Laser ultrasonic detection device and additive manufacturing and detection integrated equipment

A technology of laser ultrasonic and detection device, applied in the field of additive manufacturing, can solve the problem that the positioning accuracy needs to be further improved or not considered, and achieve the effect of improving the effect, improving the accuracy and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: laser ultrasonic detection device

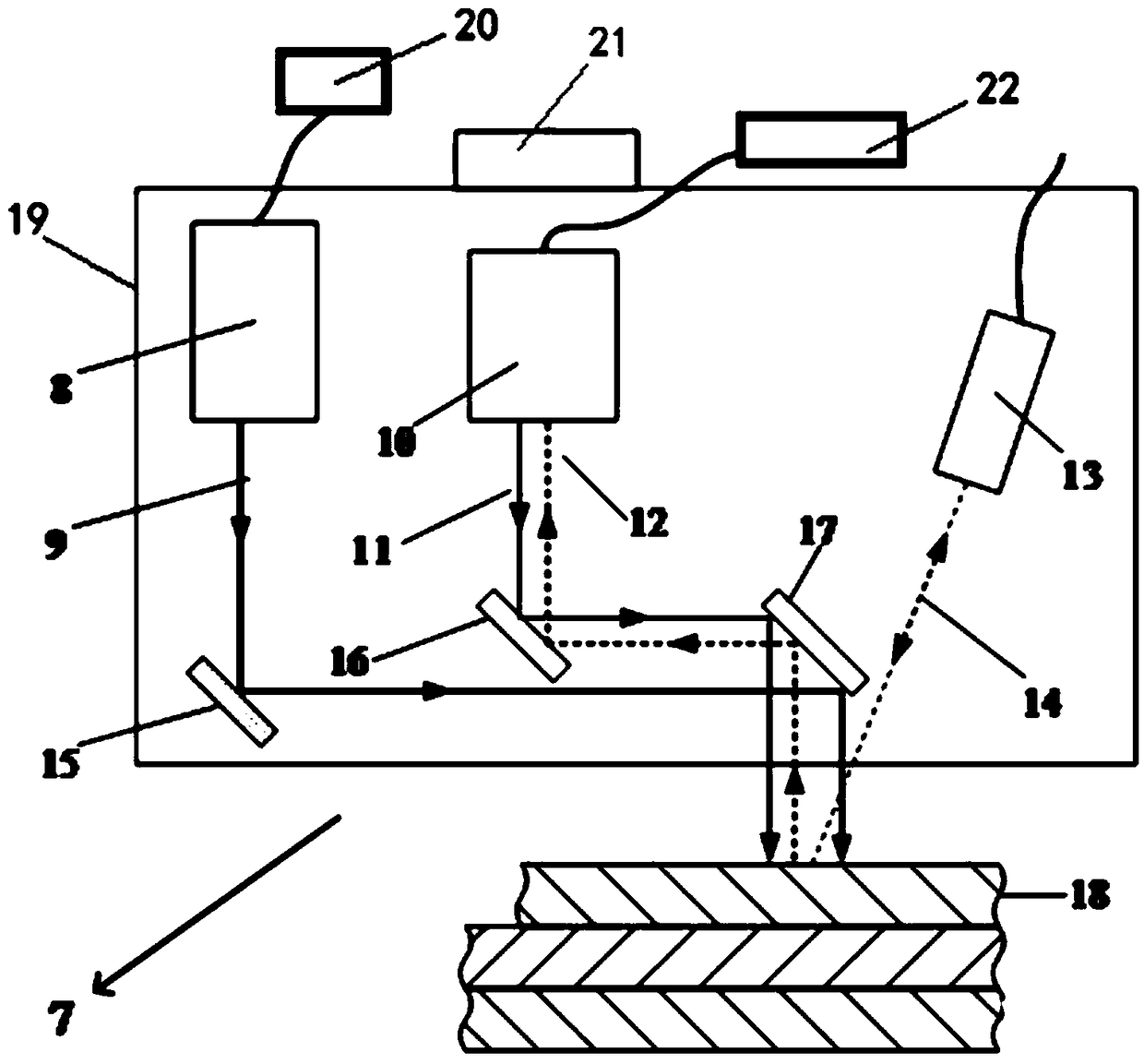

[0042] In order to improve the accuracy of non-destructive testing of internal defects of additive parts, the present invention provides a laser ultrasonic testing device, such as figure 1 As shown, it includes a laser ultrasonic detection probe 7, an excitation laser 20 and a laser ultrasonic receiver 22;

[0043] The laser ultrasonic detection probe 7 includes a housing 19, a focusing probe 8 arranged in the housing 19, a mirror 15, a receiving probe 10, a first lens 16, a second lens 17 and an infrared thermometer 13;

[0044] Wherein, the excitation laser 20 and the laser ultrasonic receiver 22 are arranged outside the housing; the laser ultrasonic receiver 22 includes a detection laser and a laser interferometer;

[0045] The focusing probe 8 is connected to an external excitation laser 20 through an optical fiber, and the receiving probe 10 is connected to an external laser ultrasonic receiver 22 through an optical...

