Preservation of Bone Specimens by Using Vacuum Impregnation Technology

A vacuum impregnation and specimen technology, which is applied in the preservation, application, animal husbandry and other directions of human or animal body, can solve the problems of unsuitable protection of bone specimens, unsolved bone specimens, uneven paint film, etc., to achieve good protection effect, The effect of improving utilization and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

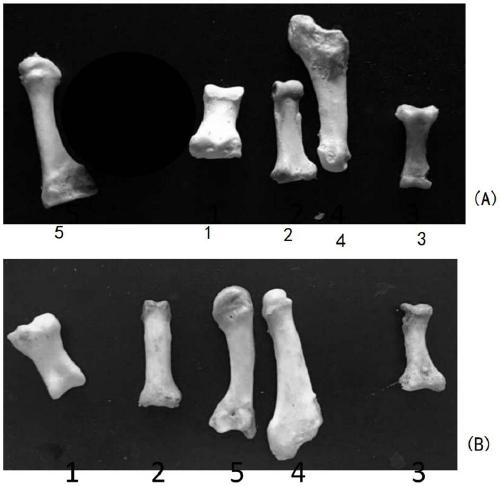

Embodiment 1

[0056] Prepare the bone samples before immersion and put them in an oven to fully dry for 20 minutes. The temperature is kept at about 100°C, so as to discharge the air and moisture in the bone as much as possible. At the same time, brush the container with simethicone to prevent the glue from sticking to the container. Mix HZ-806A and HZ-806B in a mass ratio of 3:1 to prepare a two-component epoxy epoxy working solution. Mix glycerol and ethanol at a volume ratio of 2:1 to prepare a protective solution, and place it in a sealed container to prevent moisture for later use.

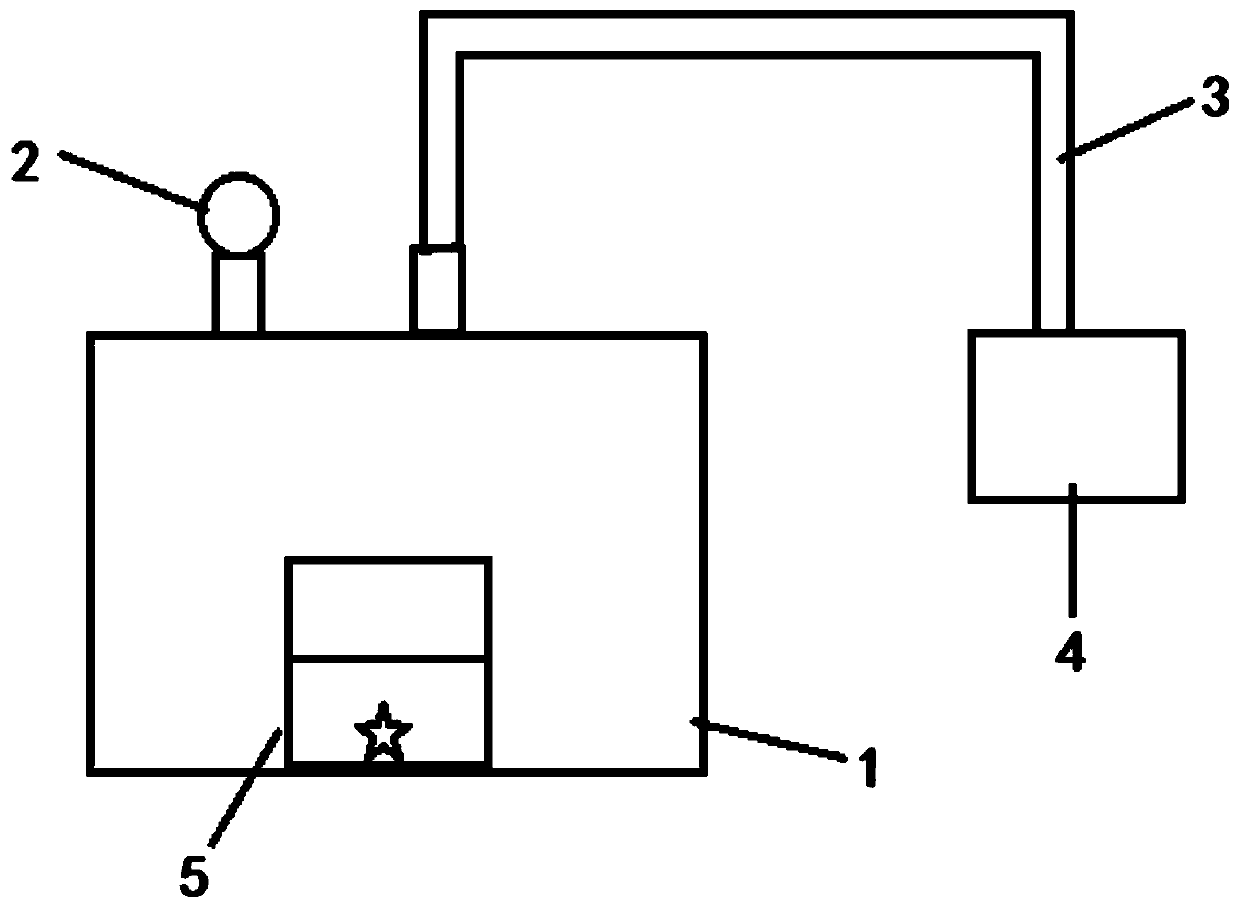

[0057] Vacuum impregnation and curing Take the sample out of the oven and immerse it in a container containing the prepared working solution while it is hot. For the long bones of the limbs, etc., make the working solution cover the bone end by about 1cm, and keep the backbone and the other end of the bone in the air. middle. Afterwards, the container is placed in the vacuum chamber, and the vacuum pump ...

Embodiment 2

[0060] Prepare the bone samples before immersion and put them in an oven to fully dry for 20 minutes. The temperature is kept at about 100°C, so as to discharge the air and moisture in the bone as much as possible. At the same time, brush the container with simethicone to prevent the glue from sticking to the container. Mix HZ-806A and HZ-806B in a mass ratio of 3:1 to prepare a two-component epoxy epoxy working solution. Mix glycerol and ethanol at a volume ratio of 2:1 to prepare a protective solution, and place it in a sealed container to prevent moisture for later use.

[0061] Vacuum impregnation and curing Take the sample out of the oven and immerse it in a container containing the prepared working solution while it is hot. For bones other than the long bones of the limbs, wrap them with wire mesh or gauze and completely immerse them in the working solution. Place the container in the vacuum chamber afterwards, turn on the vacuum pump, start timing after the air pressur...

Embodiment 3

[0063] Prepare the bone samples before immersion and put them in an oven to fully dry for 20 minutes. The temperature is kept at about 100°C, so as to discharge the air and moisture in the bone as much as possible. At the same time, brush the container with simethicone to prevent the glue from sticking to the container. Mix HZ-806A and HZ-806B in a mass ratio of 3:1 to prepare a two-component epoxy epoxy working solution. Mix glycerol and ethanol at a volume ratio of 2:1 to prepare a protective solution, and place it in a sealed container to prevent moisture for later use.

[0064] Vacuum impregnation and curing Take the sample out of the oven and immerse it in a container containing the prepared working solution while it is hot. For the long bones of the limbs, etc., make the working solution cover the bone end by about 1cm, and keep the backbone and the other end of the bone in the air. middle. Afterwards, the container is placed in the vacuum chamber, and the vacuum pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com