Preparing method of multi-layer tension surface fiber mat and fiber mat

A fiber pad and tension technology, applied in the field of fiber pads, can solve the problems of poor elasticity and easy collapse of fiber pads, and achieve the effects of improving anti-collapse performance, ensuring light weight, and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

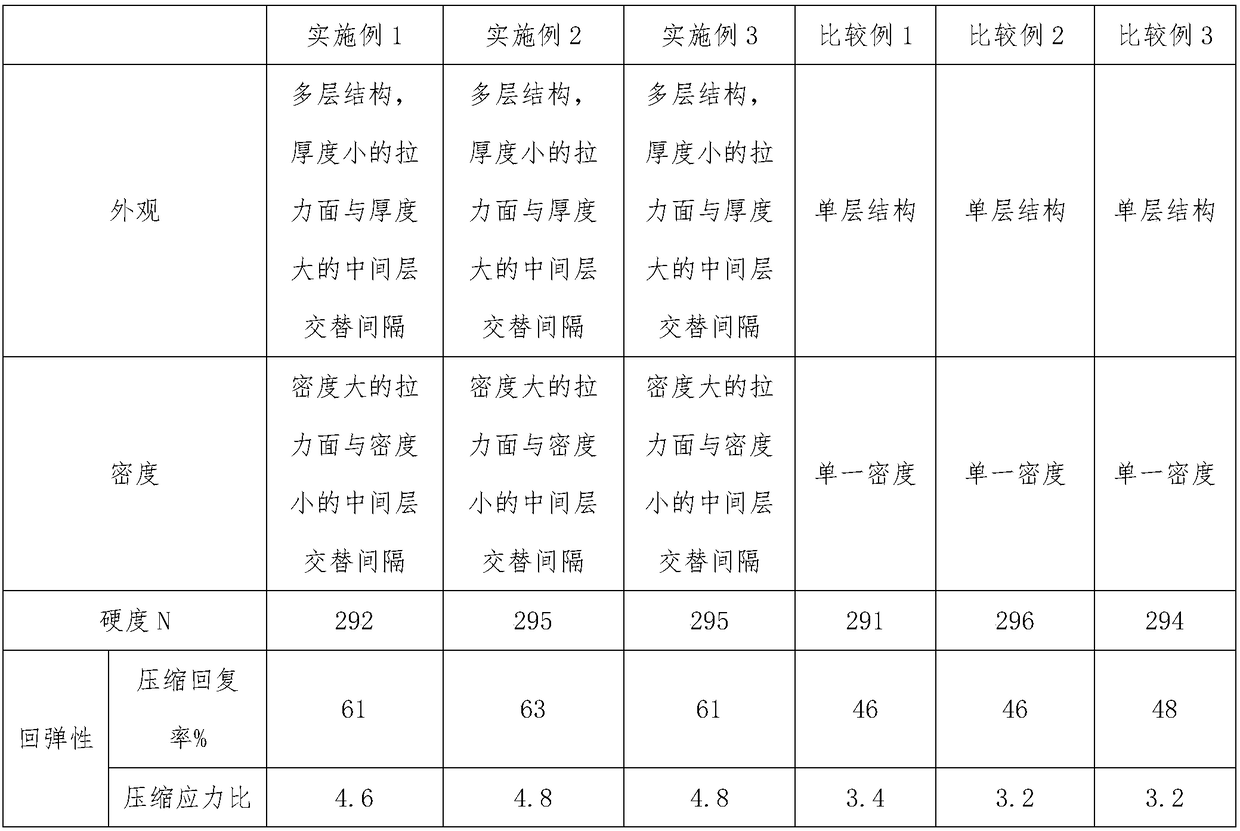

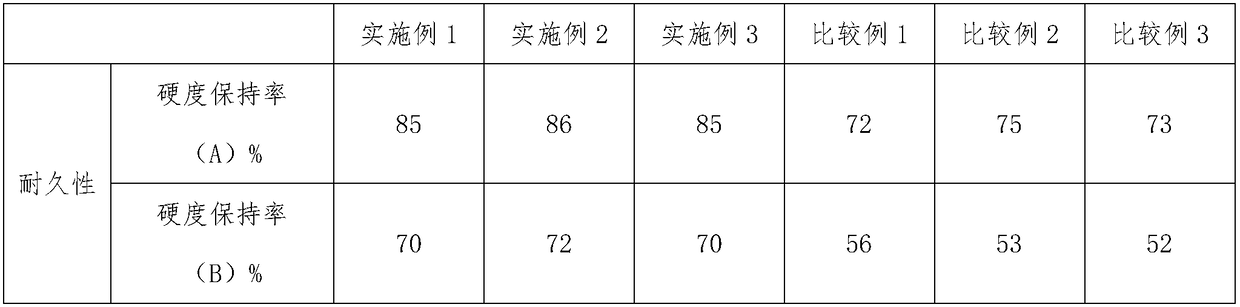

Examples

Embodiment 1

[0022] This embodiment provides a method for preparing a fiber mat, comprising the following steps:

[0023] Firstly, each fiber bundle in the raw material is opened by using a fiber opener to obtain raw material fibers after opening. The raw material fiber used is an elastomer fiber, and the elastomer fiber is a three-dimensional crimped hollow fiber with a melting point of about 100°C.

[0024] The second step is to use a fiber carding machine to card the opened fibers to eliminate entanglement.

[0025] The third step is to use a web laying machine to spread the carded fibers evenly. After being carded into a uniform fiber web by a fiber carding machine, a continuous fiber mesh structure with multiple layers is formed by superimposing the inclined plane of the web and the action of negative pressure air, and is continuously output.

[0026] The fourth step is needle punching. The multi-layer fiber web is transported to the needle punching machine. The needle punching incl...

Embodiment 2

[0031] The main method and steps of embodiment 2 are similar to embodiment 1, and the difference is that the elastomer fiber used is the elk fiber (a kind of polyester buffer fiber with a melting point of about 150 ℃, which differs from ordinary fiber buffer materials in that its fiber arranged vertically). The needling depth is 15mm, the speed is 7.5m / min, and the needling density is 480 pricks / cm 2 . During hot pressing, the heating temperature is 220° C., the wind speed is 60 m / s, and the fiber mat is pressed to a thickness of 6 cm.

Embodiment 3

[0033] The main method and steps of Example 3 are similar to Example 1, except that the elastomer fiber used is polyetherester fiber (PP fiber) with a melting point of about 120°C. The needling depth is 12mm, the speed is 6.5m / min, and the needling density is 350 pricks / cm 2 . During hot pressing, the heating temperature is 150° C., the wind speed is 35 m / s, and the fiber mat is pressed to a thickness of 10 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com