Blowing system for viscose yarn

A technology of cleaning and viscose, applied in textile and papermaking, fiber processing, continuous processing, etc., can solve the problems of reducing the production efficiency of viscose yarn, increasing the labor intensity of workers, etc., to improve fluency, stability, and saving. Manual, the effect of improving the transport rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

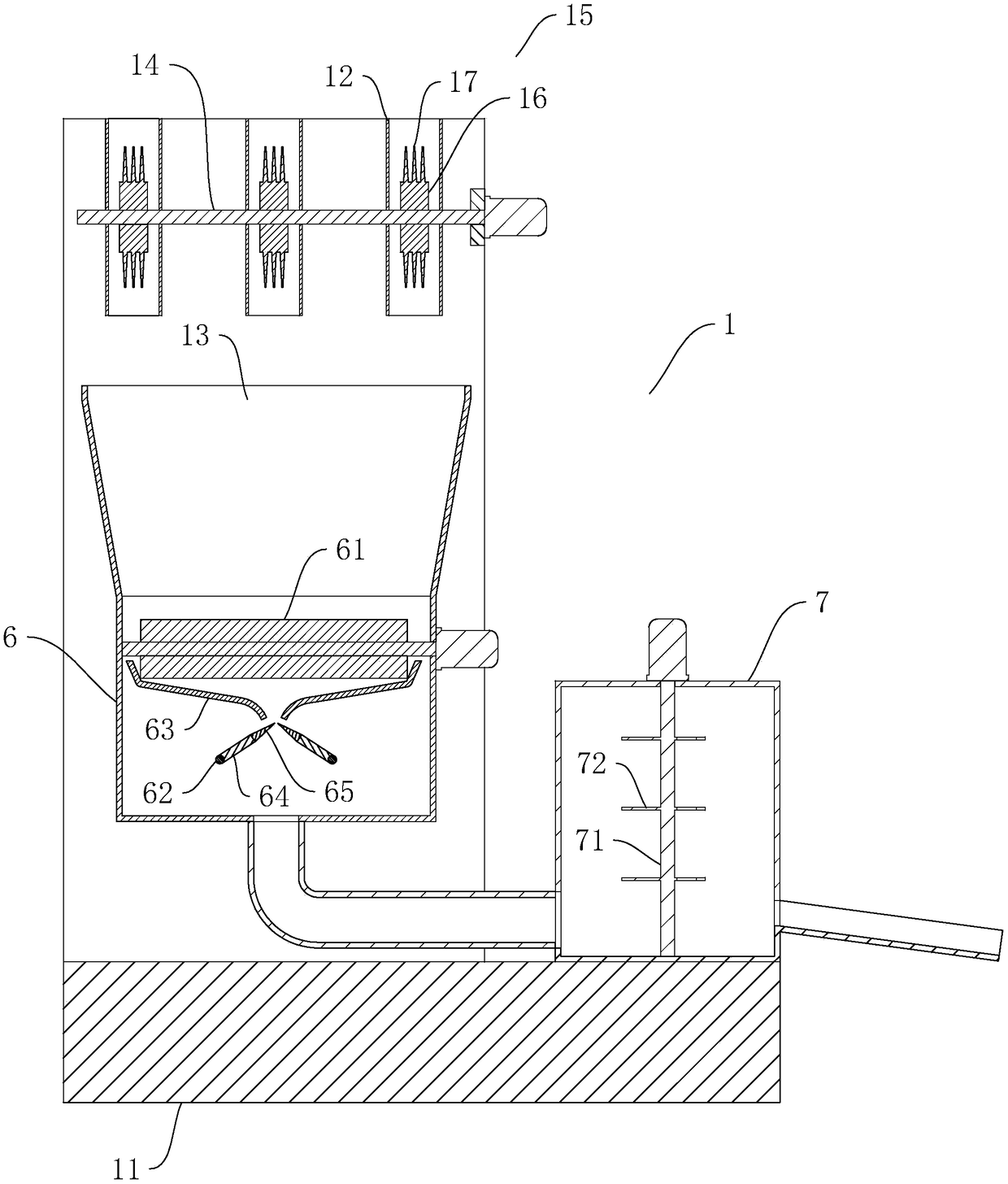

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

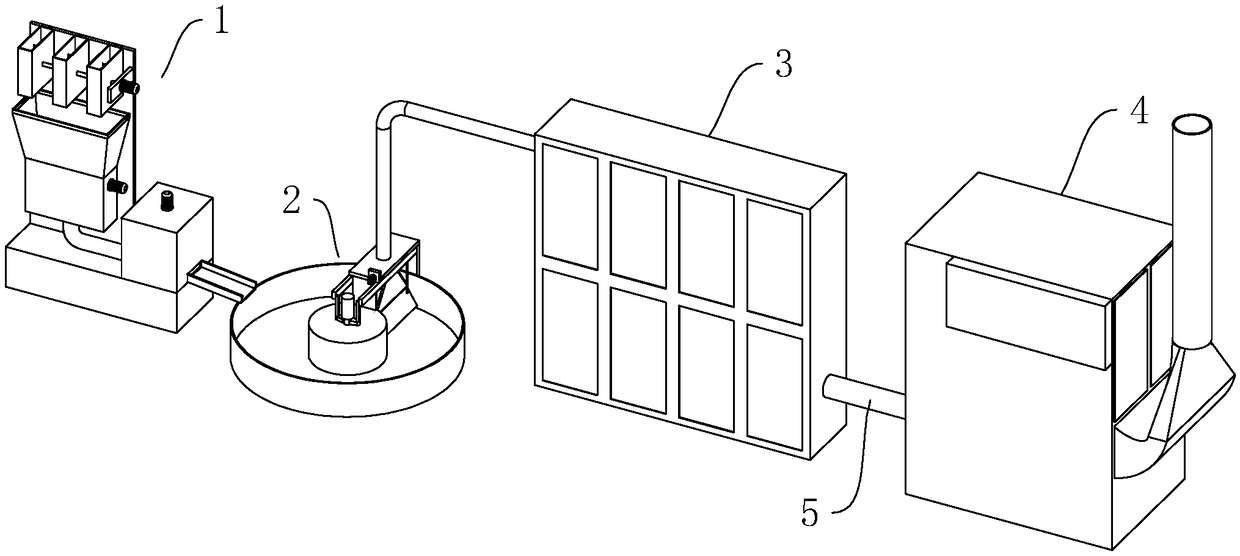

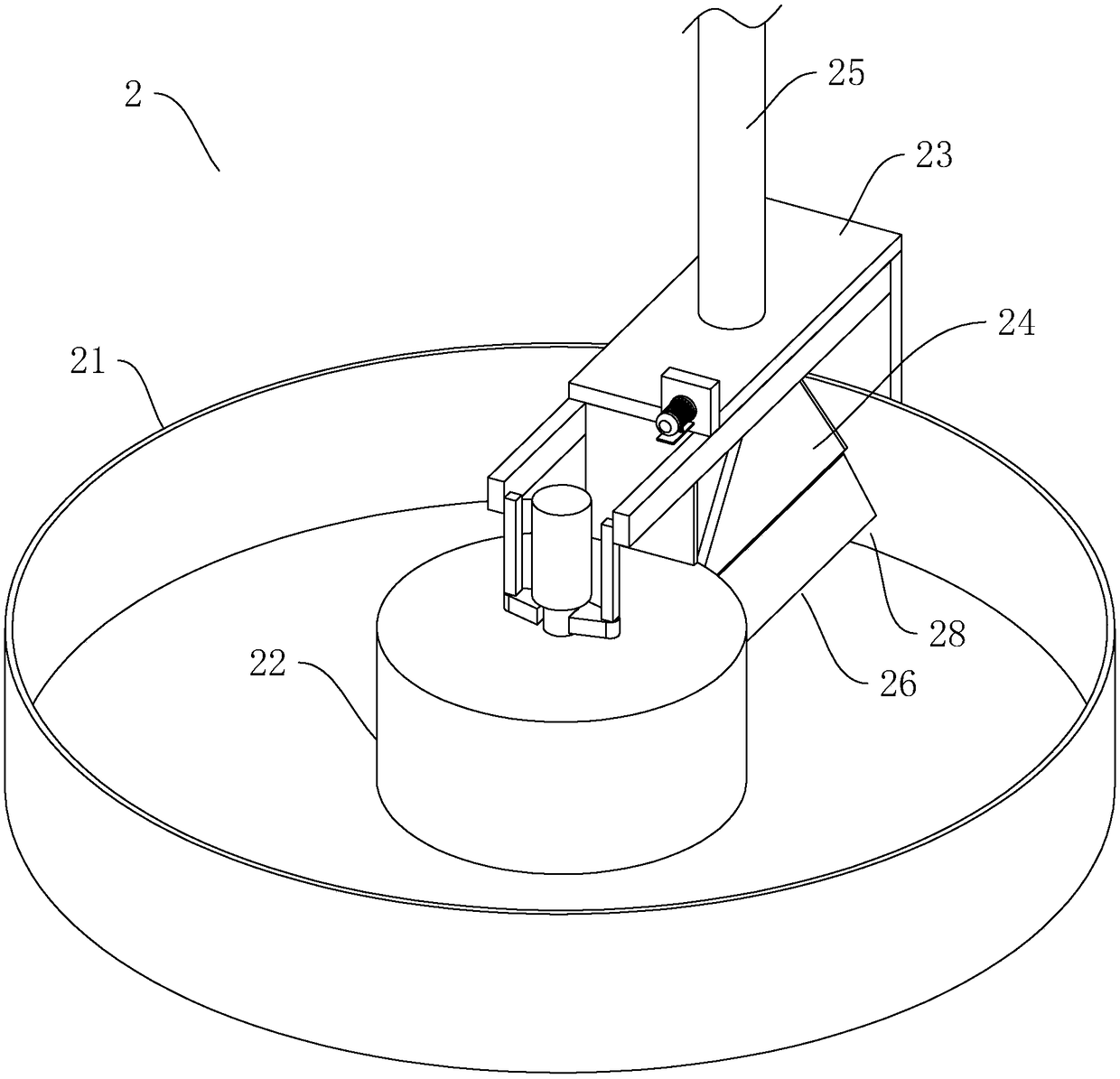

[0035] Such as figure 1 As shown, a cleaning system for viscose yarn includes an opening and mixing device 1, a feeding device 2, a cleaning machine 3 and a cleaning machine 4 arranged in sequence, wherein the cleaning system between the cleaning machine 3 and the cleaning machine 4 And the discharge end of the cleaning machine 4 is provided with a transport air duct 5 .

[0036] When the above cleaning system is used to process the cotton sheets, after selecting the cotton sheets of different materials or colors according to a certain ratio, all the cotton sheets are placed in the opening and mixing device 1, and the opening and mixing device 1 is used to The cotton sheets are opened and mixed. Then, the shredded cotton block is transported into the impurity remover 3 through the feeding device 2, and the impurities in the cotton block are removed by the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com