Wavelength Conversion Device and Laser Fluorescence Conversion Type Light Source

A wavelength conversion device and fluorescence technology, which is applied in the field of laser fluorescence conversion light source, can solve the problems of large heat generation, difficult application, low quantum efficiency of red phosphor powder, etc., achieve good shock resistance, improve light extraction efficiency, and reduce light loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

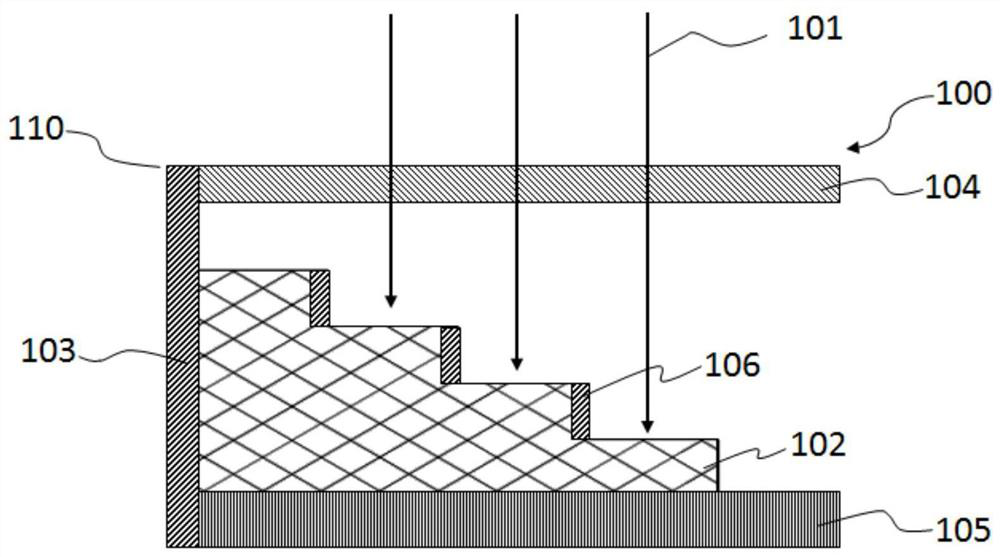

[0021] figure 1 A cross-sectional view of the wavelength conversion device 100 according to the first embodiment of the present invention is shown. The wavelength conversion device 100 includes a packaging component 110 and a fluorescent component 102 . Such as figure 1 As shown, the package assembly 110 is formed as a cuboid with a cavity inside, has four sides and a closed end surface 103 . Here, will figure 1 The horizontal direction in is called the length direction of the packaging component 110 and the fluorescent component 102, and the figure 1 The vertical direction in is called the thickness direction of the packaging component 110 and the fluorescent component 102, and the figure 1 The direction perpendicular to the paper surface in is referred to as the width direction of the packaging component 110 and the fluorescent component 102 . One of the four sides of the package assembly 110 ( figure 1 The upper surface in the middle) is used as a light incident end, ...