Embodiment 2

[0050] Example 2: Integrated equipment for additive manufacturing and testing

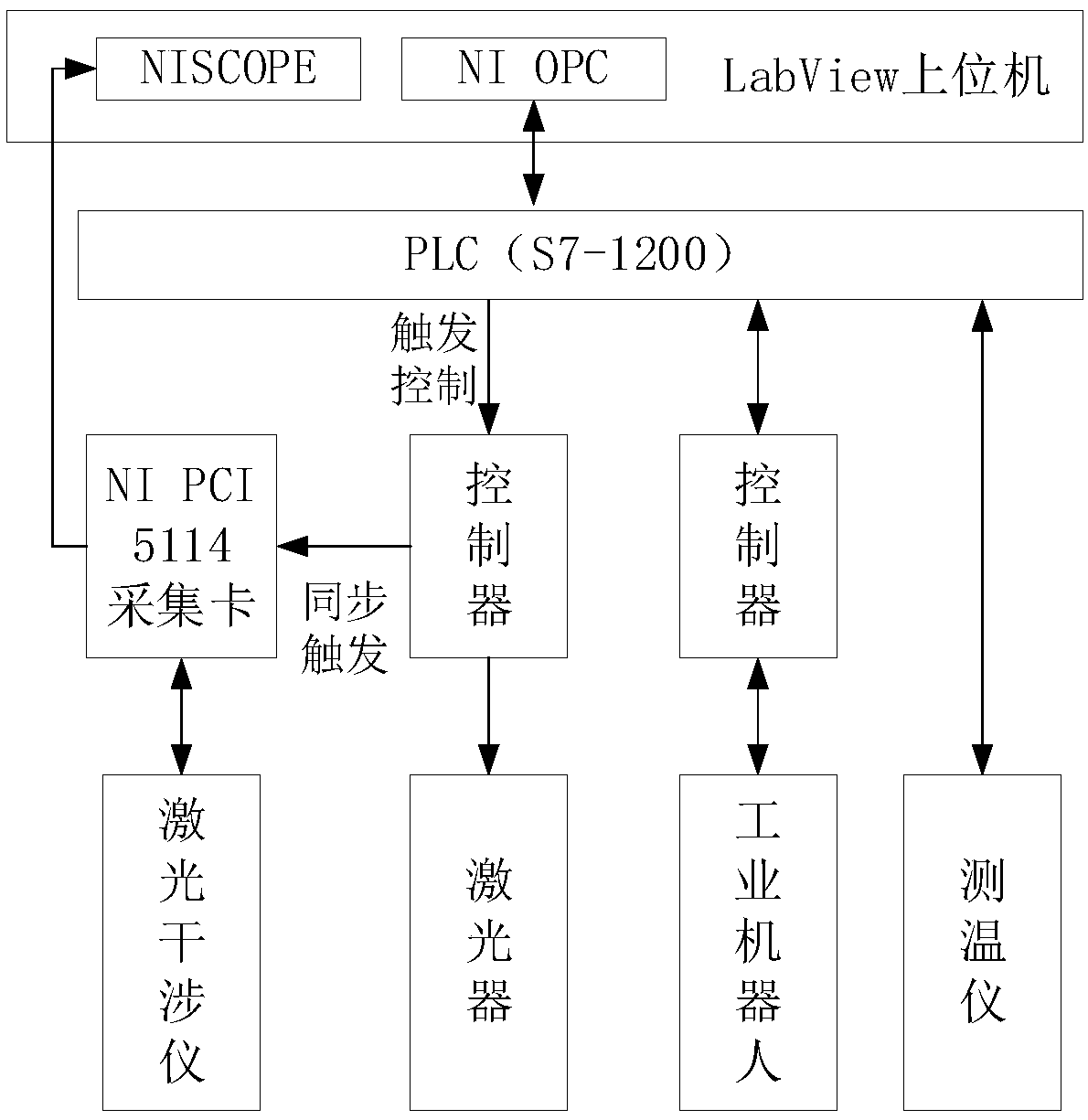

[0051] The following is an introduction to the equipment from the three aspects of additive manufacturing, the mechanical structure of the detection integrated equipment, the control structure and the detection process:

