Green dry forage and rabbit raising method

A dry feed and raw material technology is applied in the field of rabbit breeding to achieve the effects of abundant resources, improved economic benefit and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

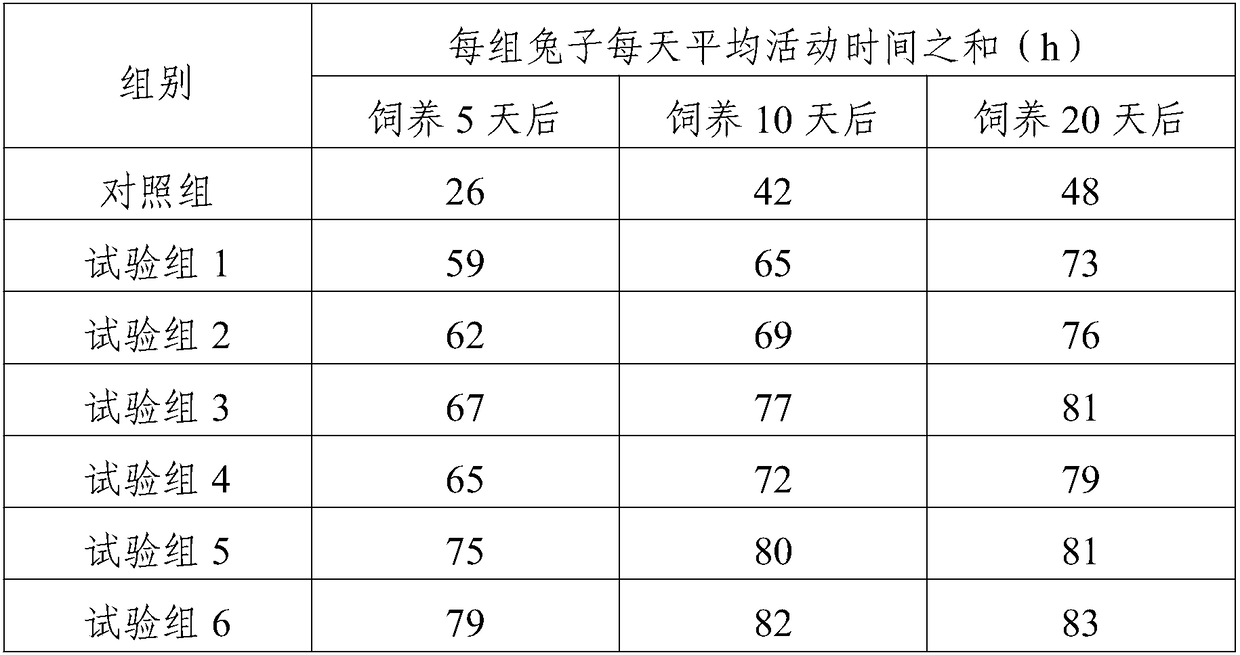

Image

Examples

Embodiment 1

[0027] A dry green feed, comprising the following raw materials in parts by weight: 7 parts of Elymus, 22 parts of alfalfa, 10 parts of sweet clover, 8 parts of Sudan grass, 6 parts of bromegrass, 7 parts of wheatgrass, and 12 parts of oat straw , 14 parts of green corn stalks, 9 parts of ryegrass, 38 parts of wedelia, 10 parts of corn flour, 17 parts of soybean meal, 15 parts of bran, 5 parts of bone meal, 1 part of fish meal, 12 parts of stone powder, and 1 part of table salt.

Embodiment 2

[0029] A dry green feed, comprising the following raw materials in parts by weight: 15 parts of Elymus, 18 parts of alfalfa, 17 parts of sweet clover, 6 parts of Sudan grass, 11 parts of bromegrass, 5 parts of wheatgrass, and 16 parts of oat straw , 12 parts of green corn stalks, 13 parts of ryegrass, 35 parts of wedelia, 16 parts of corn flour, 14 parts of soybean meal, 20 parts of bran, 3 parts of bone meal, 4 parts of fish meal, 9 parts of stone powder, and 3 parts of table salt.

Embodiment 3

[0031] A dry green feed, comprising the following raw materials in parts by weight: 8 parts of Elymus, 25 parts of alfalfa, 12 parts of sweet clover, 9 parts of Sudan grass, 7 parts of bromegrass, 8 parts of wheatgrass, and 13 parts of oat straw , 15 parts of green corn stalks, 10 parts of ryegrass, 40 parts of wedelia, 13 parts of corn flour, 18 parts of soybean meal, 17 parts of bran, 8 parts of bone meal, 2 parts of fish meal, 13 parts of stone powder, and 2 parts of table salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com