Three-axis mobile positioning high-loading integrated machine

A high-load, axis-moving technology, applied in the direction of drive devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of small load, low precision of all-in-one machines, and inability to move multiple axes, so as to achieve sufficient operating power and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

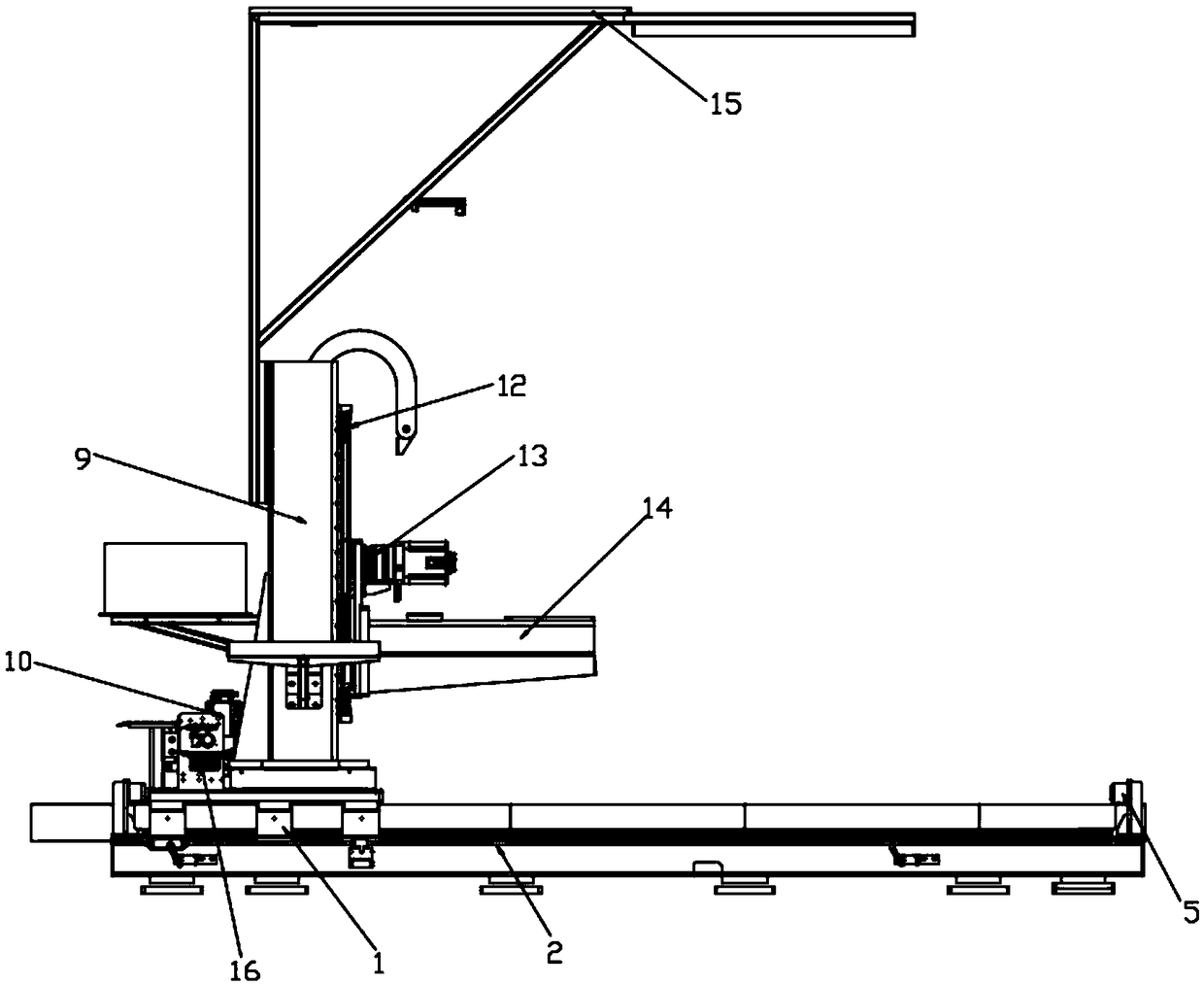

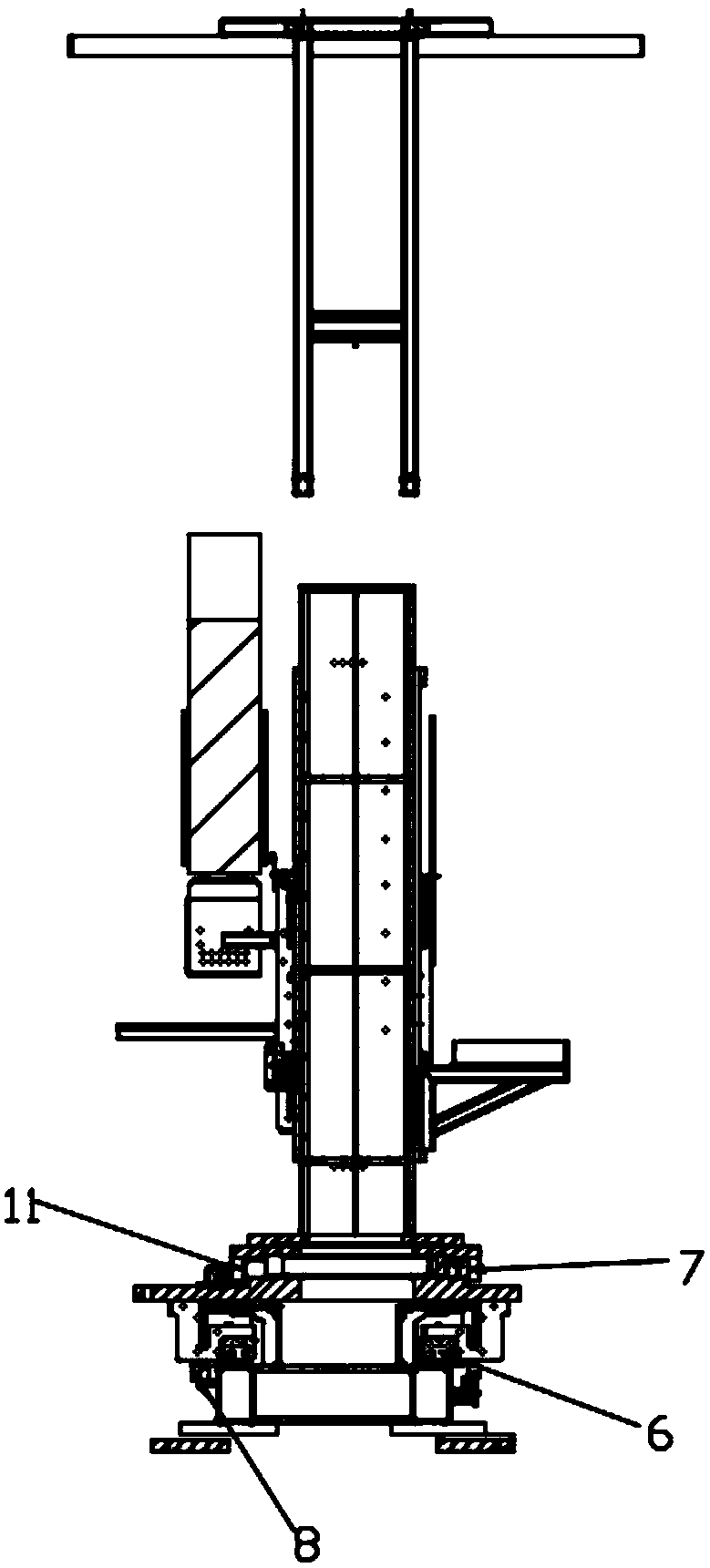

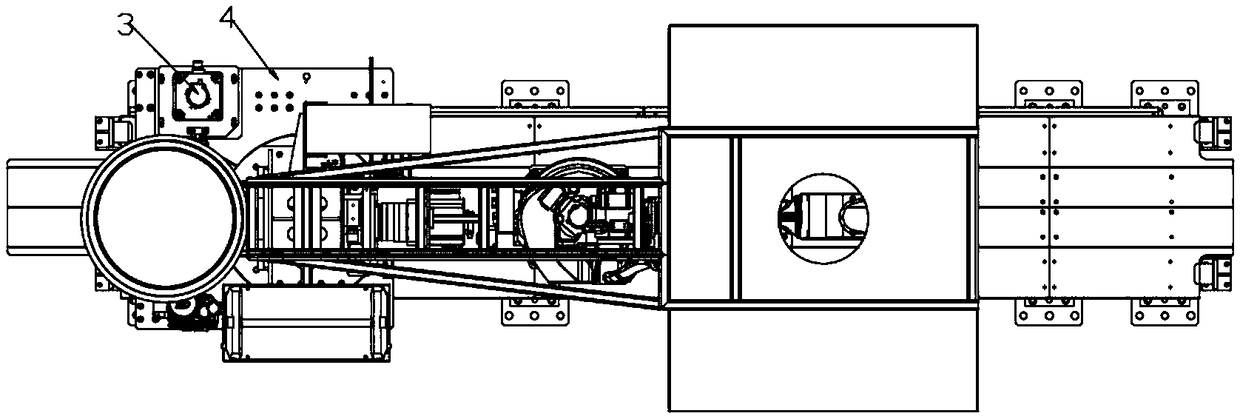

[0026] see Figure 1~5 , in an embodiment of the present invention, a three-axis mobile positioning high-load all-in-one machine, including a slide plate 1, an X-direction travel shaft 2, a first reducer 3, an X-direction mobile slide plate 4, a limit switch 5, a linear guide rail 6, an X To the rack and pinion 8, the third reducer 10, the second reducer 13 and the automatic pressurized grease lubrication system, the linear guide rail 6 is located on the X-direction travel axis 2, and the X-direction moving slide plate 4 passes through the bottom slide plate 1 Slidingly connected with the linear slide rail 6, the X-direction mobile slide plate 4 is fixedly connected with the slide plate 1, the bottom of the slide plate 1 is provided with a first gear 17, and the first reducer 3 is connected to the first gear rack 8 through the X-direction The meshing of the gear 17 drives the X-direction mobile slide plate 4 to move automatically. The X-direction gear rack 8 is located on the ...

Embodiment 2

[0029] The difference between this embodiment of the present invention and Embodiment 1 is that a connecting smoke exhaust bracket 15 and an automatic pressurized grease lubrication system 16 are provided above the Z-direction rotating shaft 9, and the connecting smoke exhaust bracket 15 is located at the top of the device. The automatic pressurized grease lubrication system 16 is located on one side of the third reducer 10 .

[0030] The working principle of the present invention is: when the X-direction walking shaft 2 needs to walk, the first reducer 3 drives the X-direction rack and pinion 8 to move, and can move to the specified position. Or when the tail end hits the limit switch 5, the X-direction mobile slide plate 4 stops; when the Z-direction rotating shaft 9 needs to rotate, the third reducer 10 drives the high-load bearing 7 and the Z-direction rack and pinion 11 to rotate, The second reducer 13 can drive Z to move up and down the moving shaft 14 and stop at any po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com