Multi-energy beam high-efficiency additive manufacturing method

An additive manufacturing and high-efficiency technology, which is applied in the field of multi-energy beam high-efficiency additive manufacturing, can solve the problems of no improvement in the forming efficiency of a single format, the inability to realize multiple scanning strategies, and reduce the overall forming efficiency. High phenomenon, improve the forming internal stress, improve the effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Design of multi-set galvanometer optical path system with full energy beam coverage

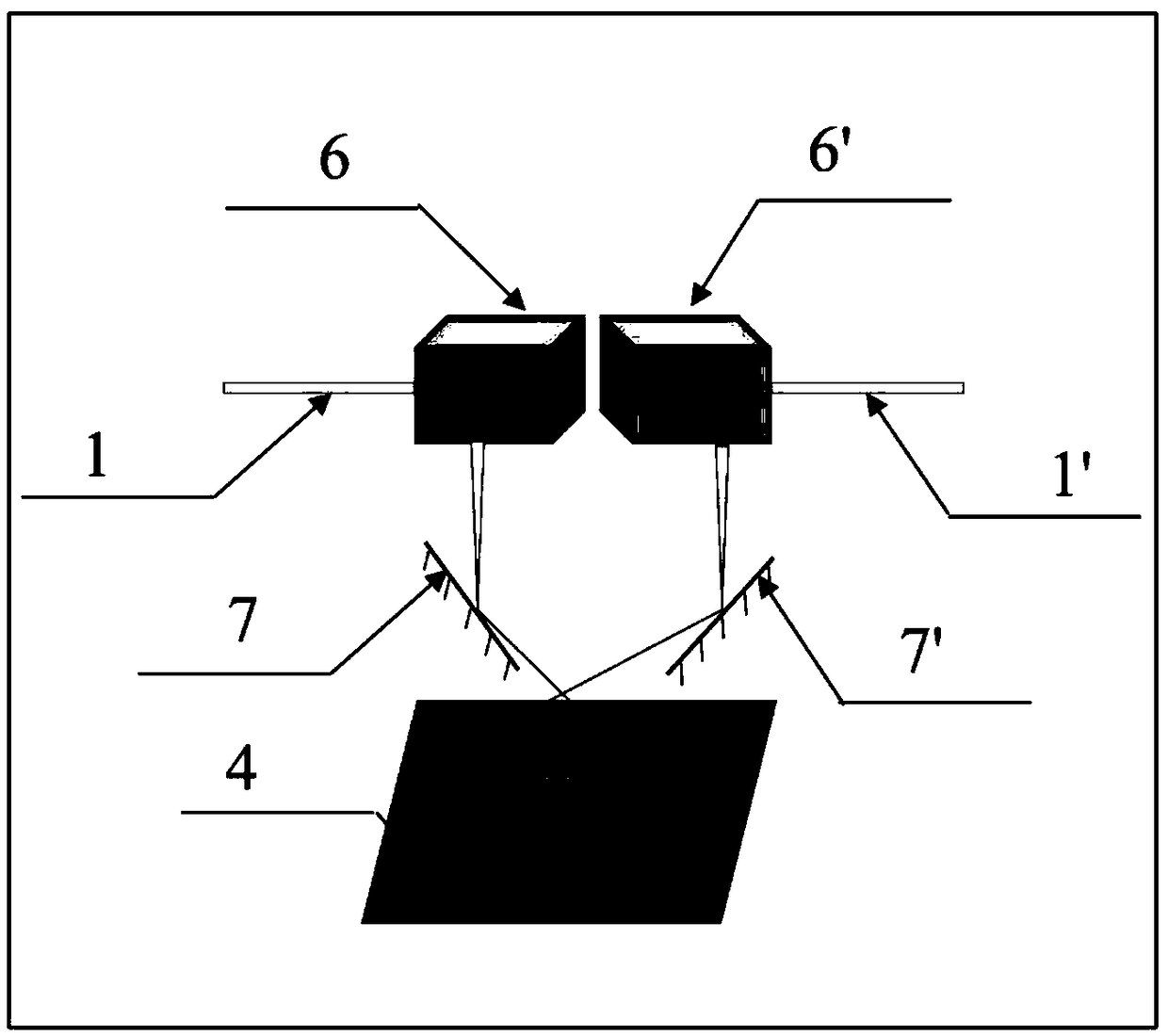

[0033] Such as figure 2 As shown, in this example, two laser beams 1 and 1', two galvanometer systems 6 and 6', and two reflectors 7 and 7' are used to realize the scanning mode in which the energy beams can cover the whole frame.

[0034] The working principle of the optical path system is that two beams of light 1 and 1' respectively enter the respective galvanometer systems 6 and 6' from the side, and emit beams from the bottom of the galvanometer.

[0035] The light beams emitted from the bottom of the galvanometer pass through the reflectors 7 and 7' respectively, and finally directly irradiate the entire forming area.

