Pneumatic friction nano-generator and sensor and sensing method in pneumatic system

A nano-generator and pneumatic system technology, applied in the field of sensors, can solve the problems of inability to monitor the working state, low integration, and complicated manufacturing process of the sensor working principle, and achieve the effect of simple structure, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, a specific friction power generation component is taken as an example to introduce the pneumatic friction nanogenerator of the present invention in detail.

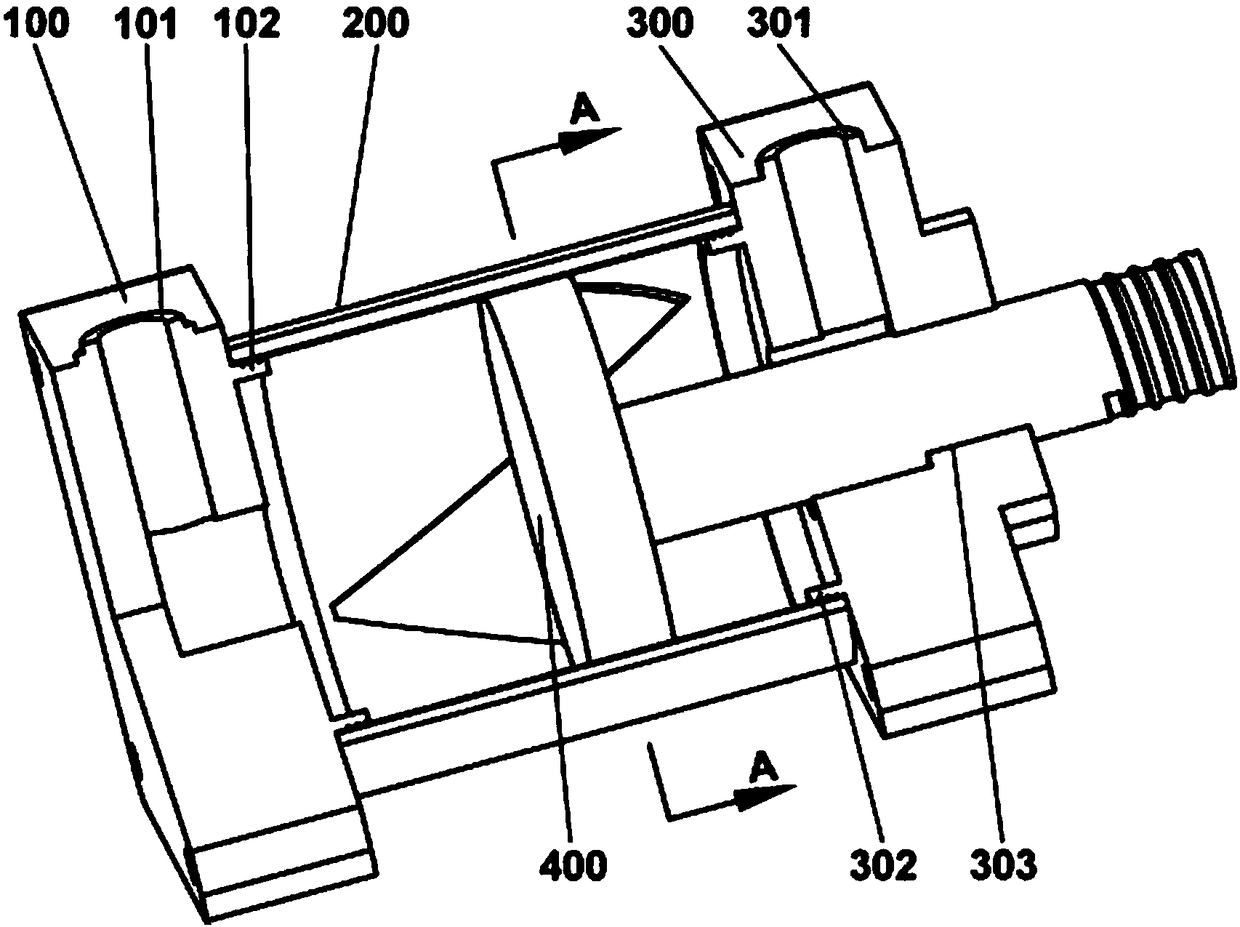

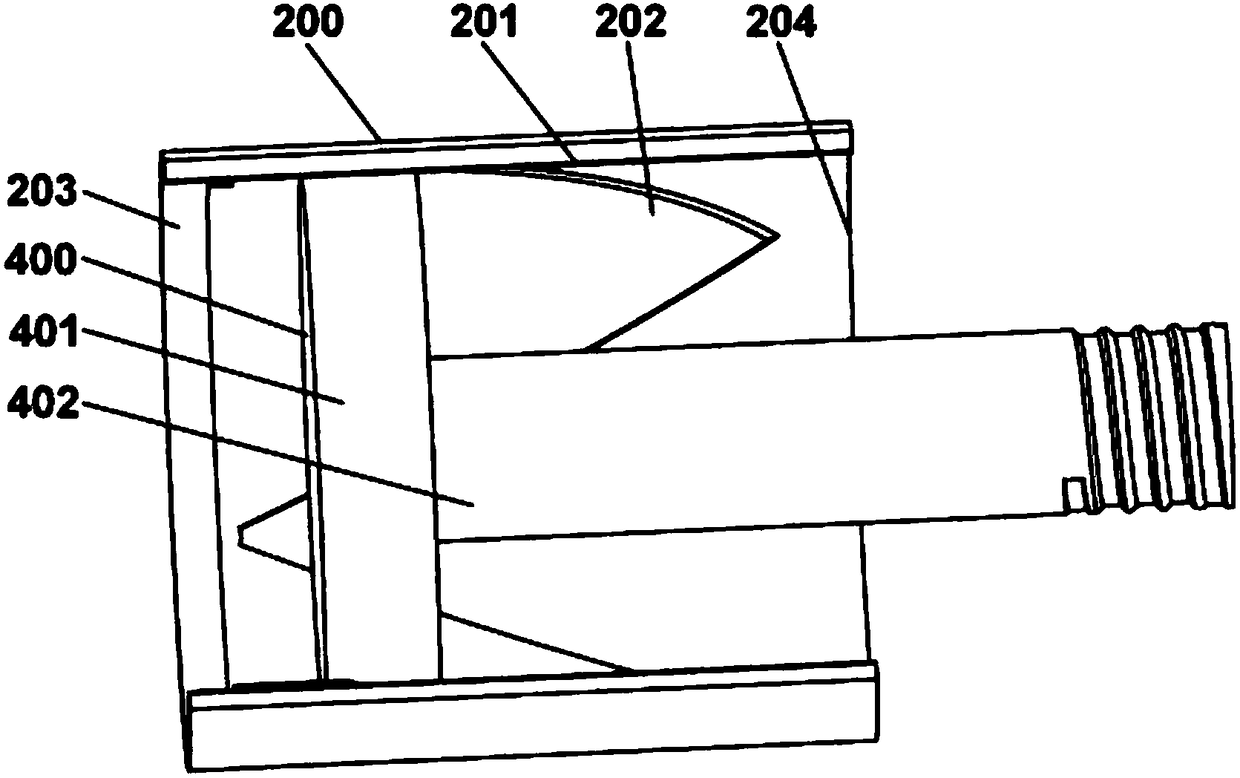

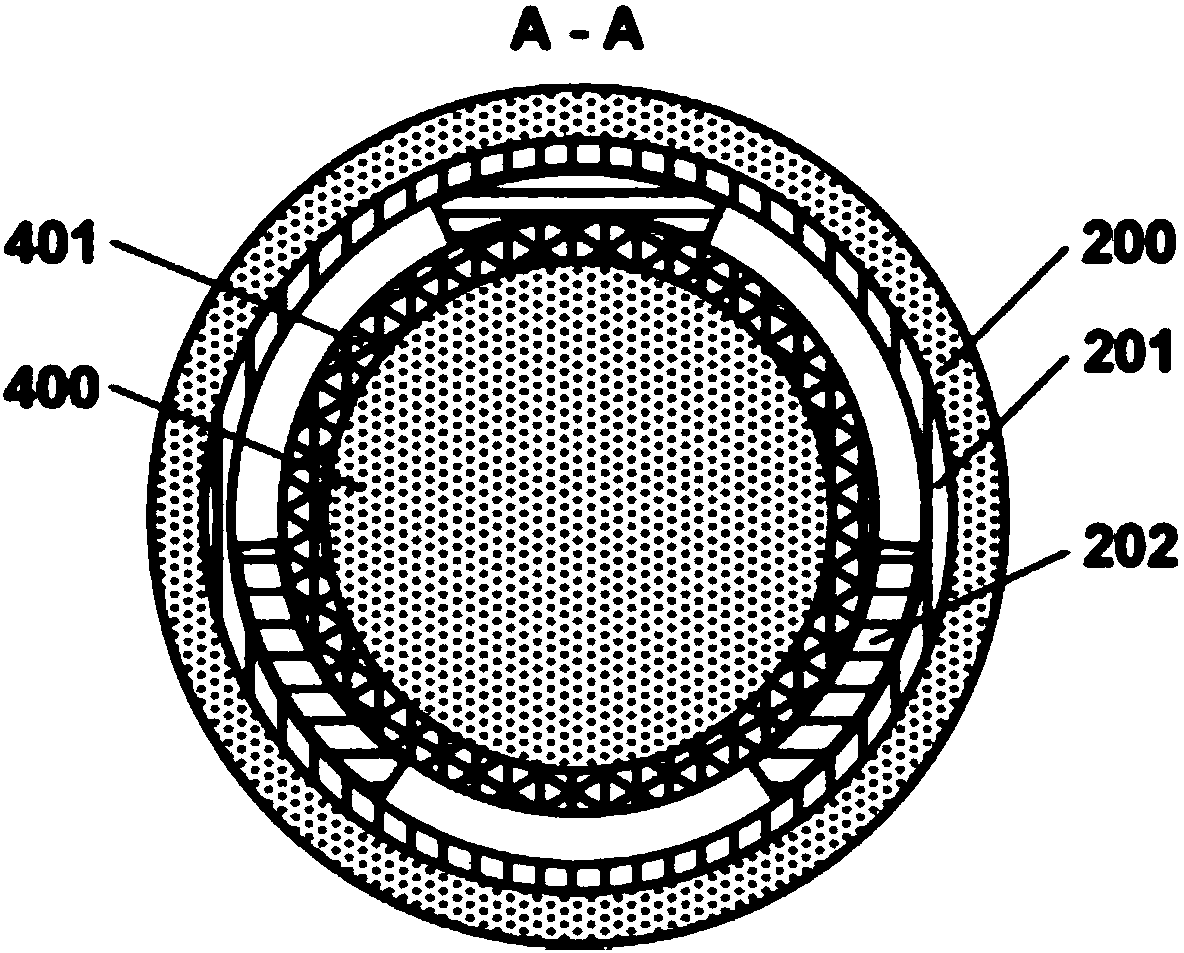

[0049] figure 1 It is a schematic cross-sectional view of the structure of the pneumatic friction nanogenerator according to the embodiment of the present invention. Such as figure 1 As shown, the pneumatic friction nanogenerator of the present invention includes a left end cover 100 , a cylinder body 200 , a right end cover 300 and a piston 400 . The left end cap 100 and the right end cap 300 are threadedly connected with the cylinder body 200 respectively, and the piston 400 is arranged inside the cylinder body 200 and can slide relative to the cylinder body 200 . The side of the left end cover 100 is provided with a first air inlet 101, the compressed gas can enter the cylinder body 200 through the first air inlet 101, and acts on the left end surface of the piston 400 to make the piston 40...

Embodiment 2

[0069] By detecting the electrical signal generated by the pneumatic friction nanogenerator in the first embodiment, the detection of the piston movement position, movement speed, gas pressure, flow rate and other parameters in the pneumatic system can also be realized. Therefore, the present embodiment provides a sensor in a pneumatic system.

[0070] Take the second friction layer as an example of a triangular conductive film below (see Figure 1 to Figure 3 ), respectively describe the different sensing functions of the sensor in detail. The sensing process of sensors with other structures is similar, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com