High-strength high-impact weather-resistant polypropylene material for outdoor unit of air conditioner and preparation method of high-strength high-impact weather-resistant polypropylene material

A technology for weather-resistant polypropylene and air-conditioning outdoor units, which is applied in the field of polypropylene composite materials, can solve problems such as inability to meet the needs of air-conditioning outdoor unit shells, and achieve improved dispersion, excellent internal and external lubrication, and improved strength and modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

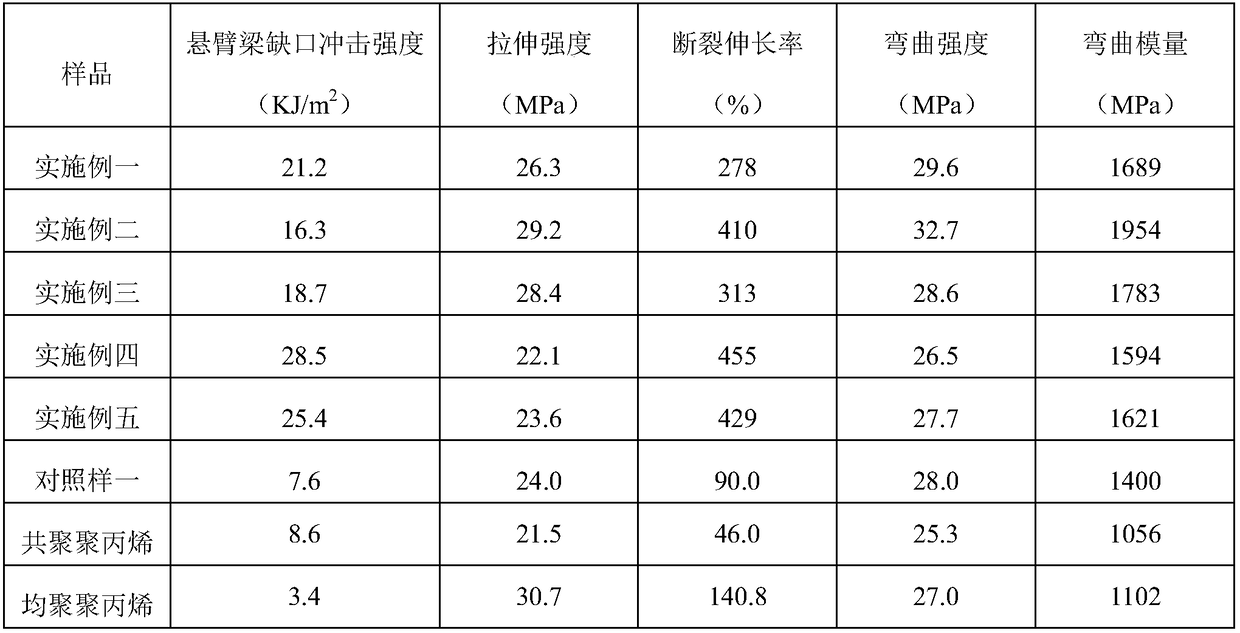

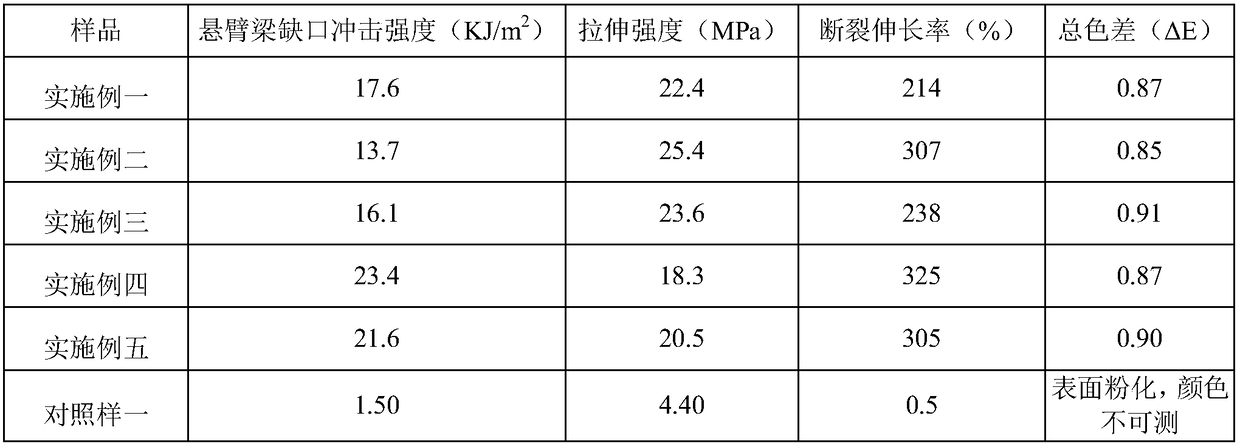

Examples

preparation example Construction

[0029] A method for preparing a high-strength high-impact weather-resistant polypropylene material for an air-conditioning outdoor unit of the present invention comprises the following steps:

[0030] 1) Take the copolymerized polypropylene and the homopolypropylene, mix them, add a coupling agent, mix them evenly, and get the mixed raw materials;

[0031] 2) Take POE, maleic anhydride grafted polypropylene, calcium carbonate, nucleating agent, antioxidant, dispersant and weathering agent, and mix them to form an additive package;

[0032] 3) Add the additive package obtained in step 2) to the mixed raw material obtained in step 1), mix evenly, and add it to the twin-screw extruder. -200℃, 3rd zone 190-210℃, 4th zone 190-210℃, 5th zone 200-220℃, 6th zone 200-220℃, 7th zone 200-220℃, 8th zone 200-215℃, 9th zone 200- 215°C, 210-230°C in the tenth zone, cooling, granulation, and polypropylene composite material.

Embodiment 1

[0034] A method for preparing a high-strength high-impact weather-resistant polypropylene material for an air-conditioning outdoor unit of the present invention comprises the following steps:

