Plastic welding machine control system, equipment and method

A control system and welding machine technology, applied in general control systems, control/adjustment systems, computer control, etc., can solve the problems of manual switching of voltage, unfriendly user experience, and low level of automation, etc., to improve user experience , enhance automation and intelligence, and improve the effect of plastic welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

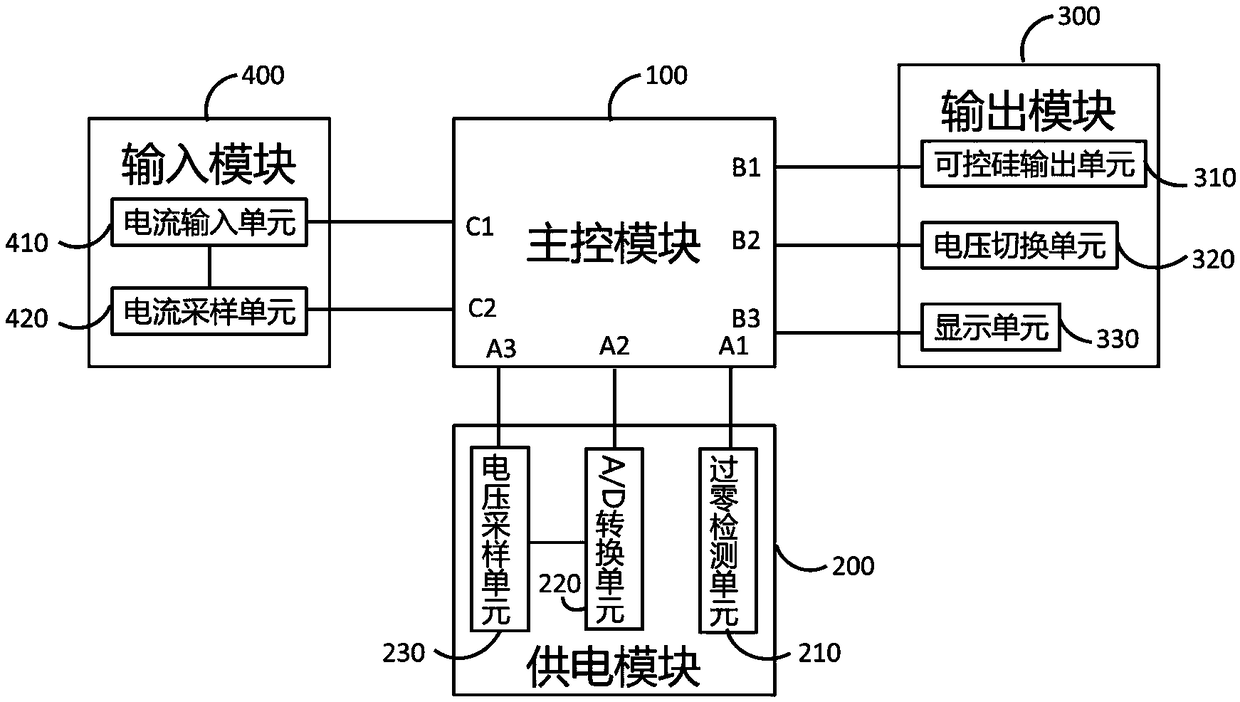

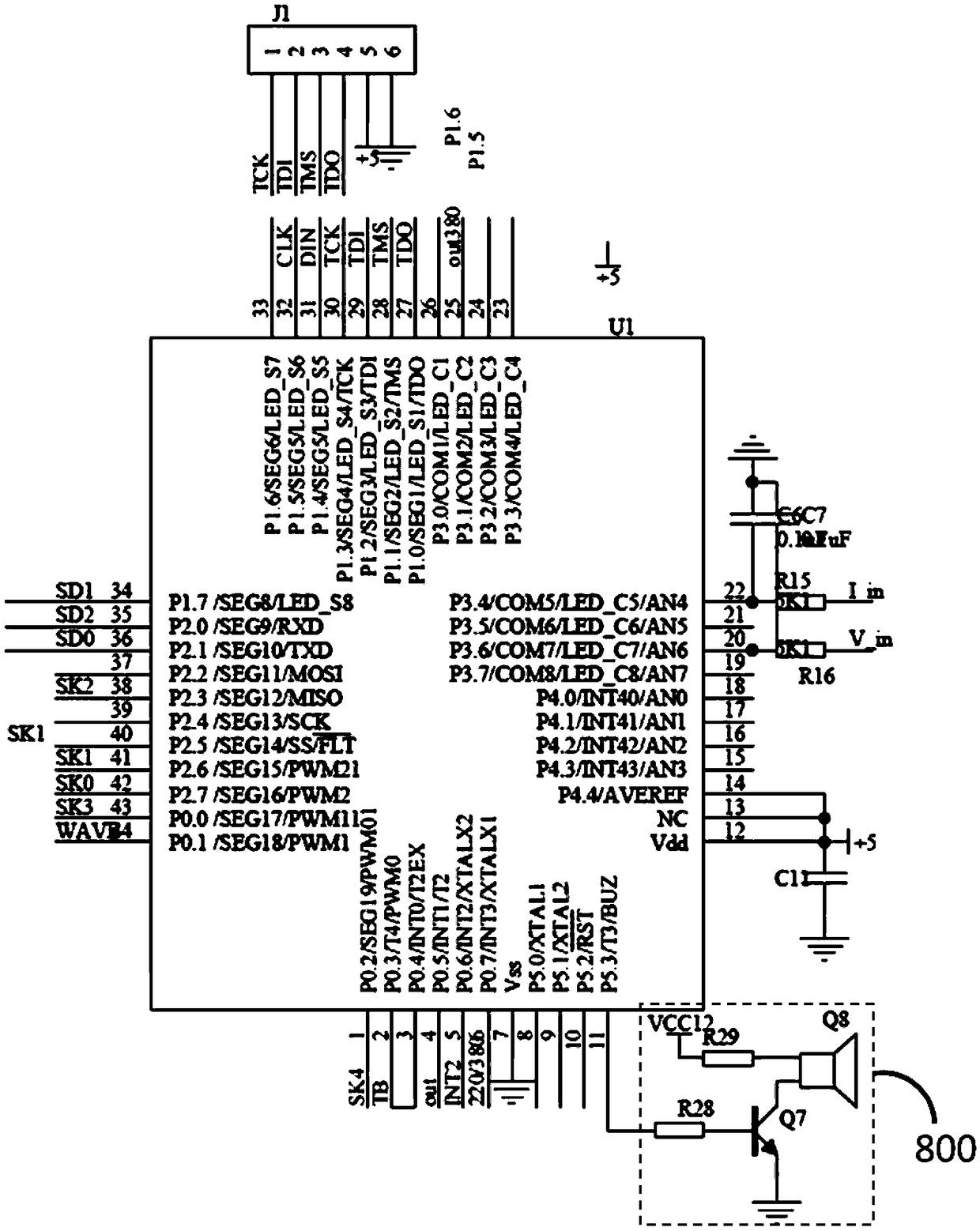

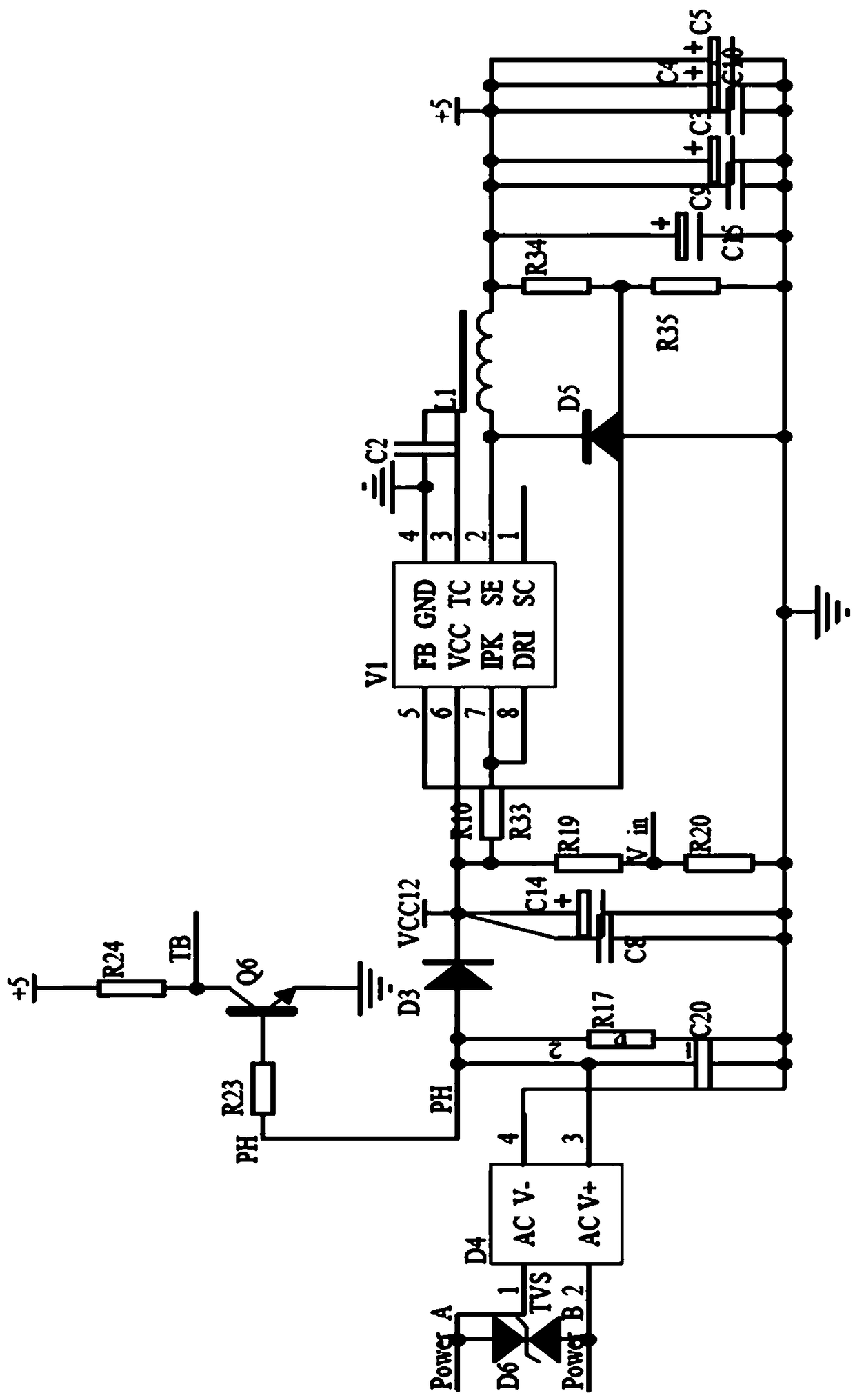

[0032] The plastic welding machine control system is an indispensable content for controlling the plastic welding machine to perform plastic welding work. There are generally three control methods in the existing plastic welding machine control system: the first one is to connect the hot-melt sleeve resistor that needs to be plastic welded. Network, the user observes the ammeter while manually adjusting the current, and then sets the plastic welding working time of the timer according to the work experience, and the input voltage is generally fixed, such as 380V; the second method, compared with the first method , can realize manual switching of working voltage; third, on the basis of the second step, a voltage judgment mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com