A kind of water-based epoxy primer for pre-coated coils and preparation method thereof

A water-based epoxy and water-based epoxy emulsion technology, applied in the paint field, can solve problems such as poor adhesion and salt spray resistance, difficulty in water-based, and greater impact on physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a water-based epoxy primer for precoated coils described in the above technical solution, comprising the following steps:

[0041] Mix water-based epoxy emulsion, pigments and fillers, amino resin, substrate wetting agent, leveling agent, water-based salt spray resistance additive and water to obtain a water-based epoxy primer for pre-coated coils.

[0042] In the preparation method provided by the present invention, the water-based epoxy primer for pre-coated coils can be obtained by directly mixing the raw materials evenly according to the proportion. Wherein, the raw materials include water-based epoxy emulsion, pigments and fillers, amino resins, substrate wetting agents, leveling agents, water-based salt spray resistance additives and water, preferably also include dispersants and / or antirust pigments, the present invention The specific selection and dosage of each raw material have been introduced above, a...

Embodiment 1

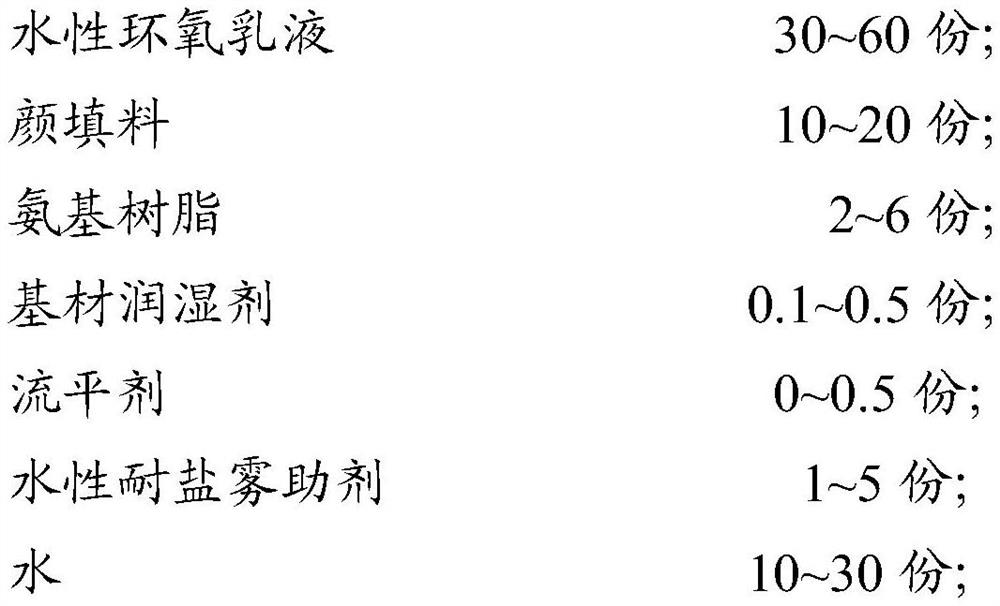

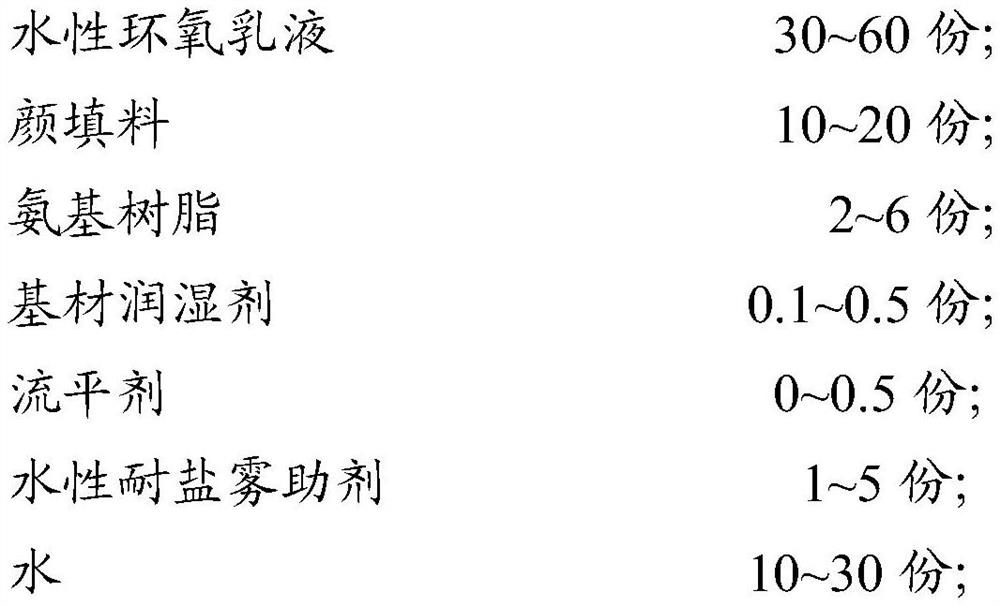

[0048] 1) Raw material formula

[0049]

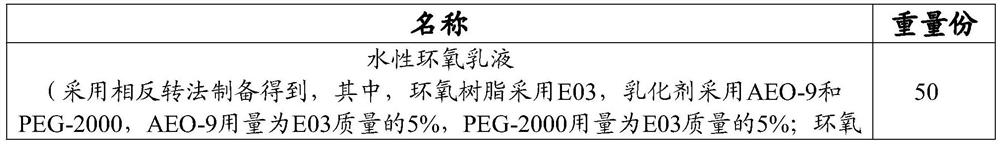

[0050]

[0051] 2) Prepare water-based epoxy primer according to the above-mentioned raw material formula

[0052] Step 1: Mix the water-based epoxy emulsion with dispersant, substrate wetting agent, leveling agent, water-based salt spray resistance additive and water, and stir evenly with a disperser to obtain a mixture;

[0053] Step 2: Add pigments, fillers, anti-rust pigments and amino resins to the above mixture, and use a disperser to disperse evenly, then use a basket sand mill to grind to a fineness of <20μm, and control the grinding temperature to <50°C.

Embodiment 2

[0055] 1) Raw material formula

[0056]

[0057]

[0058] 2) Prepare epoxy primer according to the above raw material formula

[0059] Step 1: Mix the water-based epoxy emulsion with dispersant, substrate wetting agent, leveling agent, water-based salt spray resistance additive and water, and stir evenly with a disperser to obtain a mixture;

[0060] Step 2: Add pigments, fillers, anti-rust pigments and amino resins to the above mixture, and use a disperser to disperse evenly, then use a basket sand mill to grind to a fineness of <20μm, and control the grinding temperature to <50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com