Stiffened and reinforced magnesium alloy suspended air train body and manufacturing method thereof

A technology for air trains and manufacturing methods, applied in railway car bodies, manufacturing tools, railway car body parts, etc., can solve the problems that limit the large-scale application and sustainable development of aluminum alloys and steel, and do not meet the requirements of safety, efficiency, convenience, and energy saving. Environmental protection, restrictions on the popularization and application of suspended sky trains, etc., to achieve significant shock absorption and noise reduction, solve difficult sustainable development, and improve operational efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

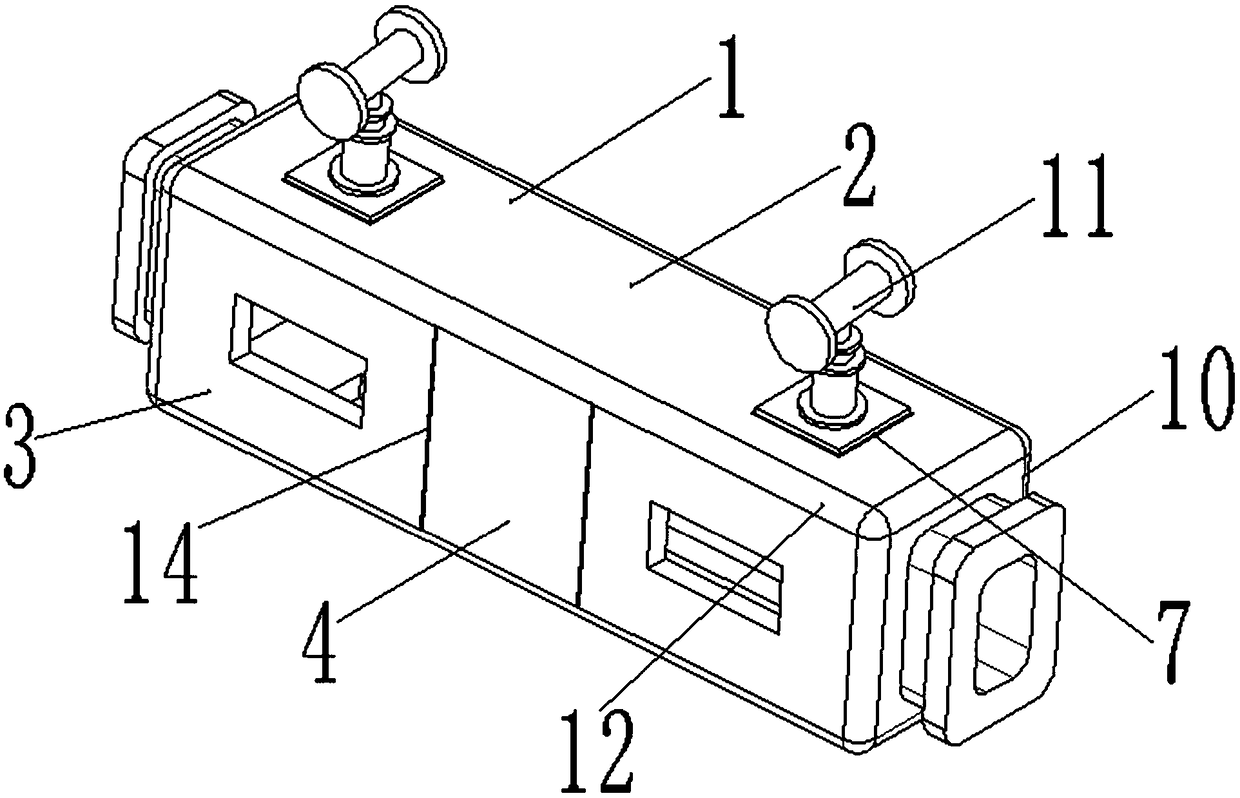

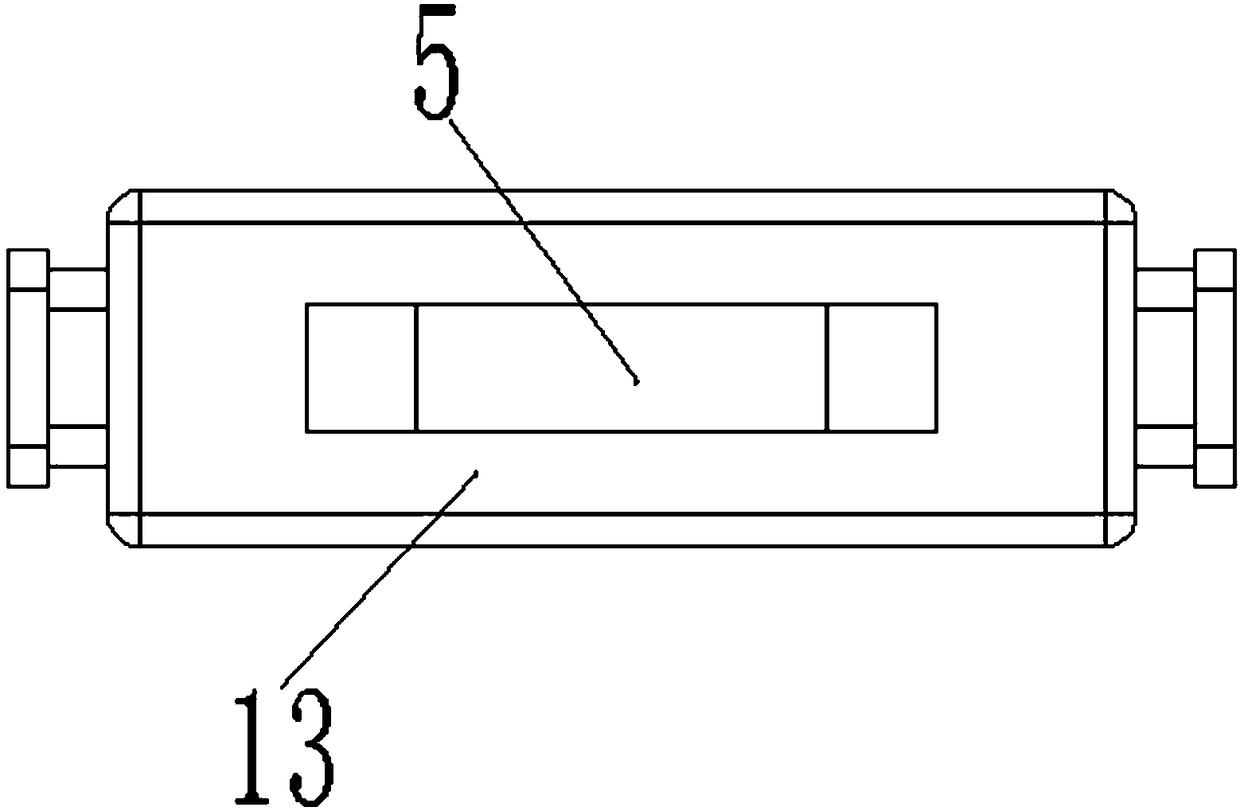

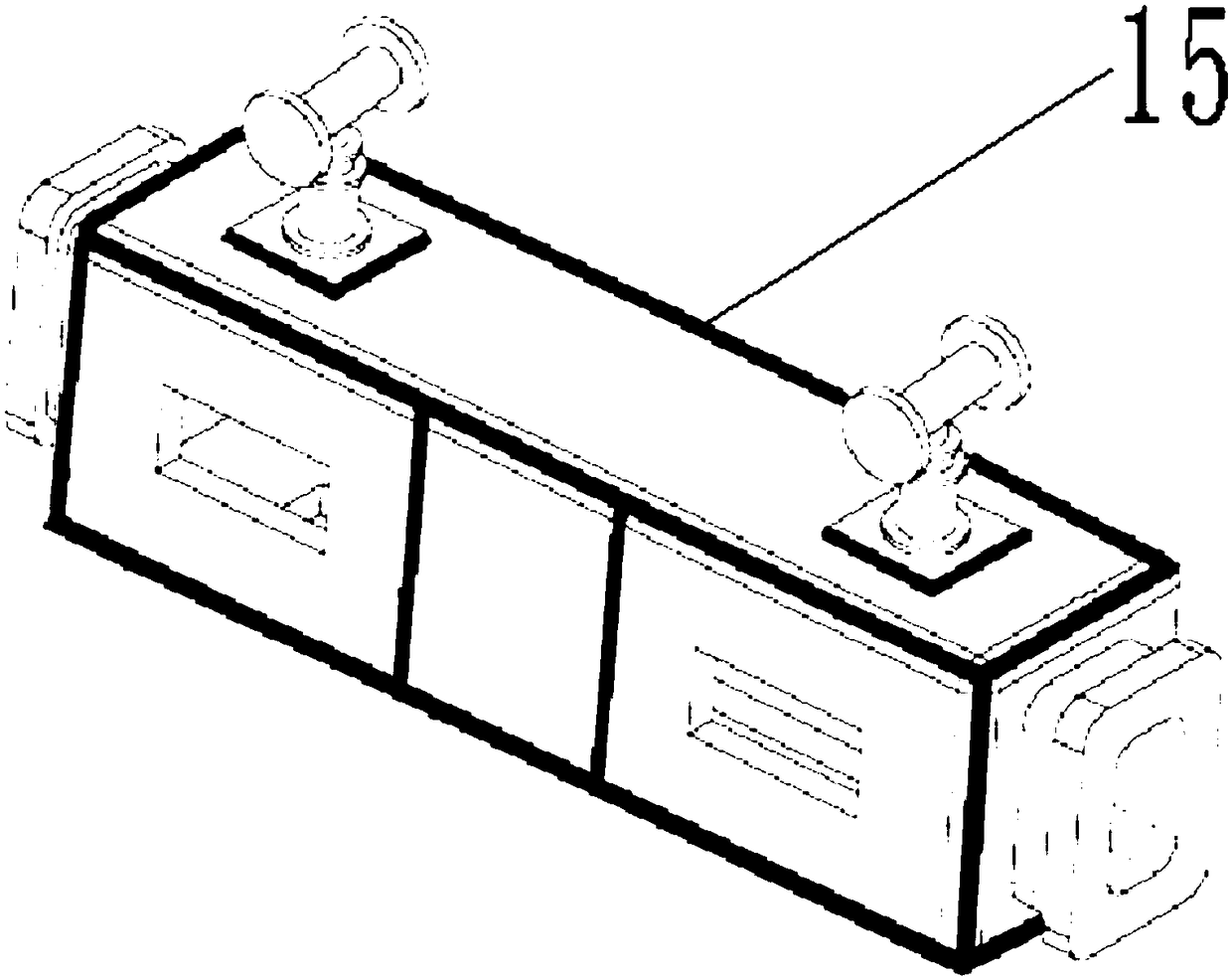

[0031] Such as Figure 1-6Shown, a kind of reinforced magnesium alloy suspended sky train car body and its manufacturing method, including train car body 1, roof 2, side wall 3, car door 4, sightseeing window 5, stiffening reinforcement material 6, Suspension steering mounting frame 7, inner preset structure 8, outer preset structure 9, end wall 10, roof suspension structure 11, car body edge 12, undercarriage 13, fixed door frame 14, rigid reinforcement structure 15 , connecting the bottom plate 16, the lower fixed shaft 17 and the upper suspension steering shaft 18, the train body 1 is a box-type structure welded by a magnesium alloy profile and a plate, and the train body 1 includes a roof 2, two The side wall 3, the two end walls 10 and the underframe 13, the roof 2, the two side walls 3, the two end walls 10 and the underframe 13 are respectively welded by magnesium alloy profiles, the roof 2. The upper parts of the two side walls 3 and the two end walls 10 are respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com