Safety protection device for continuous casting steel ladle and tundish

A technology of safety protection device and tundish, applied in injection device, casting equipment, casting melt container, etc., can solve the problems of infiltration molten steel, difficulty in ladle turnover, lower production efficiency, etc., to reduce damage and scrap ratio, improve Effective operation rate and improved turnover speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

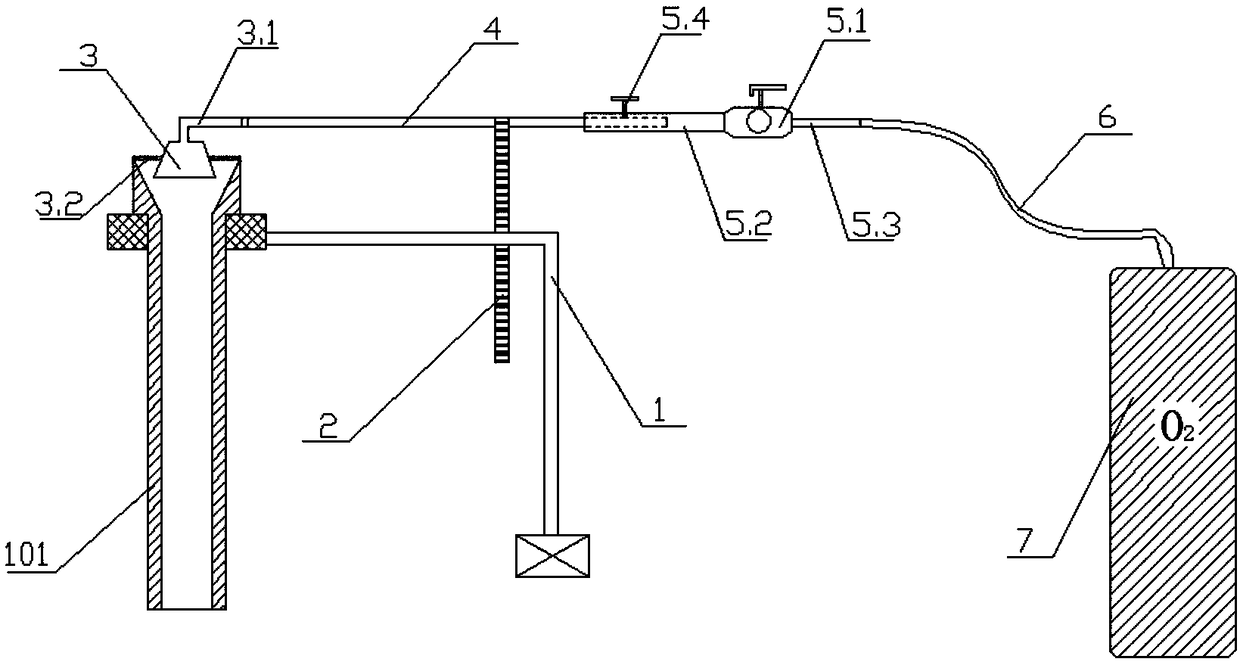

[0042] see Figure 1 to Figure 16 , the invention relates to a safety protection device for a continuous casting ladle and a tundish, including an oxygen burning device, a thermal spraying treatment device, and a tundish impact zone protection device;

