Simulation method of opening position of energy release hole of explosion-proof device for high-voltage cable connector

An explosion-proof device, high-voltage cable technology, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve problems such as unfavorable waterproofing, optimization, complicated design, etc. The effect of improving the protection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

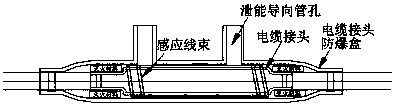

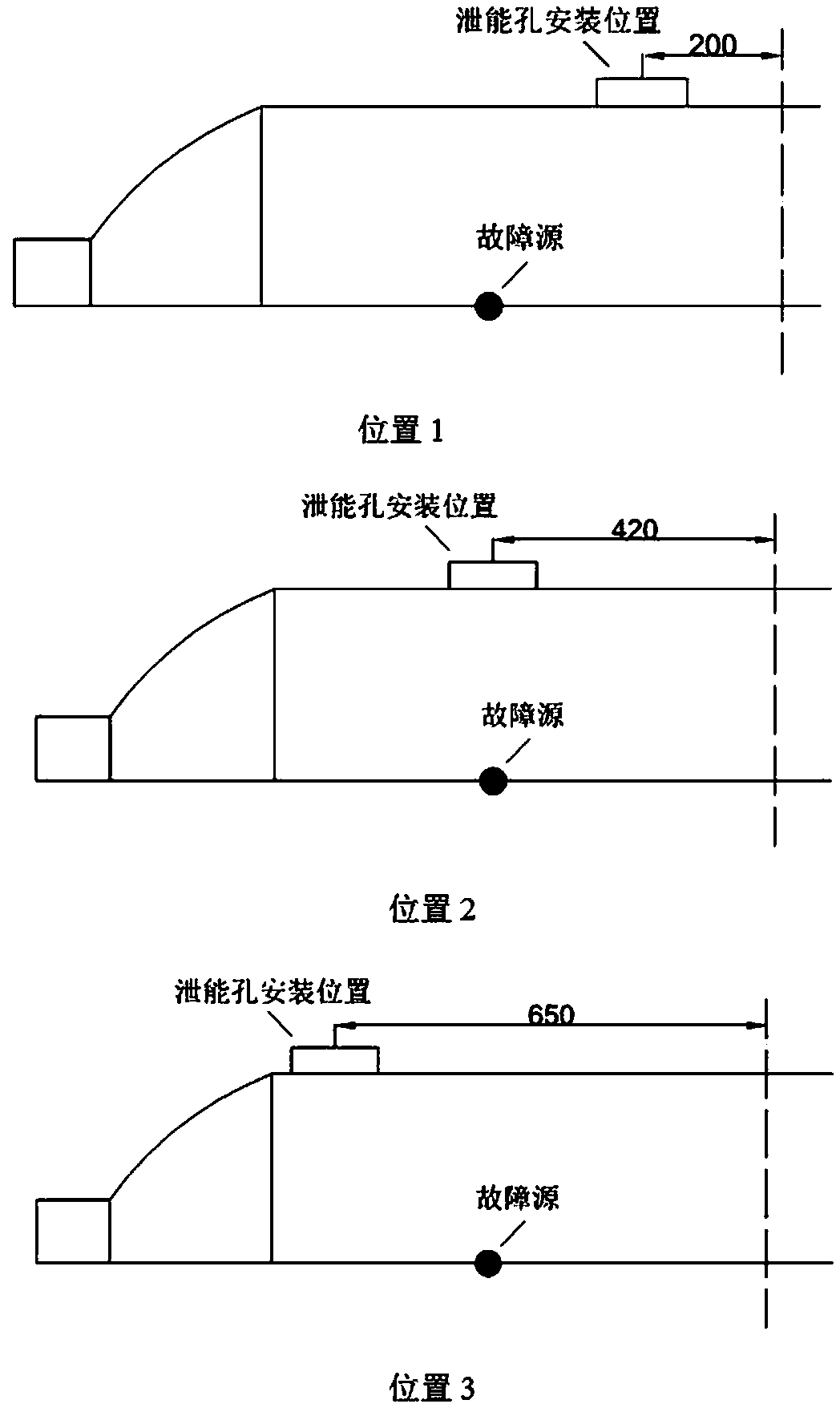

[0043] Such as Figure 2 to Figure 8 Shown is the embodiment of the simulation method of the opening position of the energy release hole of the high-voltage cable joint explosion-proof device of the present invention, comprising the following steps:

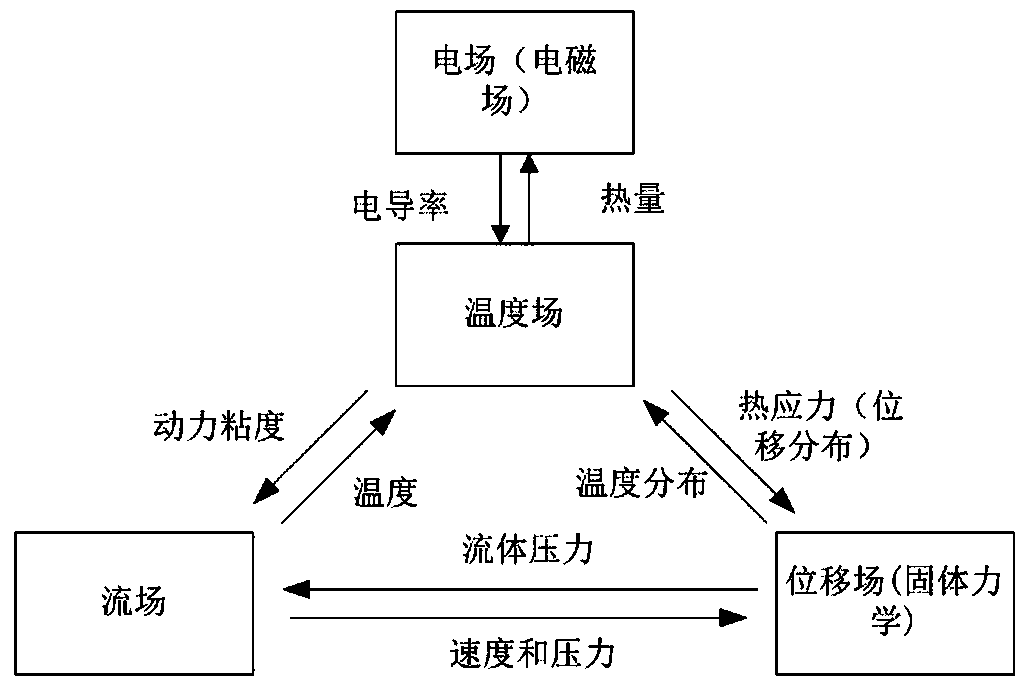

[0044]S1. According to the geometric parameters of each part of the accessories produced by the accessory manufacturer and the electric field strength of the material, establish a thermal-fluid-solid physical model of the high-voltage cable joint explosion-proof device;

[0045] S2. Coupling the thermal-fluid-solid physical model of the high-voltage cable joint explosion-proof device described in step S1 with multi-physics, and solving it by a multi-layer iterative algorithm;

[0046] S3. By simulating the internal airflow velocity and pressure distribution of the explosion-proof device at different time points, calculate the pressure release rate at the opening of the energy release hole at different installation positions;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com