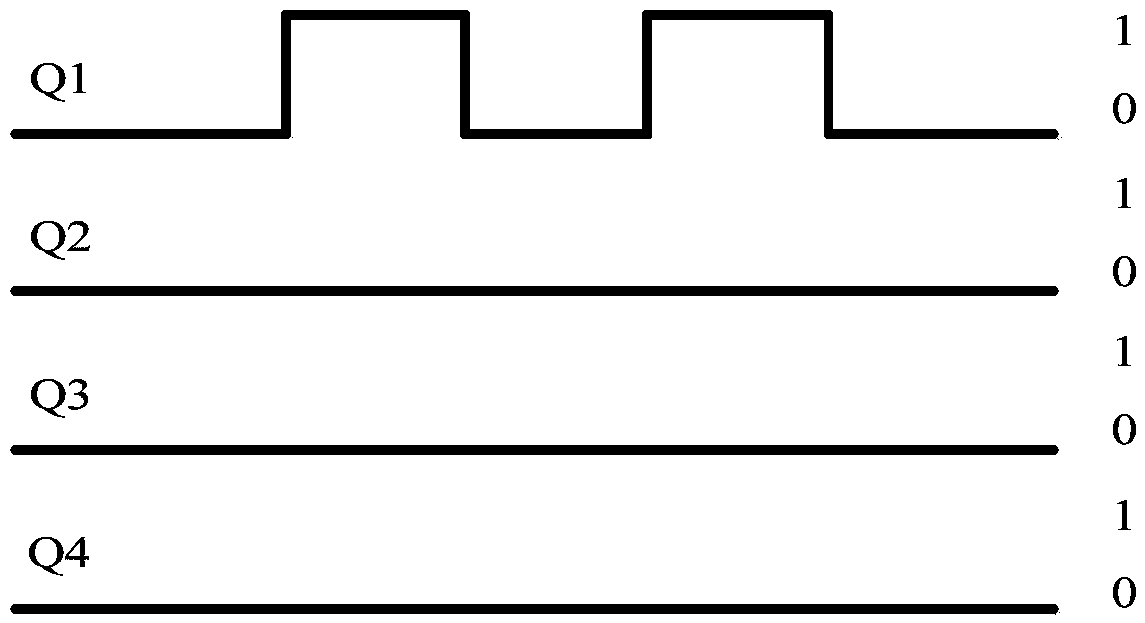

[0069] Determine the switching transformation form of the three-level power module and the corresponding test object IGBT switch tube;

[0070] According to the switch conversion form, control the IGBT switch tubes other than the test object IGBT switch tube to turn off or normally open;

[0071] Apply double pulses to the IGBT switch tube of the test object;

[0072] Measure the gate-emitter voltage V of the IGBT switch tube of the test object during the application of the double pulse GE , collector-emitter voltage V CE , and the reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com