Composite material board impact positioning method based on rotary invariant subspace

A composite material plate, rotation invariant technology, applied in the direction of analyzing materials, using sonic/ultrasonic/infrasonic waves for material analysis, processing the response signals of detection, etc., to achieve the effect of saving computing time, fast positioning, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

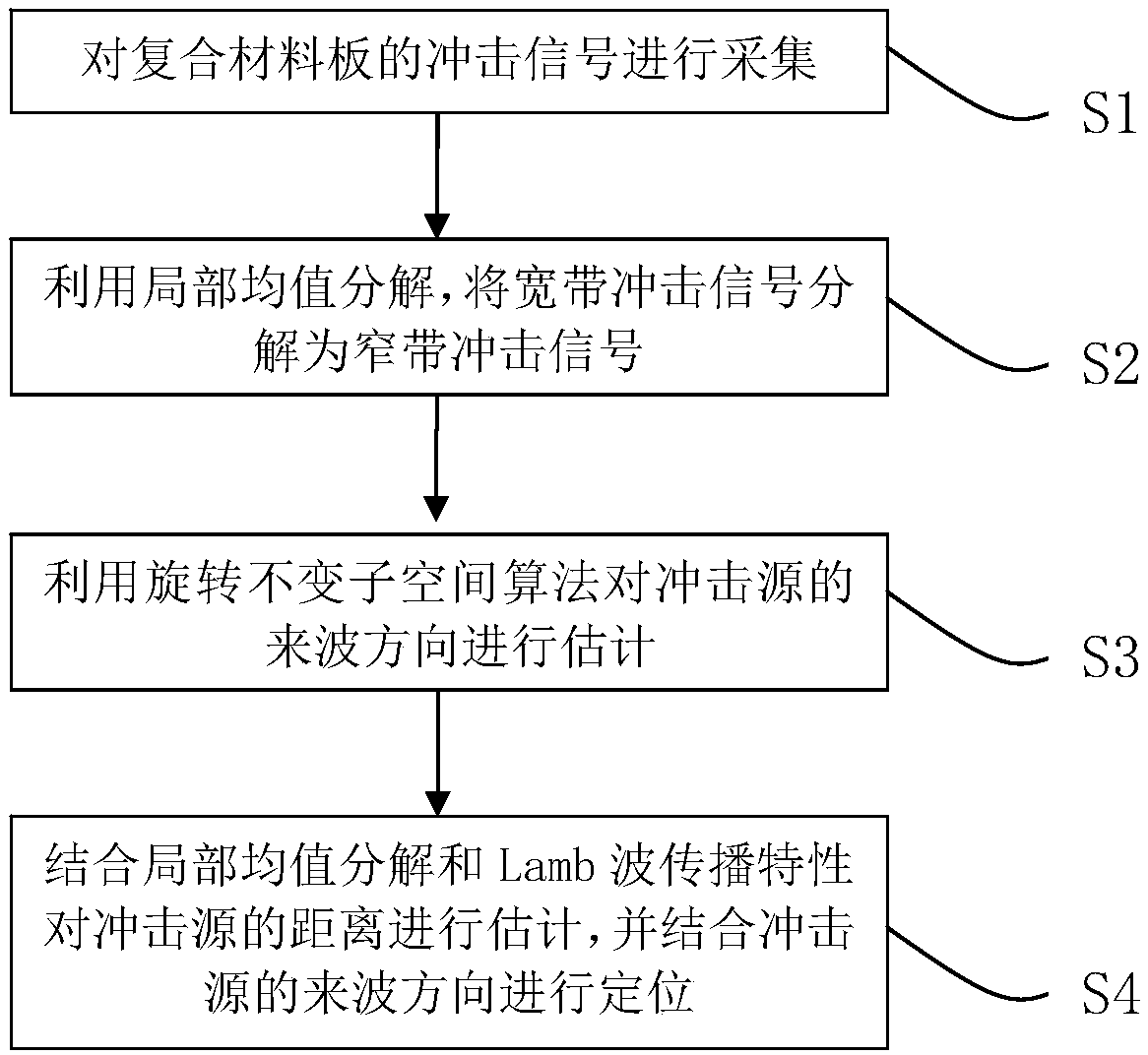

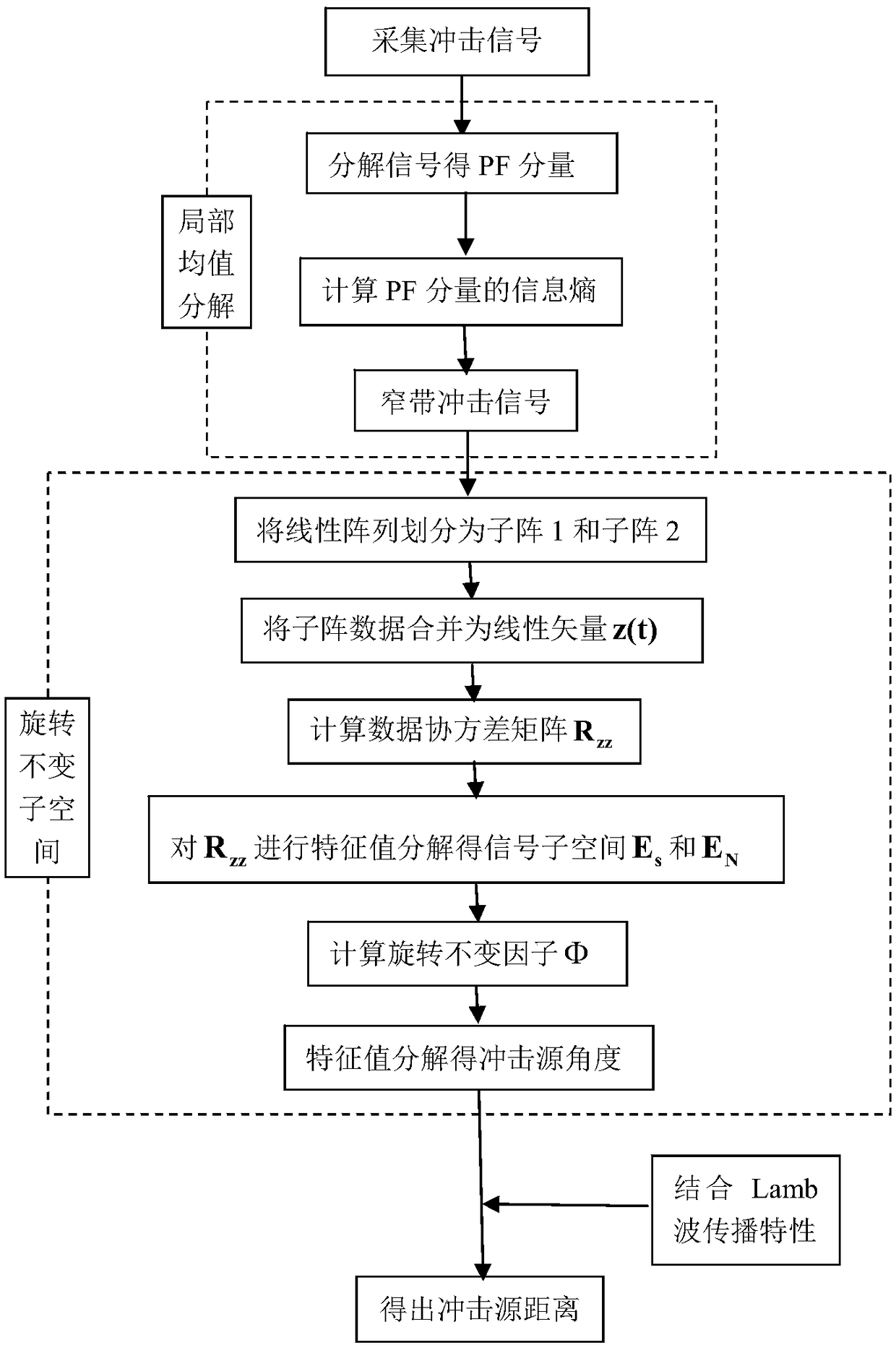

[0042] Such as figure 1 and figure 2 As shown, in the embodiment of the present invention, a method for impact positioning of a composite material plate based on a rotation invariant subspace is proposed, which includes the following steps:

