Dough mixer device for food processing

A technology of food processing and dough mixer, which is applied in the direction of dough mixer, mixing/kneading with vertical installation tools, application, etc., which can solve the problems of low production efficiency, potential safety hazards, waste of energy, etc., to save energy and improve safety Sexuality and convenient transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

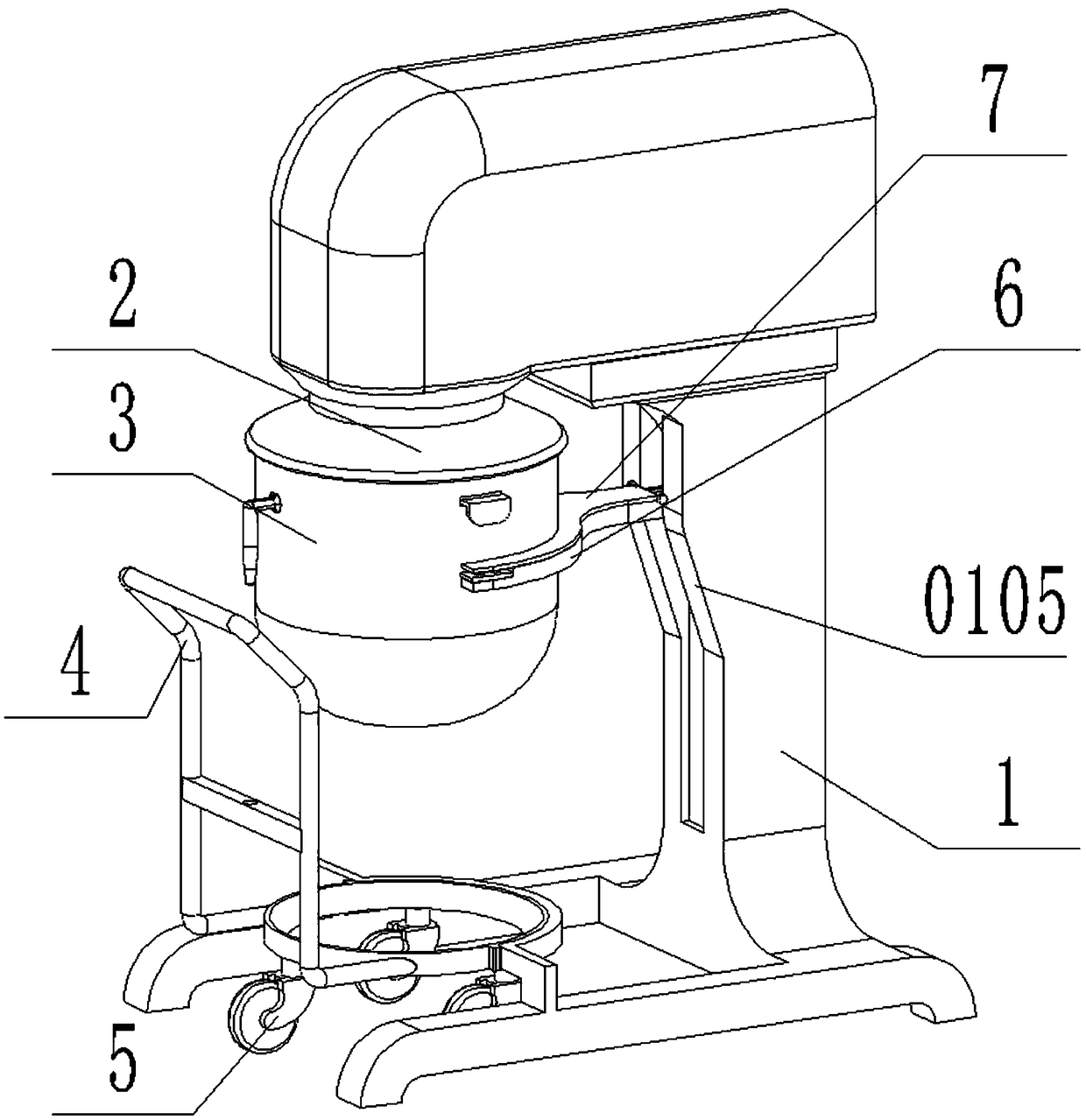

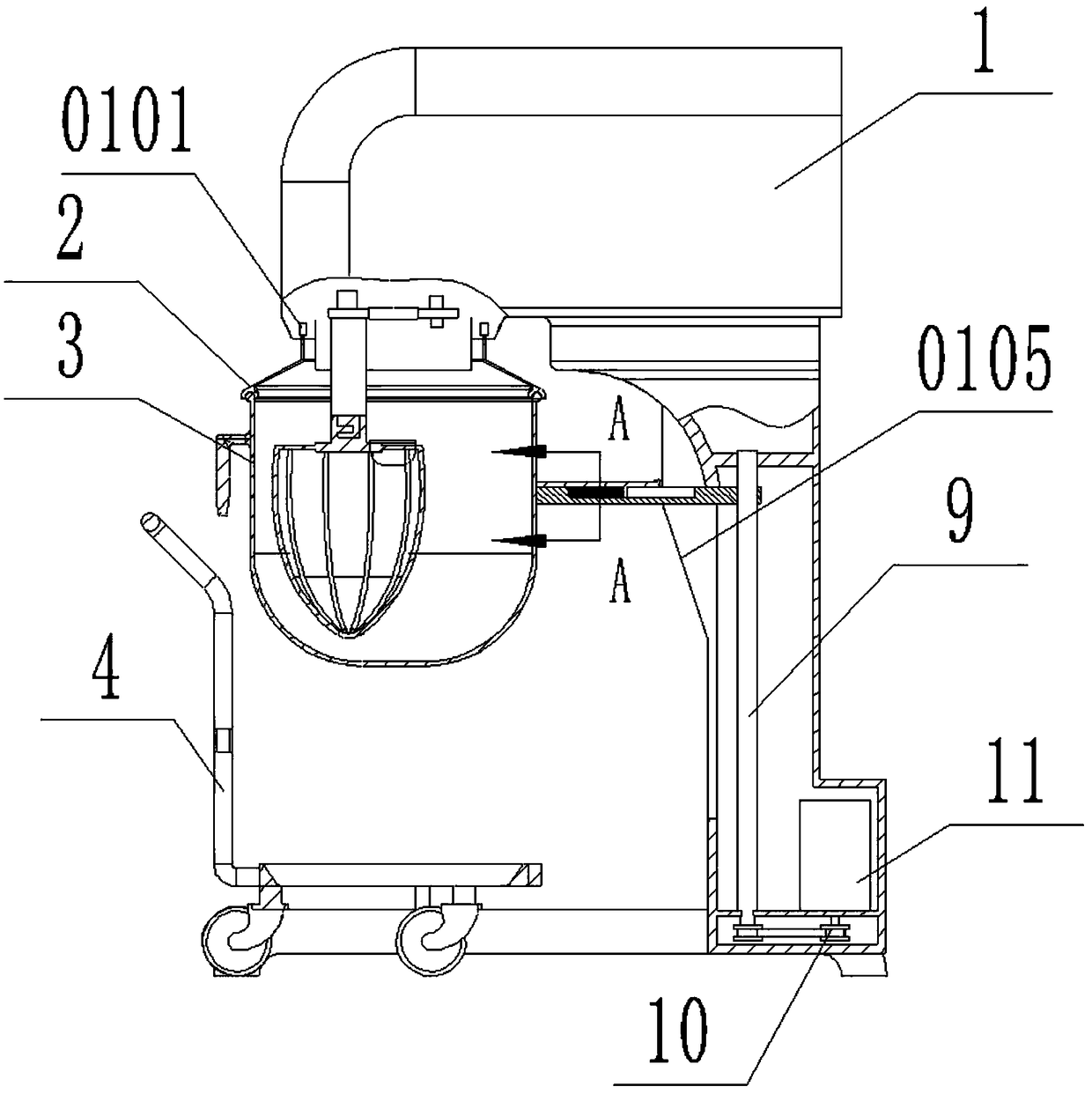

