Double-sided grinding device

A double-sided grinding, double-sided technology, applied in the direction of grinding equipment, grinding machine tools, grinding tools, etc., can solve the problems of difficulty in adequate correspondence, deterioration of flatness, and increase in the amount of travel of the outer periphery of the wafer, and achieve the effect of improving the reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

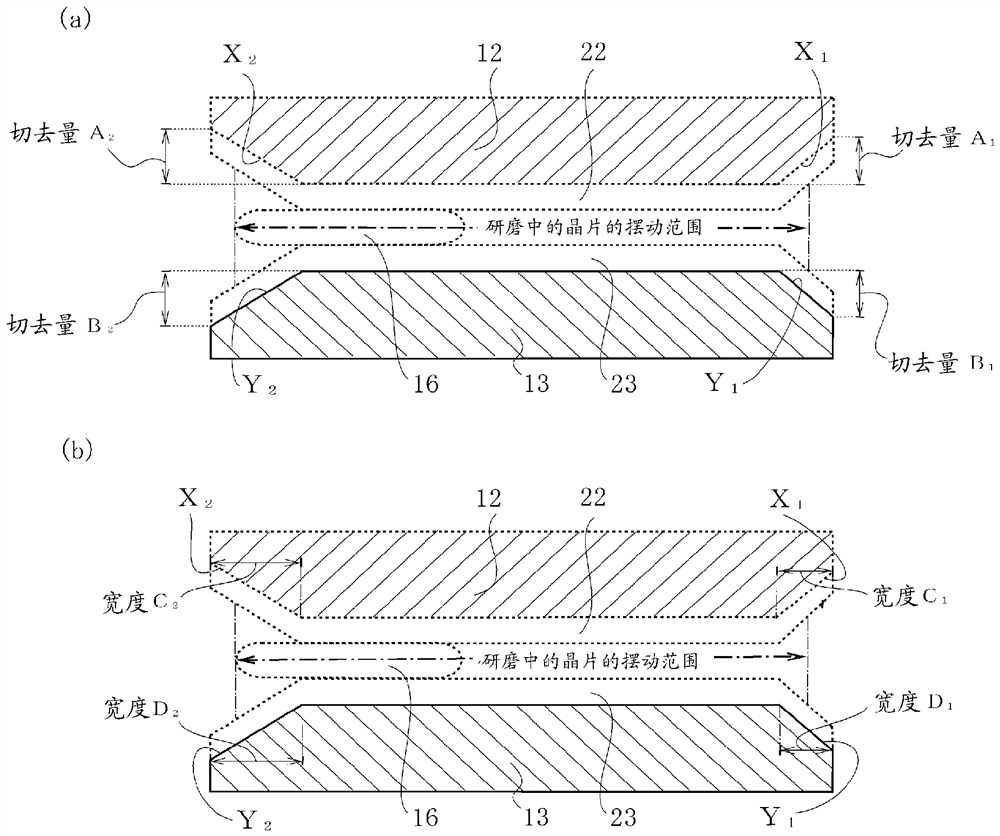

[0049] use figure 1 In the shown double-sided grinding device 10, the inner peripheral side is cut out X 1 , Y 1 The cut-off amount A in the vertical direction 1 , B 1 , Peripheral side cutting part X 2 , Y 2 The cut-off amount A in the vertical direction 2 , B 2 , Inner peripheral cutout part X 1 , Y 1 Each width of the horizontal direction C 1 、D 1 , Peripheral side cutting part X 2 , Y 2 The horizontal width C of 2 、D 2 The conditions of each test were changed as shown in Table 1 below, and both sides of the wafer were polished. Here, a silicon wafer with a diameter of 300 mm is used as the wafer. In each test case, A 1 =A 2 =B 1 =B 2 . Here, cut off part X on the inner peripheral side 1 , Y 1 Each width of the horizontal direction C 1 、D 1 , Peripheral side cutting part X 2 , Y 2 The horizontal width C of 2 、D 2 All are set to 51mm. In addition, the cut-out portion is formed by grinding each inner peripheral portion and each outer peripheral p...

Embodiment 2

[0059] use figure 1 In the shown double-sided grinding device 10, the inner peripheral side is cut out X 1 , Y 1 The horizontal width C of 1 、D 1 , Peripheral side cutting part X 2 , Y 2 The horizontal width C of 2 、D 2 The conditions of each test were changed, for example, as shown in Table 2 below, and both sides of the wafer were polished. Here, a silicon wafer with a diameter of 300 mm was used as the wafer. In addition, the coefficient α shown in Table 2 is the length of the cut-off portion with respect to the wafer diameter R, that is, by C 1 、C 2 、D 1 、D 2 =α×R represents the coefficient α. In addition, in each test example this time, C 1 =C 2 =D 1 =D 2 . In addition, the inner peripheral side cutout part X 1 , Y 1 The cut-off amount A in the vertical direction 1 , B 1 With the outer periphery side cutout part X 2 , Y 2 The cut-off amount A in the vertical direction 2 , B 2 In all Examples 1, it was fixed at 50 μm judged to be the optimum value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com