[0043] S1. Collect the impact signal of the composite material plate. It mainly includes:

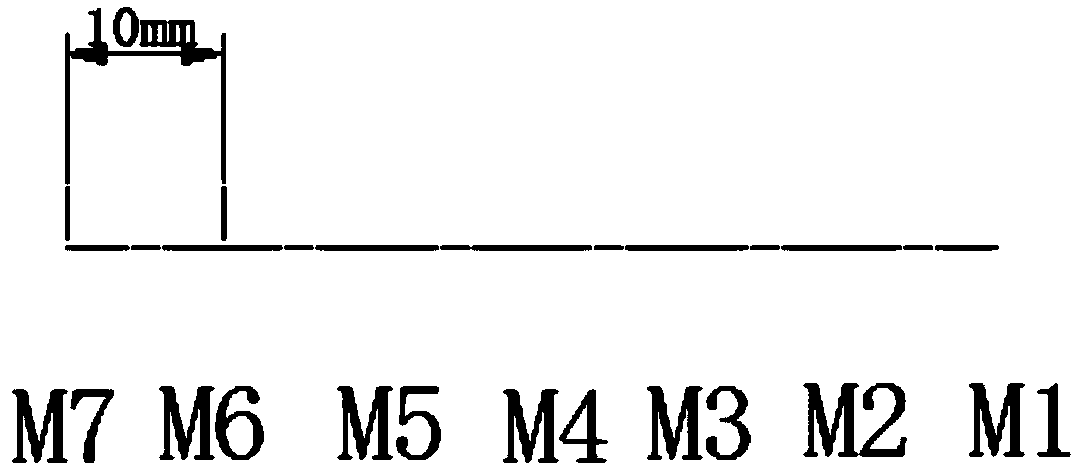

[0044] a) A plurality of piezoelectric ceramic sensors of the same type are arranged in an equidistant linear arrangement on the composite plate structure, and the distance between the sensors is set to 10mm to form a linear piezoelectric array;

[0045] b) Set the sampling parameters of the impact location monitoring system, set the sampling frequency to 5MHz, the sampling length to 8000, the pre-acquisition length to 1600, and the trigger threshold of the system to trigger the acquisition to 1V;

[0046] c) When the signal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com