no. 2 example

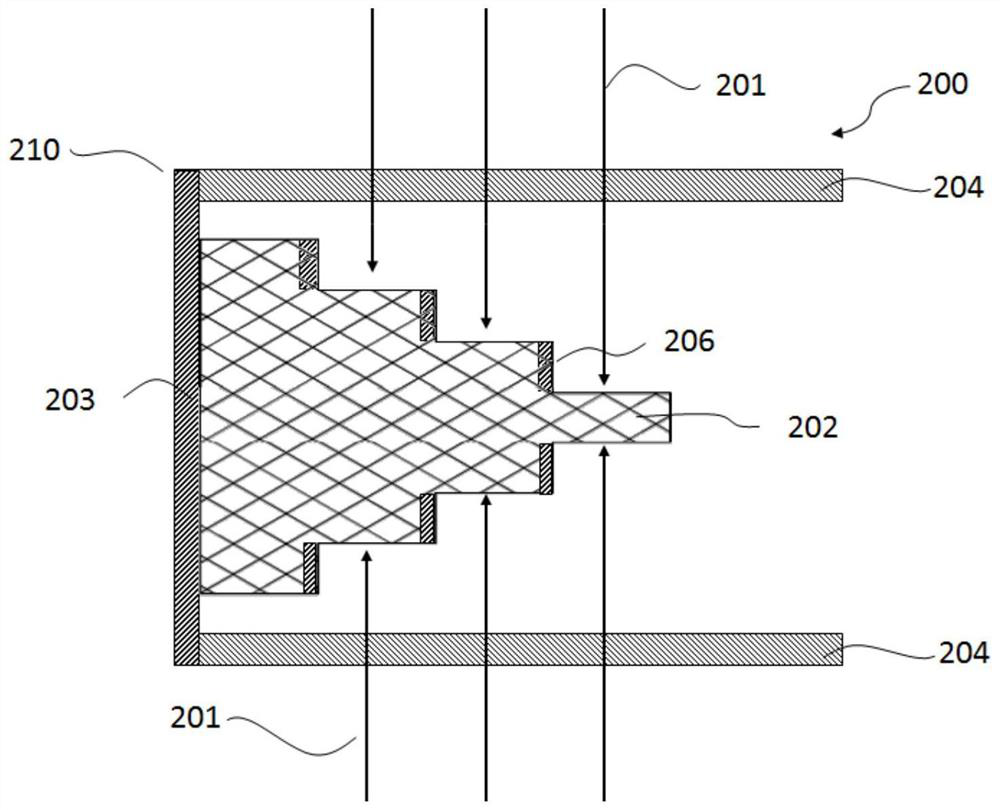

[0029] figure 2 A wavelength conversion device 200 according to a second embodiment of the present invention is illustrated. The wavelength conversion device 200 includes a package component 210 and a fluorescent component 202 , the package component 210 has a closed end face 203 . The wavelength conversion device 200 according to the second embodiment of the present invention is a modification of the above-mentioned wavelength conversion device 100, capable of receiving irradiation of opposite double-sided lasers. In the following description, a description of components of the wavelength conversion device 200 that are substantially the same as those of the wavelength conversion device 100 will be omitted.

[0030] The difference between the wavelength conversion device 200 and the wavelength conversion device 100 is that the two opposite sides of the packaging component 210 are respectively provided with incident light windows 204, the upper surface and the lower surface o...

no. 3 example

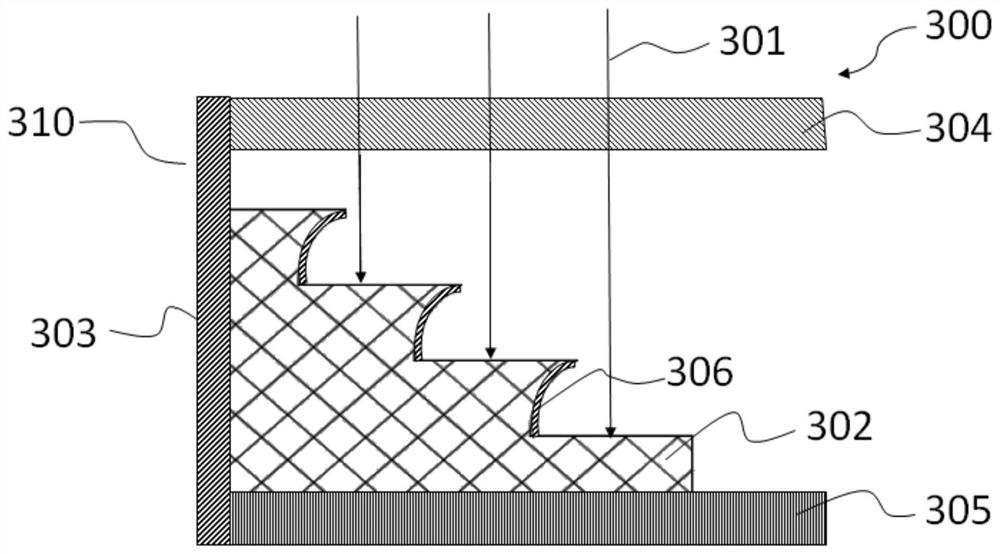

[0033] image 3 A wavelength conversion device 300 according to a third embodiment of the present invention is illustrated. The structure of the wavelength conversion device 300 is substantially the same as that of the wavelength conversion device 100 of the first embodiment. The wavelength conversion device 300 includes a packaging component 310 and a fluorescent component 302 . The package assembly 310 is formed as a cuboid having a cavity inside. The package assembly 310 has a closed end face 303, and an end opposite to the closed end face 303 is opened and serves as a light exit end. One surface ( image 3 The upper surface in the middle) is provided with an incident light window 304 . The surface of the fluorescent assembly 302 facing the incident light window 304 ( image 3 The middle is the upper surface) is formed into a stepped structure with multiple steps, the lower surface is bonded with a ceramic heat sink substrate 305, and one end surface of the fluorescent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com