Stone paper coating process and device

A technology of coating process and coating equipment, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., and can solve the problem of pull-off, poor bonding between coating and stone paper base paper, and lack of paper fibers Adhesion and other problems, to achieve the effect of high exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

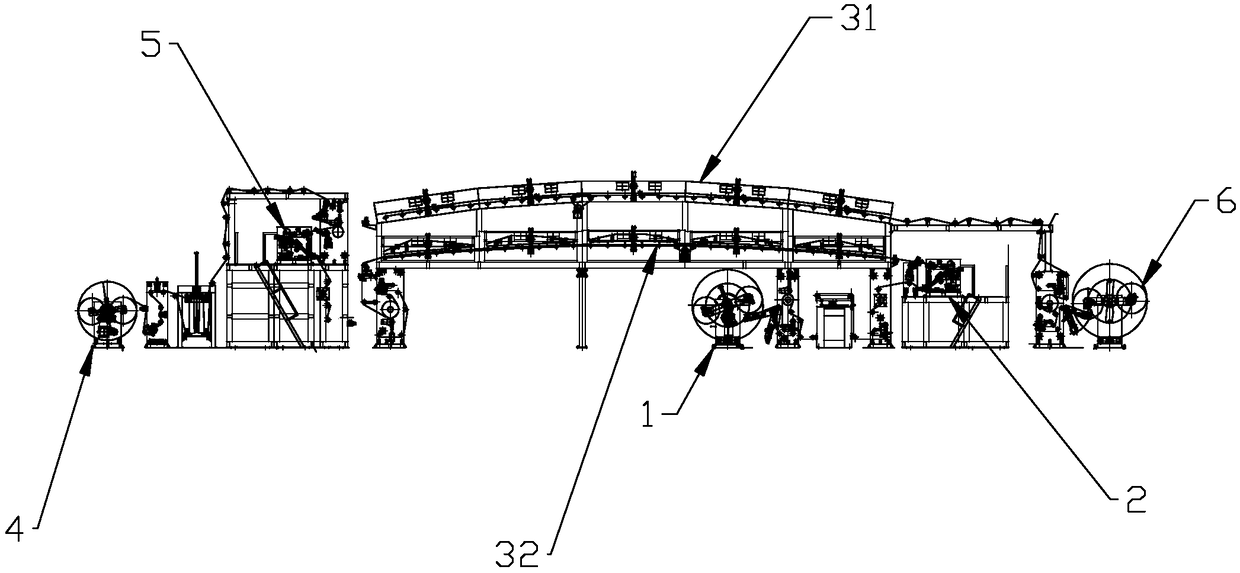

[0034] Such as figure 1 As shown, a stone-based paper coating process includes the following steps:

[0035] S1. Unwind the rock paper and apply external force to the paper to control the tension of the paper;

[0036] S2. Input the heated oil or water into the pressure roller contacting the paper to preheat the paper in indirect contact;

[0037] S3. Perform corona treatment on the first coated surface of the paper;

[0038] S4. Eliminate static electricity on the paper, and then evenly apply the coating liquid to the first coating surface of the paper;

[0039] S5. Dry the first coated surface of the paper;

[0040] S6. Cooling the dried paper through indirect contact and cooling to the preheating temperature by inputting the cooling liquid into the pressure roller in contact with the paper;

[0041] S7. Reverse the paper orientation and corona treatment on the second coated surface of the paper;

[0042] S8. Eliminate static electricity on the paper, and then evenly apply the coating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com