[0035] 1) Weigh the raw materials according to the following parts by weight: 55 parts of copolymerized polypropylene, 28 parts of homopolypropylene, 7 parts of POE, 2 parts of maleic anhydride grafted polypropylene, 10 parts of calcium carbonate, 0.3 parts of nucleating agent, antioxidant 0.3 part of agent 1010, 0.2 part of antioxidant ps802, 0.3 part of coupling agent, 1.0 part of dispersant, 0.2 part of weather resistance agent;

[0036] 2) Take copolymerized polypropylene and homopolypropylene, add them to a high-speed mixer for mixing, add a coupling agent for initial mixing, and mix evenly to obtain a mixed initial material;

[0037] 3) Take POE, maleic anhydride grafted polypropylene, calcium carbonate, nucleating agent, antioxidant, dispersant and weathering agent, and mix them ...

Embodiment 2

[0040] A method for preparing a high-strength high-impact weather-resistant polypropylene material for an air-conditioning outdoor unit of the present invention comprises the following steps:

[0041] 1) Weigh raw materials according to the following parts by weight: 55 parts of copolymerized polypropylene, 30 parts of homopolypropylene, 5 parts of POE with a melt index of 3g / 10min, 5 parts of maleic anhydride grafted polypropylene, after stearic acid modification 10 parts of 7000 mesh calcium carbonate, α nucleating agent and described β nucleating agent are 0.2 part of composite nucleating agent according to the weight ratio of 1:1 composition, 0.25 part of antioxidant 1010, 1680.2 part of antioxidant, coupling 0.3 part of agent, 1.0 part of dispersant, 0.2 part of weathering agent;

[0042] 2) Take copolymerized polypropylene and homopolypropylene, add them to a high-speed mixer for mixing, add a coupling agent for initial mixing, and mix evenly to obtain a mixed initial ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com