A kind of processing method of multi-layer circuit board containing PTFE

A multi-layer circuit board and processing technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems that affect the quality of signal transmission and cannot be removed during processing, so as to improve processing efficiency and avoid interference of signal transmission , Avoid the abnormal effect of product combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

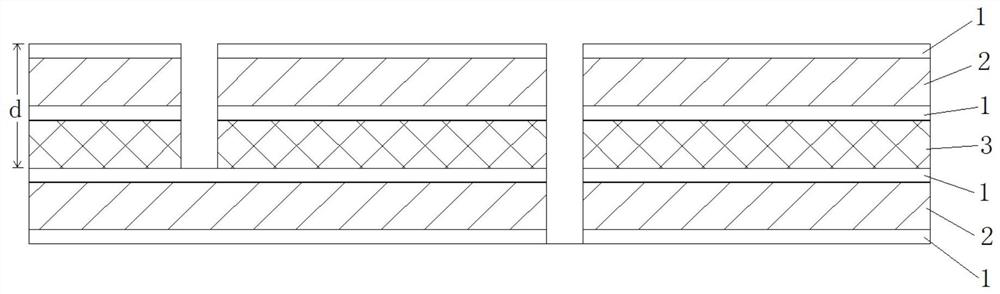

[0025] Such as figure 1 As shown, the multilayer circuit board in which the PTFE board layer and the glass cloth board layer are mixed and pressed, and the middle core board is a PTFE board layer, wherein the PTFE board layer includes PTFE, glass cloth and ceramics, and its processing method includes the following steps:

[0026] ① Cutting: Cut the copper clad laminate containing PTFE and the copper clad laminate made of glass cloth according to the design size;

[0027] ②Pattern transfer between the inner circuit board and the outer circuit board: Paste the dry film on the surface of the copper clad board, then use the inner hole of the board for alignment, expose the dry film, develop it, and etch the inner circuit board and the outer circuit board out the required graphics;

[0028] ③Lamination: Press and paste the inner circuit board and the outer circuit board to make a multi-layer circuit board, in which the core board is a PTFE board.

[0029] ④ Drilling: Drill holes ...

Embodiment 2

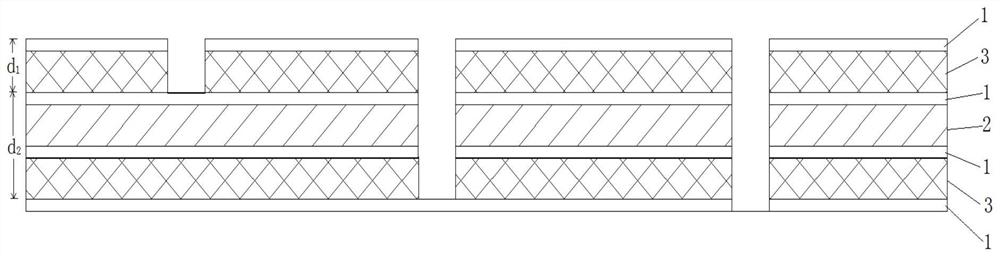

[0032] Such as figure 2 Shown, the multilayer circuit board that PTFE board layer and glass cloth board layer are mixed press, and intermediate core board is glass cloth board layer, and wherein, PTFE board layer comprises PTFE and glass cloth, and its preparation method comprises the following steps:

[0033] ① Cutting: Cut the copper clad laminate according to the design size, and the components of the two copper clad laminates include PTFE and glass cloth;

[0034] ②Pattern transfer between the inner circuit board and the outer circuit board: Paste the dry film on the surface of the copper clad board, then use the inner hole of the board for alignment, expose the dry film, develop it, and etch the inner circuit board and the outer circuit board out the required graphics;

[0035] ③Lamination: Press and paste the inner circuit board and the outer circuit board to make a multi-layer circuit board.

[0036] ④ Drilling: Drill holes on the multilayer circuit board made in ste...

Embodiment 3

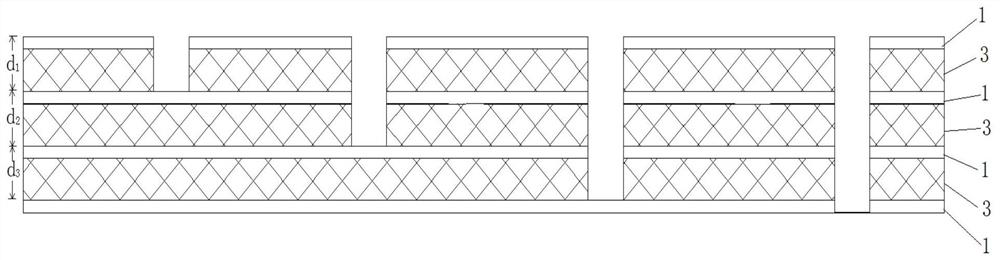

[0039] Such as image 3 Shown, the multilayer circuit board that a plurality of PTFE plate layers are mixed pressure, its preparation method comprises the following steps:

[0040] ① Cutting: Cut the copper clad laminate according to the design size, and each copper clad laminate contains PTFE and glass cloth;

[0041] ②Pattern transfer between the inner circuit board and the outer circuit board: Paste the dry film on the surface of the copper clad board, then use the inner hole of the board for alignment, expose the dry film, develop it, and etch the inner circuit board and the outer circuit board out the required graphics;

[0042] ③Lamination: Press and paste the inner circuit board and the outer circuit board to make a mixed-pressure multi-layer circuit board.

[0043] ④ Drilling: Drill holes in the multi-layer circuit board made in step ③. The drilling method adopts segmental drilling. First drill through the PTFE layer, and then drill through the remaining materials. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com