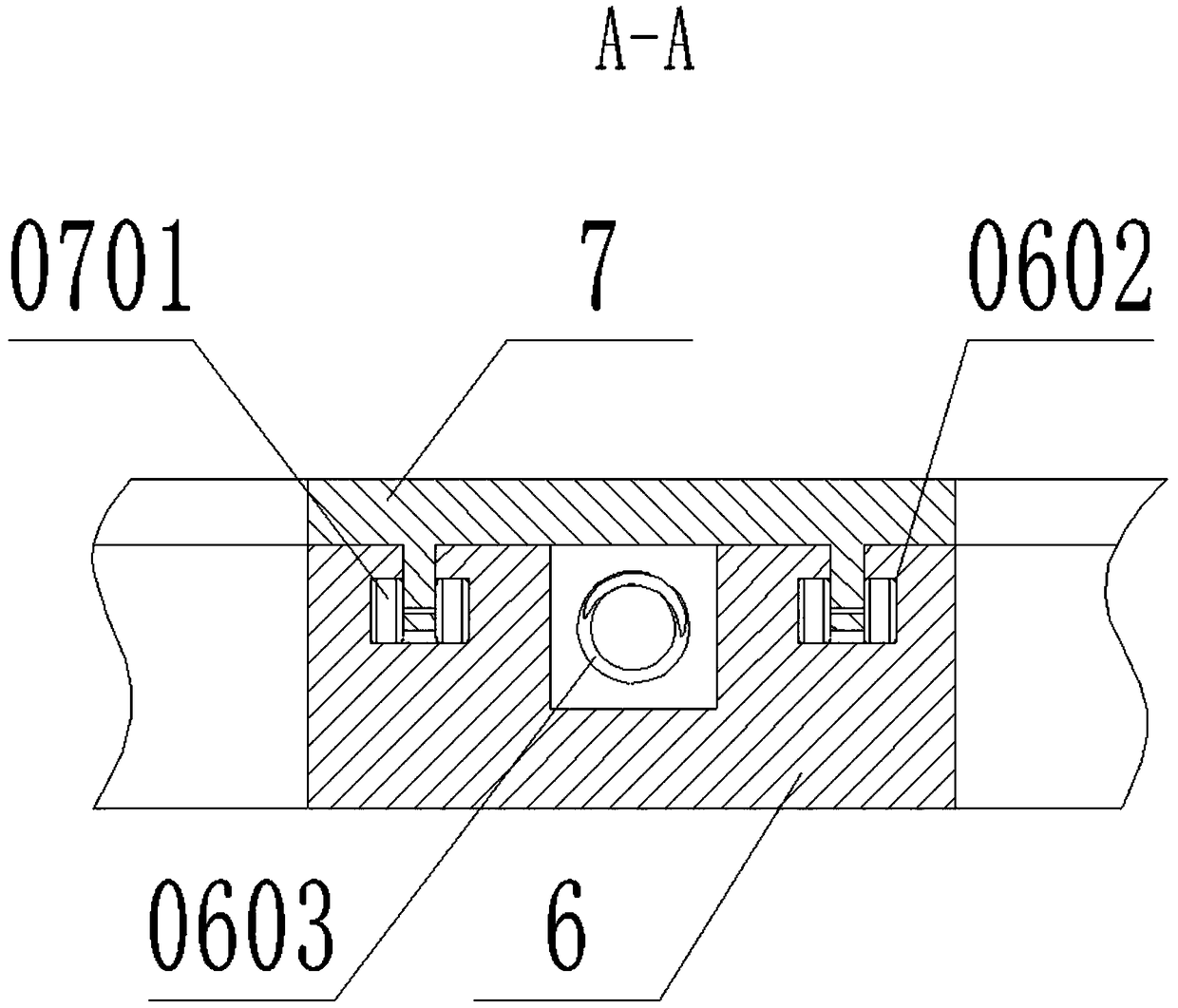

[0031] As attached figure 1 Attached Figure 8 Shown:

[0032] The present invention provides a kneading machine device for food processing, including: kneading machine main body 1, travel switch 0101, cart positioning plate 0102, plane positioning plate 0103, auxiliary magnet 0104, guide wheel guide surface 0105, and protective cover 2. Mixing barrel 3, handle 0301, fixed plate 0302, positioning hole 0303, transfer cart 4, handle socket 0401, cart positioning block 0402, universal wheel 5, support plate 6, positioning pin 0601, sliding groove 0602 Spring 0603, locking plate 7, sliding wheel 0701, guide wheel 8, screw nut transmission mechanism 9, belt transmission mechanism 10, and lifting motor 11; a set of lifting motors 11 is fixedly connected to the inner bottom of the right side of the dough machine main body 1; motor 11 A set of screw nut transmission mechanism 9 is connected to the shaft through the belt transmission mechanism 10; the screw nut transmission mechanism 9 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com