A kind of preparation method of cds/coo nano-heterostructure

A nano-heterostructure and nano-rod technology, applied in the direction of catalyst activation/preparation, nanotechnology, nanotechnology, etc., can solve the problems of high cost and low conversion rate of catalyst to solar energy, so as to reduce reaction cost and increase conversion utilization rate , good reusability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0048] Specific embodiment 1: In this embodiment, a method for preparing a CdS / CoO nano-heterostructure is carried out according to the following steps:

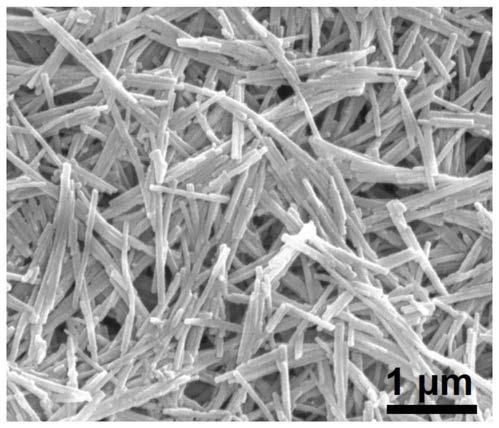

[0049] 1. The Cd(NO 3 ) 2 4H 2 O and NH 2 CSNH 2 Put it into the ethylenediamine solution and perform ultrasonic treatment. After the solution becomes clear, put it into a polytetrafluoroethylene reactor for hydrothermal reaction; then cool it to room temperature, then wash it with deionized water and absolute ethanol, and dry it. Obtain CdS nanorods;

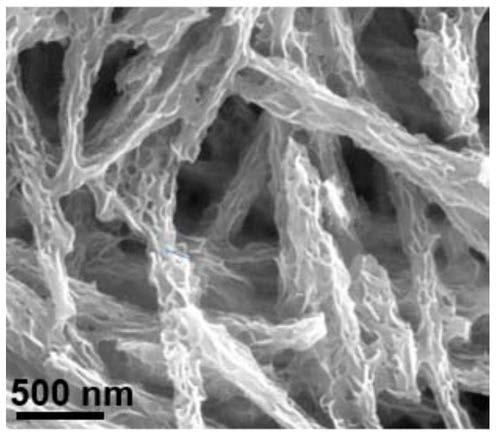

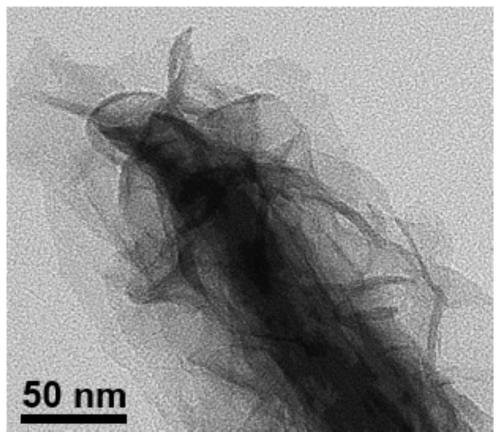

[0050] 2. Put the CdS nanorods obtained in step 1 into the methanol solution containing dimethylimidazole, and after the ultrasonic dispersion is uniform, add the 3 ) 2 methanol solution, stirred, and then centrifuged with methanol to obtain CdS / Co(OH) 2 nanocomposites;

[0051] 3. The CdS / Co(OH) obtained in step 2 2 The nano-composite material is calcined under an argon atmosphere to obtain the CdS / CoO nano-heterostructure.

specific Embodiment approach 2

[0052] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, Cd(NO 3 ) 2 4H 2 O, NH 2 CSNH 2 The mass volume ratio of the solution to ethylenediamine is (1-2) g: (1-2) g: (30-50) mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0053] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: the hydrothermal temperature in step 1 is 160-180° C., and the hydrothermal time is 24-48 hours. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com