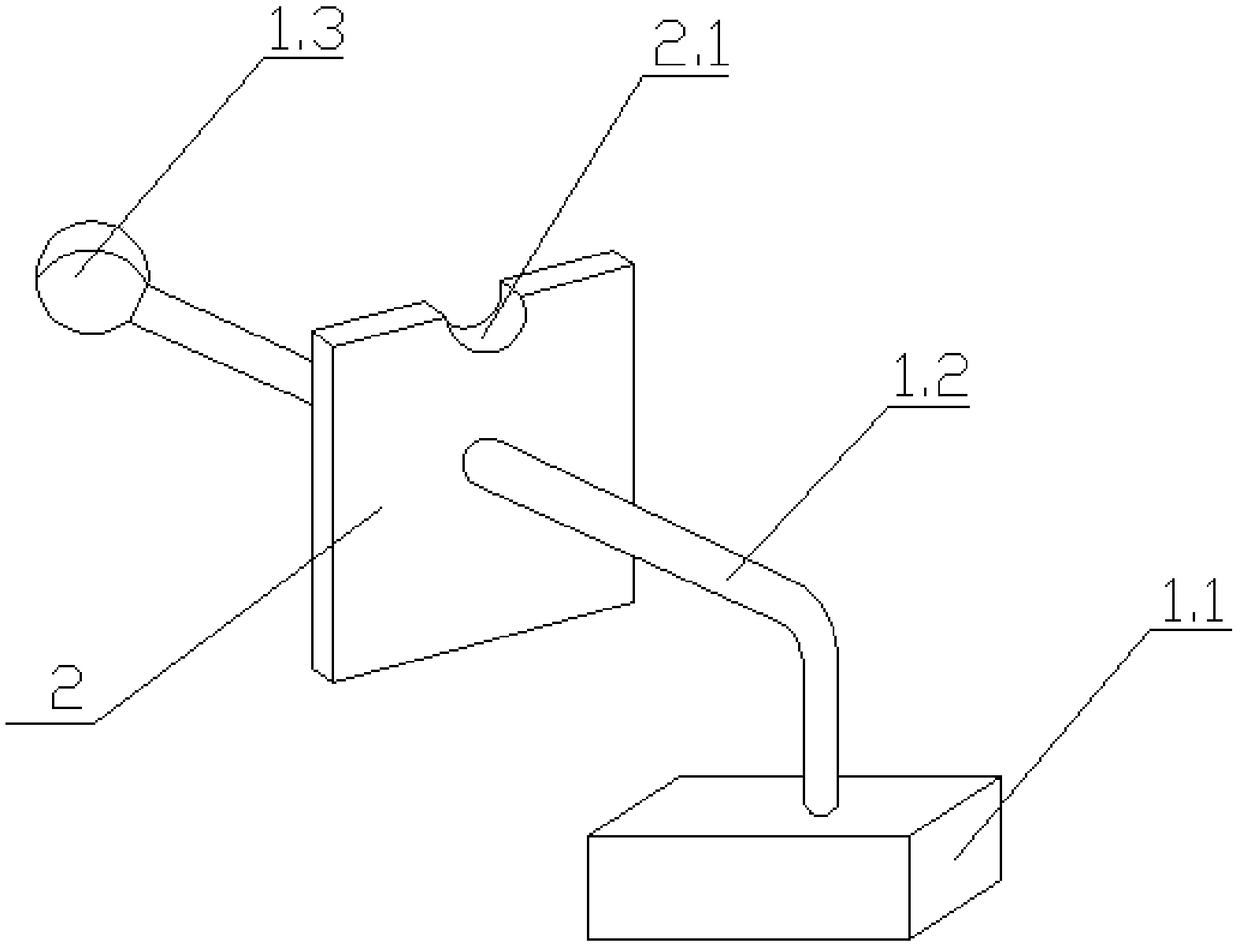

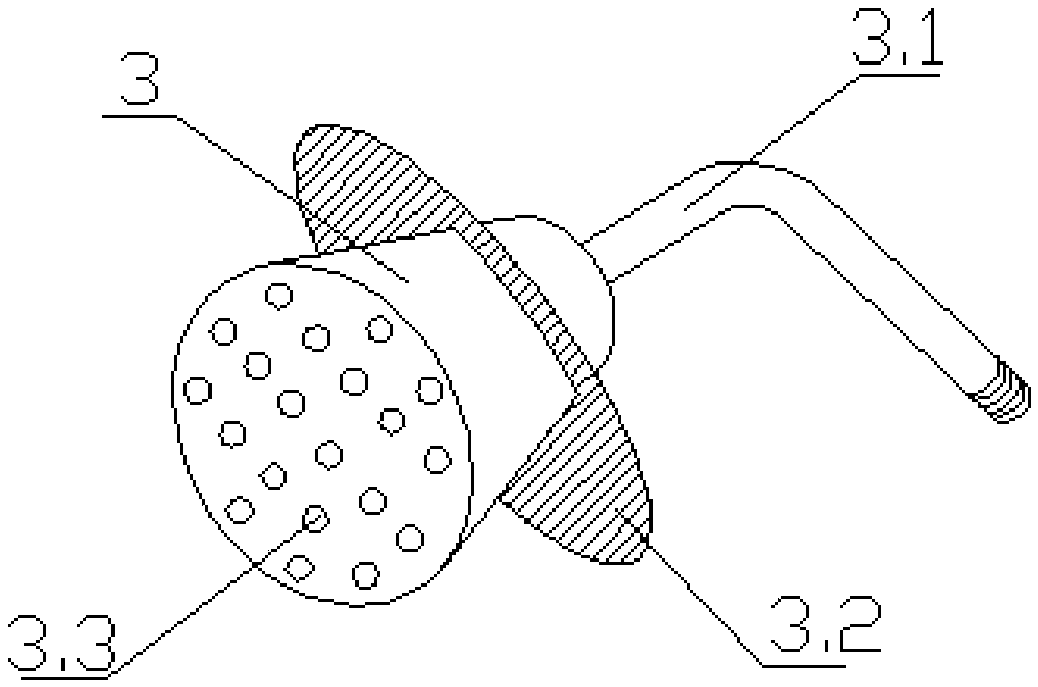

[0043] Wherein the oxygen burning device is provided with a shroud holder 1, which is clamped on the shroud 101, the shroud holder 1 includes a base 1.1, and the clamping arm 1.2 is fixedly installed on the base 1.1, The top of the clamping arm 1.2 is provided with a jaw 1.3, and the jaw 1.3 clamps the shroud 101; the top of the bowl of the shroud 101 is provided with an oxygen burning nozzle 3, and the oxygen burning nozzle 3 is Conical shape, the cross-section of the oxygen-burning nozzle 3 gradually increases from top to bottom, and the interior of the above-mentioned oxygen-burning nozzle 3 is hollow; the outer wall of the oxygen-burning nozzle 3 is provided with an annular flange 3.2, and the annular flange 3.2 and The ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com