Net belt type sintering furnace

A sintering furnace, mesh belt type technology, applied in the furnace, charge, furnace components and other directions, can solve the problems of difficult control, large temperature fluctuation, affecting the sintering quality, etc., to avoid temperature channeling, avoid the effect of different tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

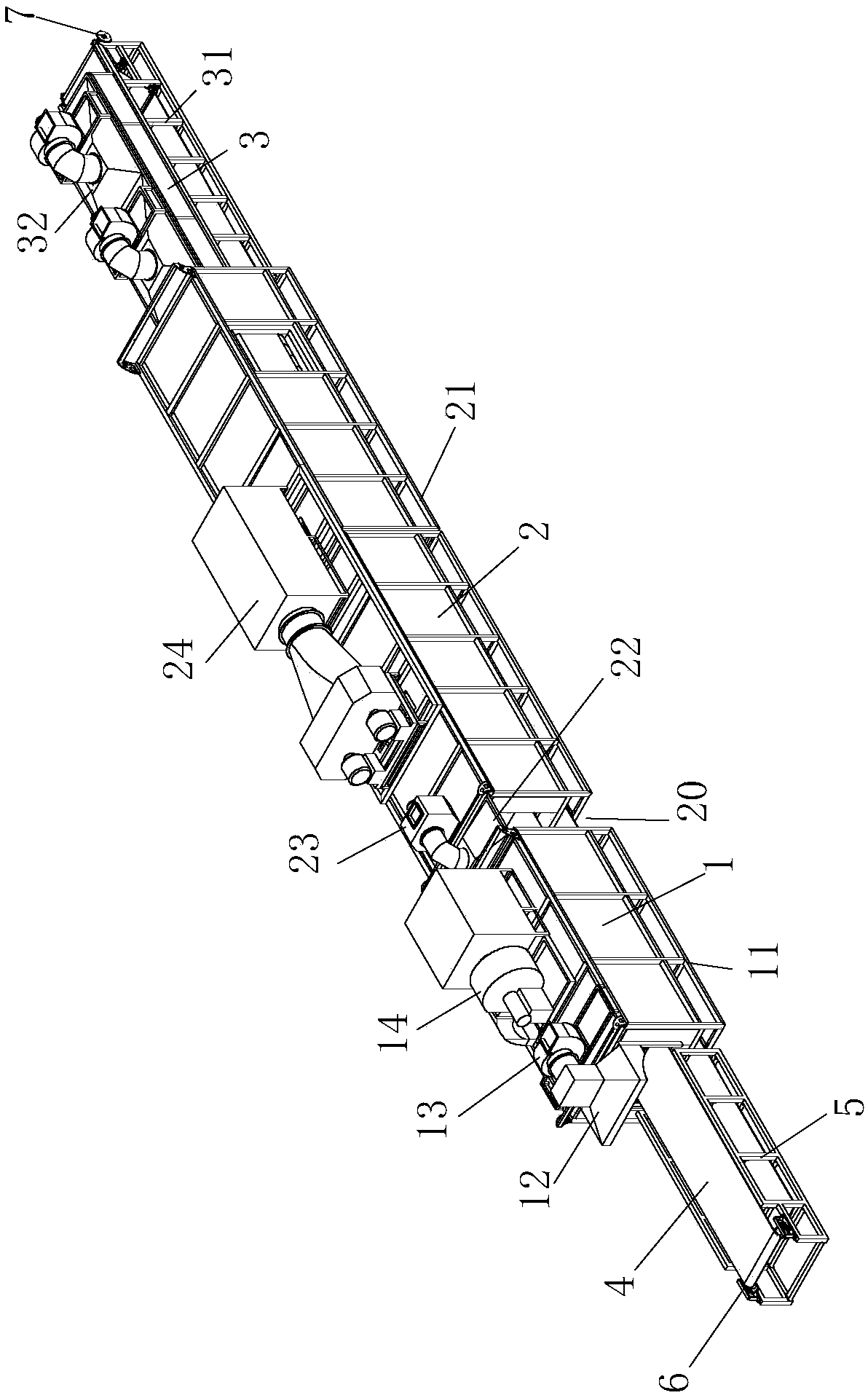

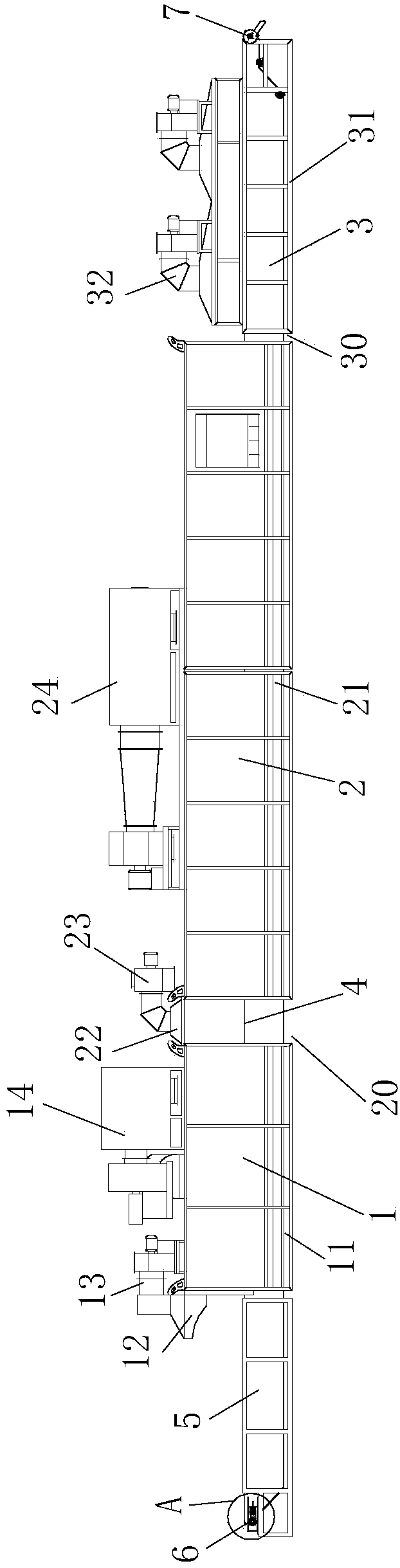

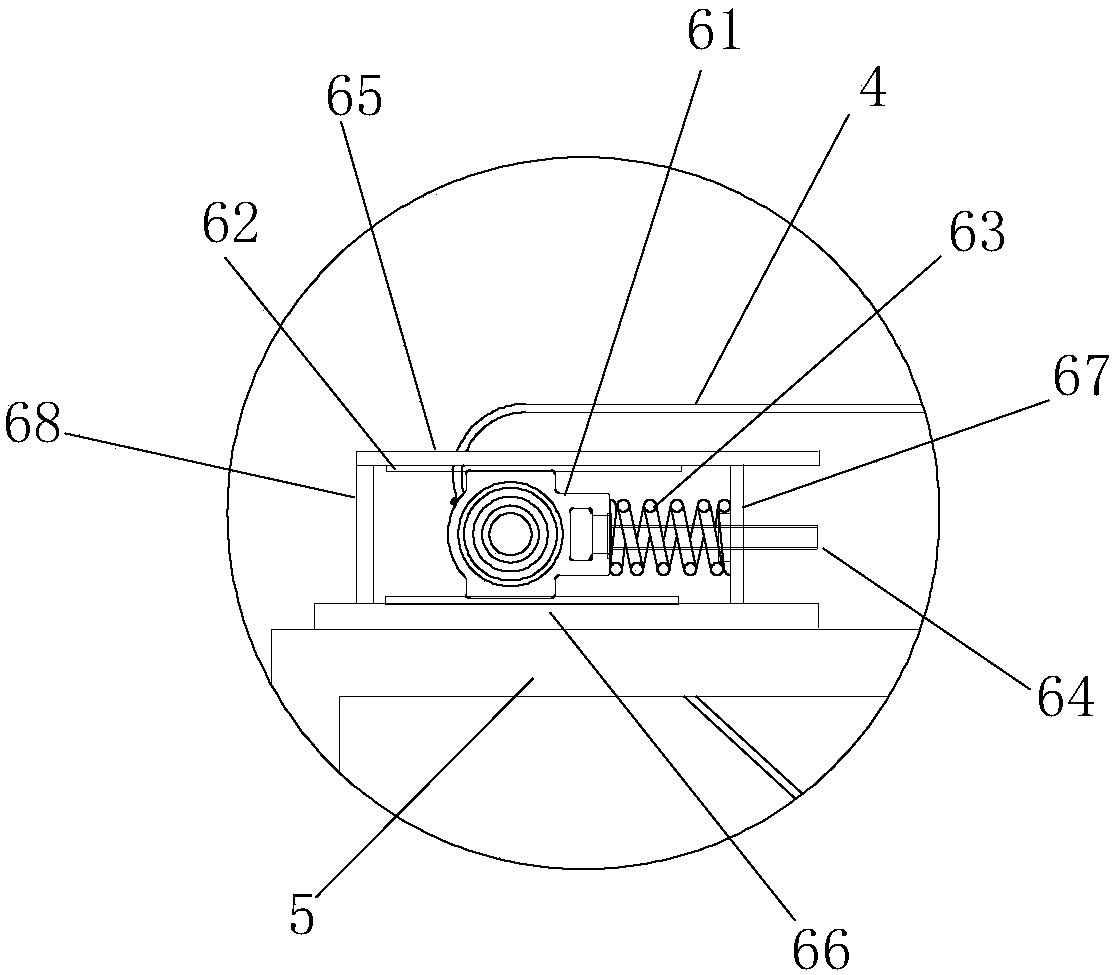

[0015] Example 1 as Figure 1 to Figure 2 As shown, the mesh belt sintering furnace of this embodiment includes a preheating section furnace body 1, a sintering section furnace body 2 and a cooling section furnace body 3, the preheating section furnace body 1 is arranged in the preheating section frame 11, and the sintering section furnace The body 2 is arranged in the frame 21 of the sintering section, the furnace body 3 of the cooling section is arranged in the frame 31 of the cooling section, and the front end of the furnace body 1 of the preheating section is provided with a frame 5 of the feeding section, the frame 5 of the feeding section, the furnace body of the preheating section 1. The furnace body 2 of the sintering section and the furnace body 3 of the cooling section are placed on the same straight line; the front end of the feeding section frame 5 is provided with a passive roller assembly 6, the rear end of the cooling section frame 31 is provided with a driving r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com