[0052] mechanical structure

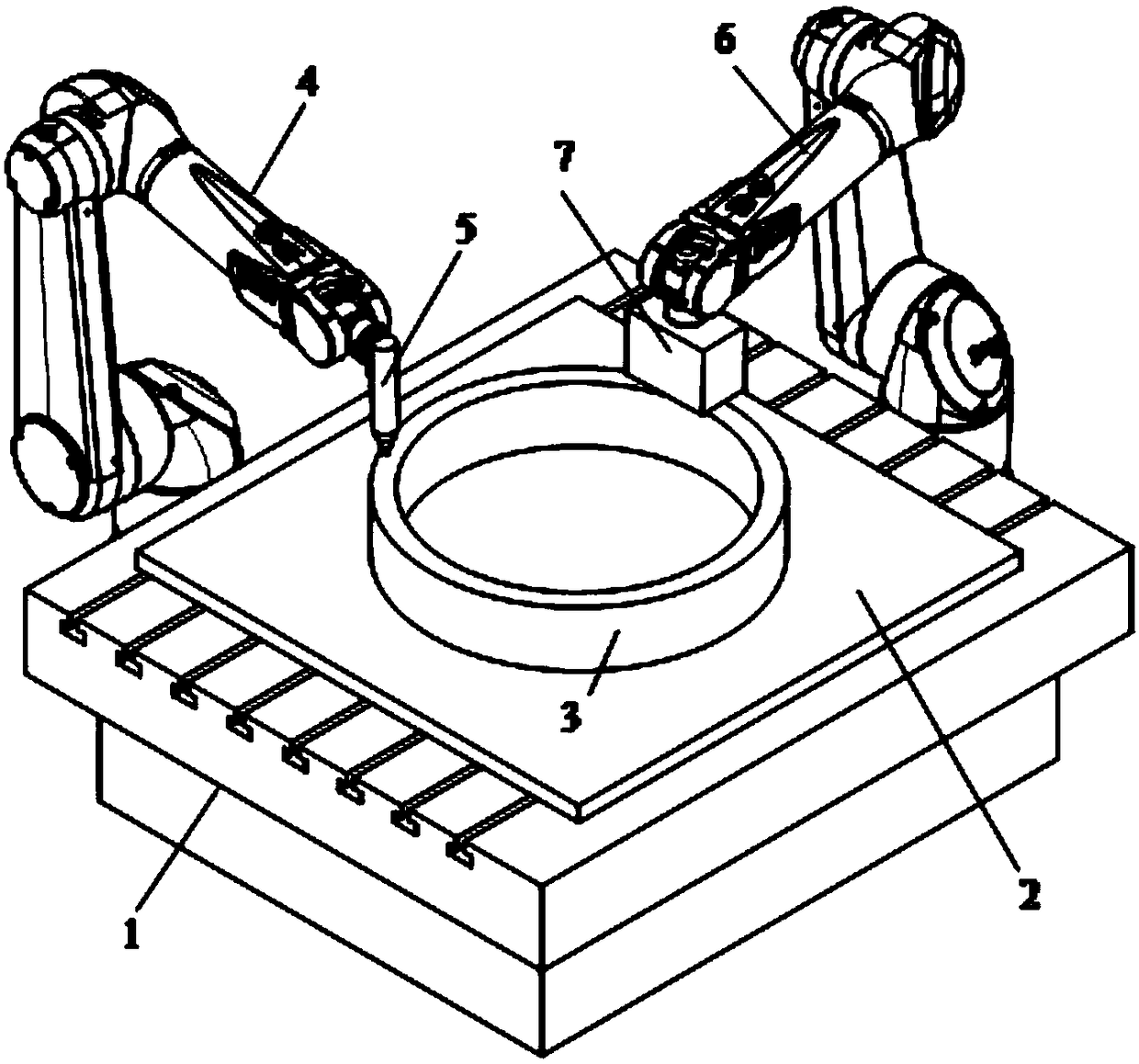

[0053] as attached figure 2 As shown, the equipment includes a first robot (in this embodiment, a welding robot 4), a second robot (in this embodiment, an industrial robot 6), a CMT welding torch 5, the laser ultrasonic testing device provided in Embodiment 1, Control unit and upper computer;

[0054] The workbench 1 is fixed on the ground, and the base plate 2 is fixed on the workbench 1 to form a work platform. The welding robot 4 is fixed on the ground or slide rails (not shown in the figure), and a CMT welding torch 5 is installed at the end. The welding robot 4 carries the CMT welding torch 5 to move, and accumulates and consolidates materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com