[0036] The light beam mainly realizes the direction change of the incident beam through the vibrating mirror and the reflecting mirror, and the rotation of the reflecting mirror and the organic combination of the vibrating mirror further expand the co...

example 2

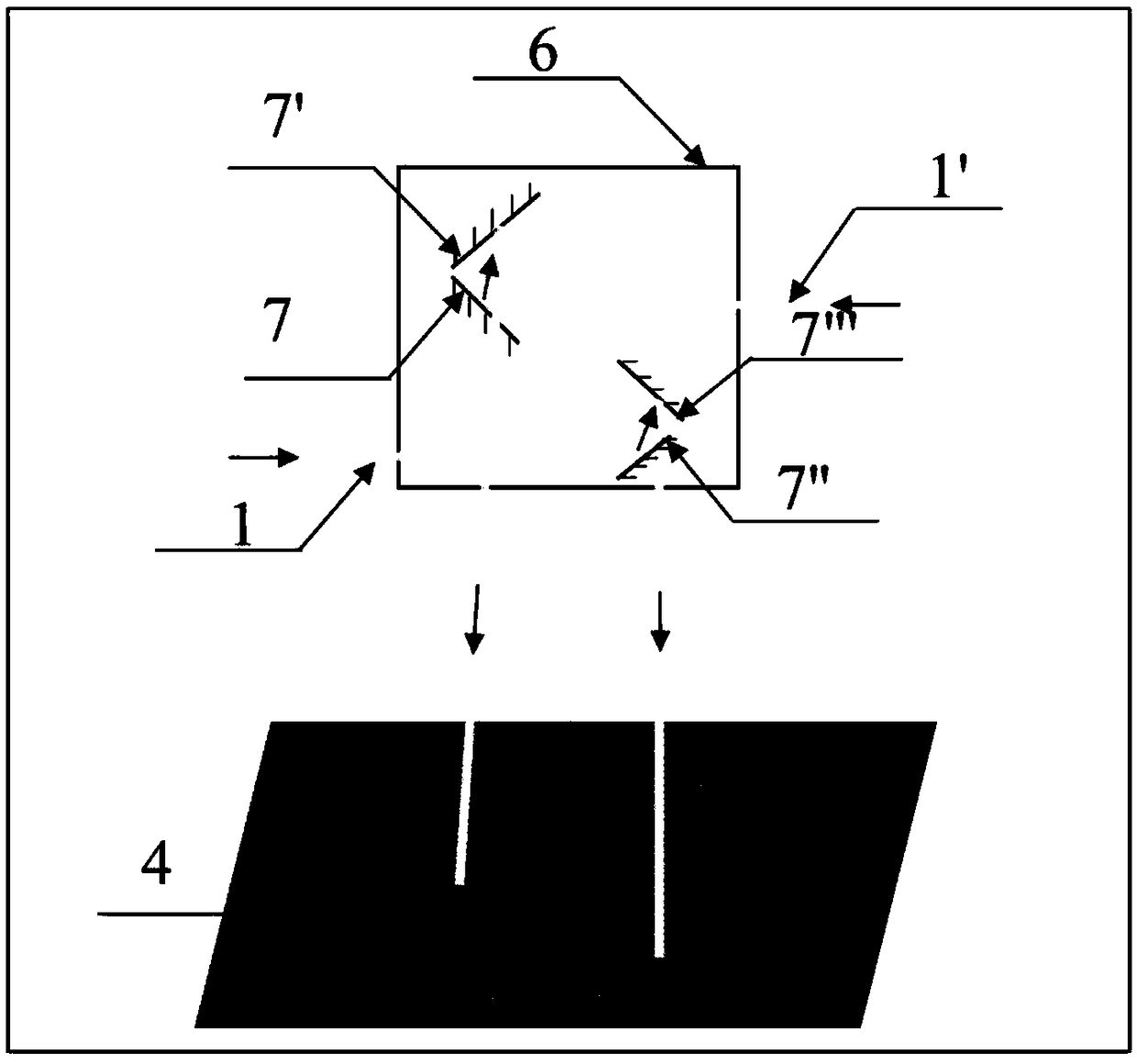

[0037] Example 2: Design of a galvanometer optical path system with full coverage of the energy beam II

[0038] Such as image 3 As shown, this example designs a new type of galvanometer optical path system, so that each energy beam can irradiate the entire forming area.

[0039] The vibrating mirror system includes a vibrating mirror 6, and two sets of reflecting mirrors (7 and 7', 7" and 7'") are integrated.

[0040] Two sets of reflective mirrors are respectively located at the upper part and the lower part of the vibrating mirror system, and two laser beams 1 and 1' are respectively injected into the vibrating mirror system from both sides.

[0041] After passing through the corresponding reflector lens groups respectively, through the rotation of the reflector and the organic mutual cooperation, the two beams of light are emitted from the bottom of the vibrating mirror.

