A continuous liquid phase reactor and a process for producing liquid sodium silicate using the reactor

A technology of liquid phase reactor and liquid sodium silicate, which is applied in chemical instruments and methods, silicate, alkali metal silicate, etc., can solve the problems of low degree of automation, waste of raw materials, and large number of reactors, and achieve The effect of reducing consumption and cost and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

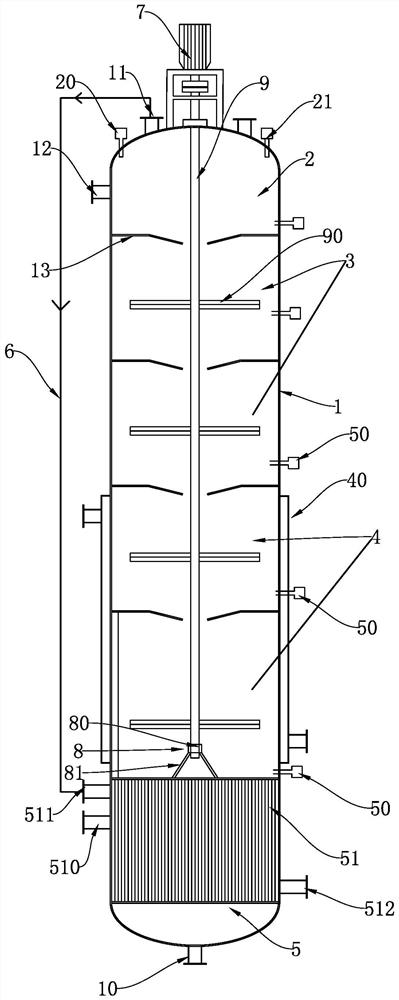

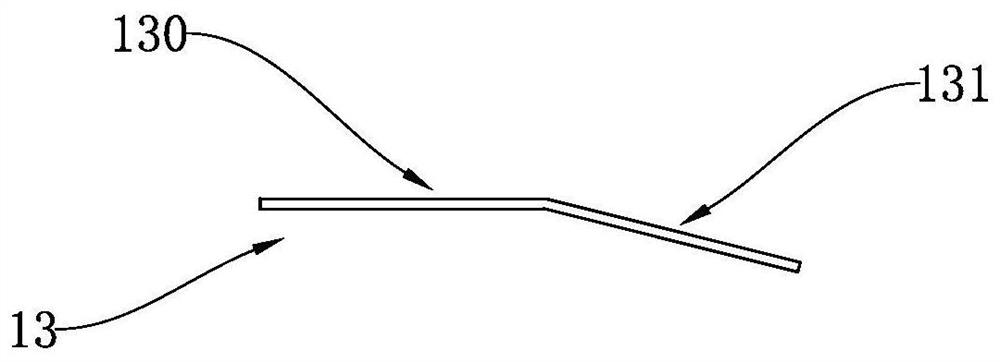

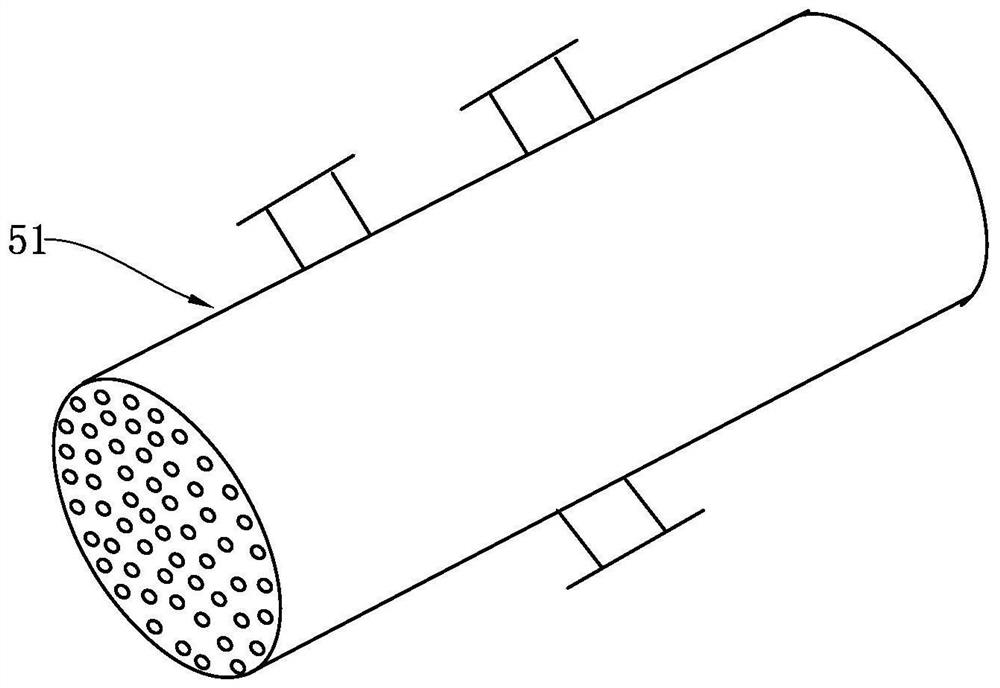

[0036] A continuous liquid phase reactor for the production of liquid sodium silicate, such as figure 1 , figure 2 and image 3 Commonly shown, including a reactor body 1, the bottom of the reactor body is provided with a feed port 10, the top of the reactor body 1 is provided with an exhaust port 11, and one side of the upper part of the reactor body 1 is provided with a discharge port 12, The inside of the reactor body 1 is provided with a multi-layer partition 13, and the partition 13 divides the reactor body 1 from top to bottom into a settling zone 2, a heat preservation reaction zone 3, an exothermic reaction zone 4 and a preheating zone 5 (reaction The diameter-to-height ratio of the vessel is 1:3-6, the volume ratio of the preheating zone, exothermic reaction zone, thermal insulation reaction zone and settling zone is 1:1.5-2.5:1.5-2.5:0.5-1.5), and the inside of the reactor body 1 A stirring device is provided, and the stirring device passes through the settling zo...

Embodiment 2

[0046] A kind of process utilizing continuous liquid phase reactor to produce liquid sodium silicate, comprises the following steps:

[0047] (1) Reaction material quartz sand (SiO 2 content of more than 99.2%), hollow microspheres and caustic soda solution are mixed (the molar ratio of quartz sand, hollow microspheres and caustic soda solution is 1.2:0.3:1) enter the preheating zone of the liquid phase reactor from the feeding port, and control the preheating The reaction temperature in the zone is 80°C, and the reaction materials enter the exothermic reaction zone after preheating, start the stirring device, and control the speed of the stirring device to 60 rpm;

[0048] (2) After the reaction material enters the exothermic reaction zone, the temperature of the exothermic reaction zone is controlled to be 160° C., and the reaction material enters the heat preservation reaction zone after reacting in the exothermic reaction zone for 1.5-2.5 hours;

[0049] (3) The reaction ...

Embodiment 3

[0053] A kind of process utilizing continuous liquid phase reactor to produce liquid sodium silicate, comprises the following steps:

[0054] (1) Reaction material quartz sand (SiO 2 content of more than 99.2%), hollow microspheres and caustic soda solution are mixed (the molar ratio of quartz sand, hollow microspheres and caustic soda solution is 2.6:0.6:1) enter the preheating zone of the liquid phase reactor from the feeding port, and control the preheating The reaction temperature in the zone is 90°C, and the reaction materials enter the exothermic reaction zone after preheating, start the stirring device, and control the speed of the stirring device to 70 rpm;

[0055] (2) After the reaction material enters the exothermic reaction zone, the temperature of the exothermic reaction zone is controlled to be 170° C., and the reaction material enters the heat preservation reaction zone after reacting in the exothermic reaction zone for 1.5-2.5 hours;

[0056] (3) The reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com