Green high-early-strength low-alkali liquid accelerator and preparation method thereof

An early-strength, accelerator technology, used in the field of building materials, can solve the problems of small market share, uncommon products, high price, and achieve the effects of reducing erosion, high later strength retention rate, and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

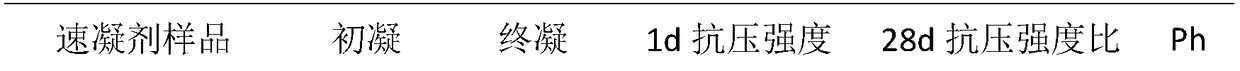

Examples

Embodiment 1

[0030] Aluminum sulfate (38%), sodium fluoride (15%), aluminum ethoxide (10%), triethanolamine maleate (8%), warm rubber (2%), polydimethylsiloxane (0.5 %), and the rest is water.

[0031] A preparation method of the above-mentioned sprayed concrete with low-alkali liquid quick-setting agent, comprising the following steps:

[0032] (1) Add water into the water bath container and heat to 60°C-70°C;

[0033] (2) Keep stirring, add sodium fluoride and aluminum alkoxide to water successively;

[0034] (3) Use a constant flow pump to slowly add the stabilizer, that is, the modified alcohol amine, and the dropping time is completed within 1h-1.5h;

[0035] (4) Keep the constant temperature state, add aluminum sulfate, and continue to stir until completely dissolved;

[0036] (5) Transfer the above solution to a laboratory high-speed shear emulsifier, add suspending agent and defoamer, start the high-speed shear emulsifier, adjust the speed to 3000-5000r / min, and emulsify for 0.5...

Embodiment 2

[0038] Aluminum Sulfate (45%), Sodium Fluoride (10%), Aluminum Isopropoxide (8%), Triethanolamine Maleate (6%), Warm Rubber (3%), Dimethicone (1%) and the rest is water.

[0039] The preparation method refers to Example 1.

Embodiment 3

[0041] Aluminum Sulfate (50%), Sodium Fluoride (10%), Aluminum Ethoxide (6%), Triethanolamine Acetate (4%), Xanthan Gum (2%), Dimethicone (0.5%) ), and the rest is water.

[0042] The preparation method refers to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com