Method for generating transition metal positive ion beam and device for method

A transition metal and metal ion technology, applied in accelerators, electrical components, etc., can solve the problems of limitation and high working temperature, and achieve the effect of reducing the extraction voltage, improving the use efficiency, and increasing the ion emission area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

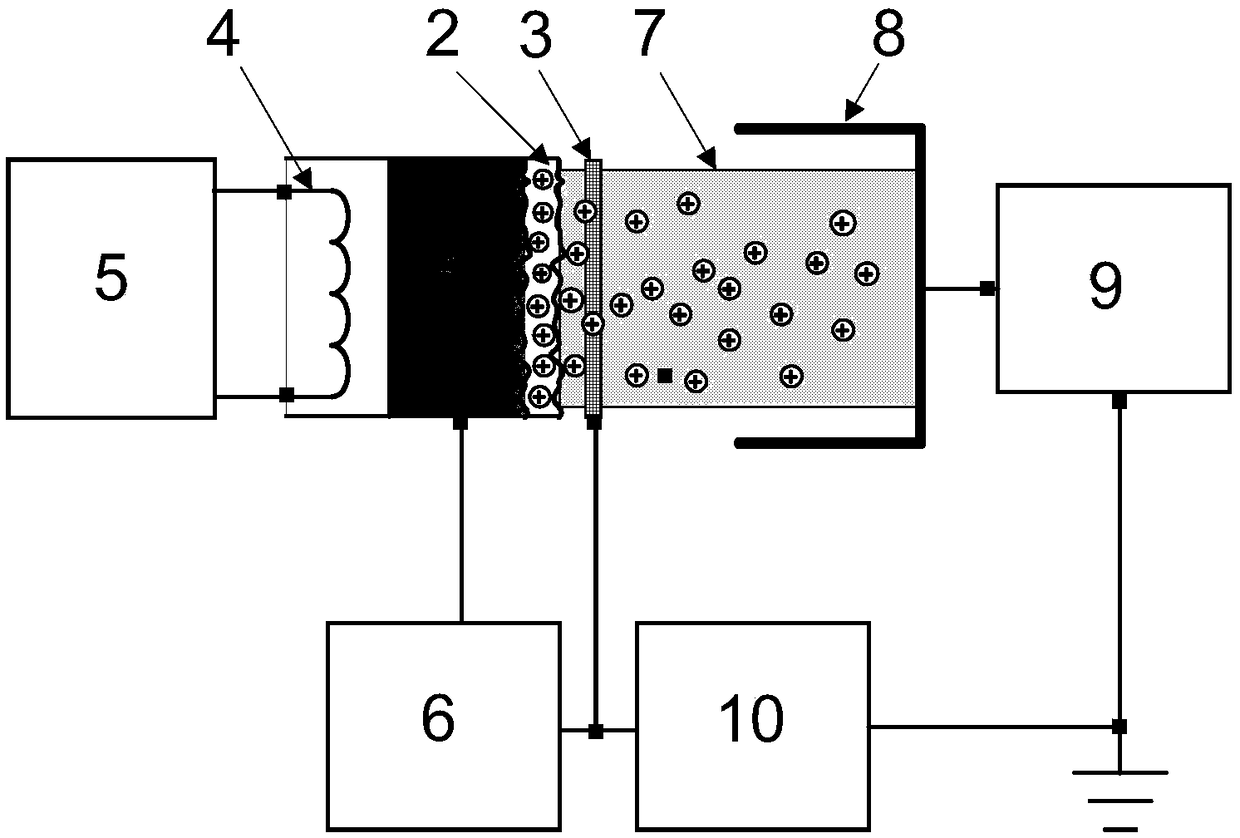

[0019] Describe below in conjunction with accompanying drawing and embodiment, a kind of method that produces transition metal positive ion beam and the device that is used for this method, device principle is as follows figure 1 As shown, the device as a whole is located at a vacuum degree of 10 -4 In the vacuum chamber of Pa, the anode of the drawn voltage is connected to the working substance reservoir, the working substance is a transition metal, and a high-purity silver cylinder or copper cylinder is used in the embodiment, and the positive surface of the working substance reservoir 1 of the cylinder is provided with Needle tips 11 arranged regularly or irregularly. The front surface of the working material reservoir is coated with a solid electrolyte film 2 with a thickness less than 1 micron, the solid electrolyte film is plated on the front surface of the cylindrical working material reservoir, and the solid electrolyte film is consistent with the micromorphology of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com