[0042] Based on the existing vibrating mirror system, this design method adopts two sets of reflec...

example 3

[0043] Example 3: Powder-spreading multi-laser beam interval scanning

[0044] Such as Figure 4 As shown, in this example, two laser beams are used for rapid processing of the component at the same time, and the powder supply method adopts the powder spreading method.

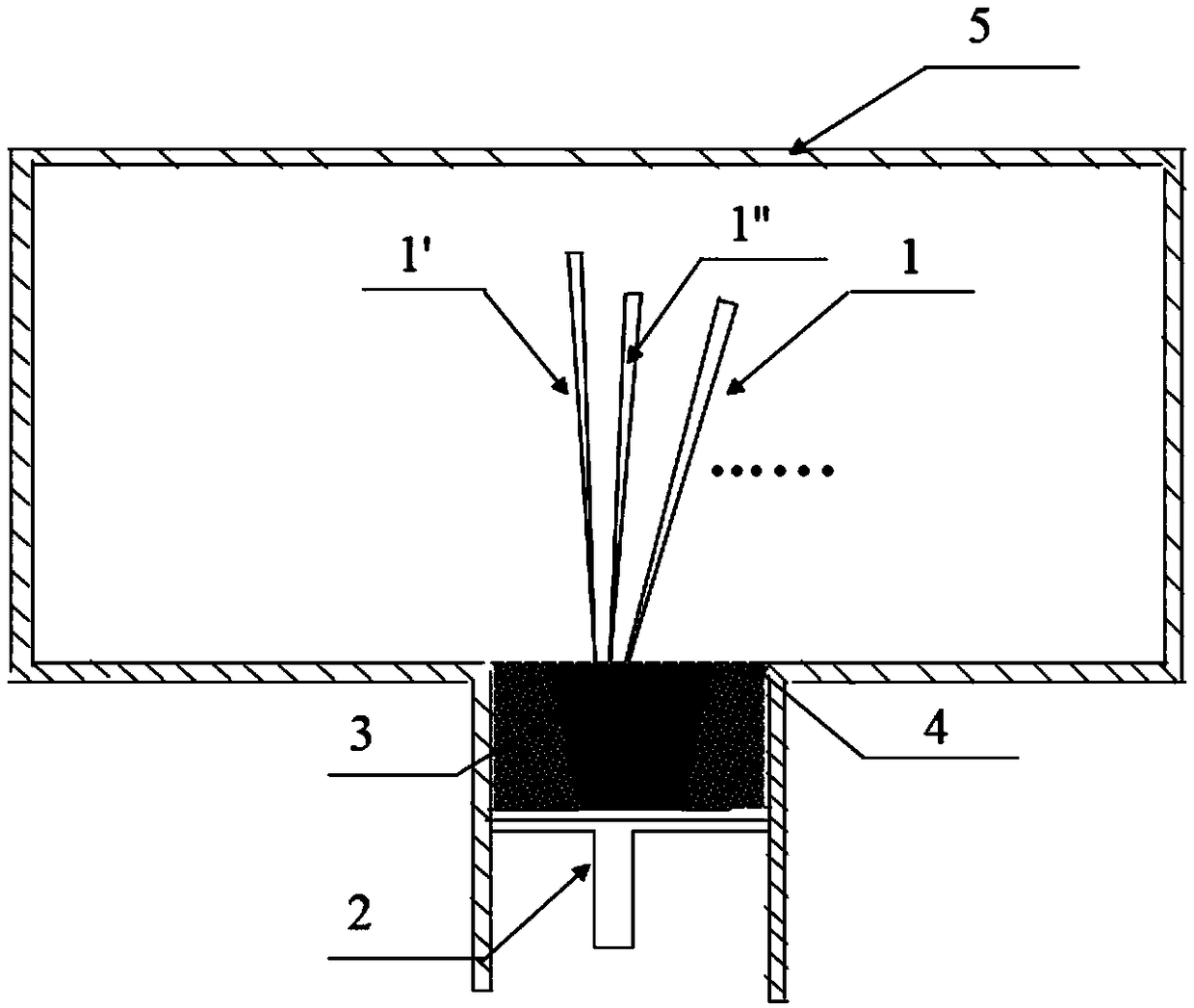

[0045] Before the two laser beams are processed, the protective gas is passed into the forming cavity 5 to reduce the oxygen content in the forming area, so as to ensure the quality of the forming and the safety of the processing process.

[0046] On the surface of the working platform 4, the laser beams 1 and 1' first scan and process the adjacent tracks of the current layer, and after scanning the corresponding single track, the corresponding laser beams 1 and 1' scan and process the other two tracks at the same time , until the current layer is completely scanned by the energy beam.

[0047] The 2 laser beams work independently without affecting each other until the current layer is completely melted.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com