A preparation method of gallium-containing zeolite and its application in coal pyrolysis volatile modification

A technology of zeolite and gallium source, which is applied in the field of preparation of gallium-containing zeolite to achieve the effects of reducing carbon deposition and deactivation, easy operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Under stirring conditions, first take 10.58g TPAOH and 0.233mL 10mol / L NaOH solution and add it to 10.81g water, then add 1.97g TPOAC to form a transparent solution A;

[0063] (2) Add 12.5g of LUDOX HS-40 dropwise to solution A, stir for 1 hour after dropping, add 0.21g of gallium nitrate hydrate and 0.35g of aluminum isopropoxide, and then stir for 0.5h for aging;

[0064] (3) Transfer the solution obtained in step (2) from aging at room temperature to a stainless steel reaction kettle lined with polytetrafluoroethylene, crystallize at 140°C for 4 days, filter and wash with suction, dry at 105°C, and then roast at 550°C 6h;

[0065] (4) The solid obtained in step (3) is subjected to ammonium nitrate ion exchange, washed three times, dried, and then roasted at 550° C. for 6 hours to obtain a hierarchically porous micron-scale gallium-containing framework molecular sieve with an MFI framework structure.

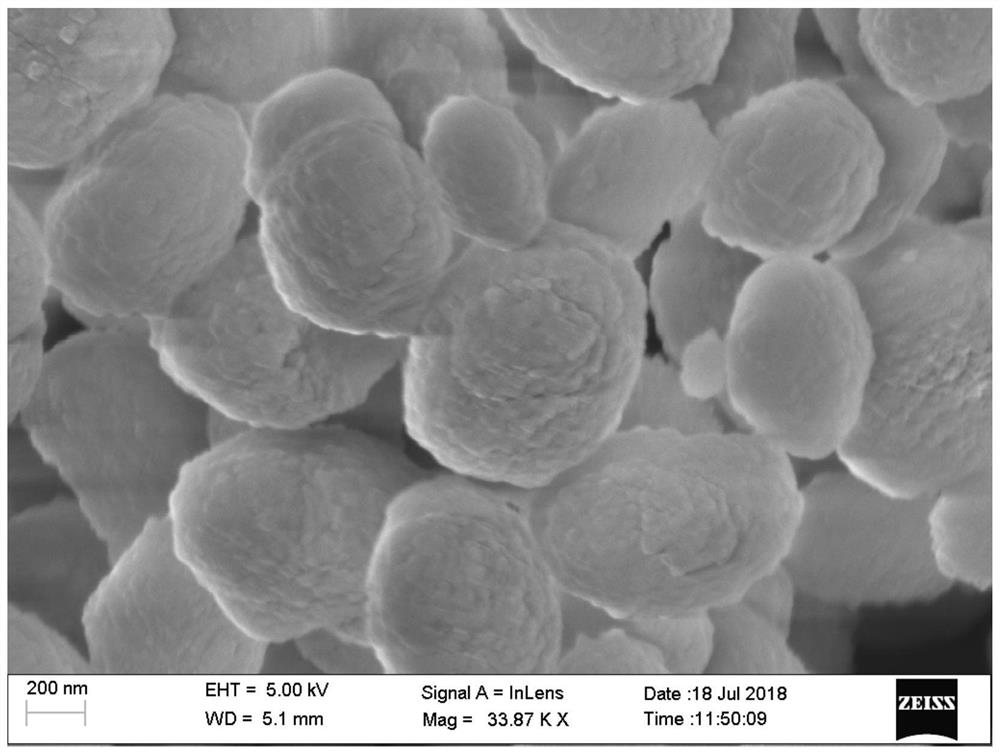

[0066] see Figure 5 , the molecular sieve prepared by this...

Embodiment 2

[0068] (1) Under stirring conditions, first take 10.58g TPAOH and 0.233mL 10mol / L NaOH solution and add it to 10.81g water, then add 1.97g TPOAC to form a transparent solution A;

[0069] (2) Add 12.5g of LUDOX HS-40 dropwise to A, stir for 1 hour, then add 0.21g of gallium nitrate hydrate and 0.087g of aluminum isopropoxide, and stir for 0.5 hours;

[0070] (3) Transfer the solution obtained in step (2) from aging at room temperature to a stainless steel reaction kettle lined with polytetrafluoroethylene, crystallize at 140°C for 4 days, filter and wash with suction, dry at 105°C, and then roast at 550°C 6h;

[0071] (4) The solid obtained in step (3) was ion-exchanged with ammonium nitrate, washed three times, dried, and then calcined at 550° C. for 6 hours to obtain a hierarchically porous micron-scale framework-containing gallium-aluminum molecular sieve with an MFI framework structure.

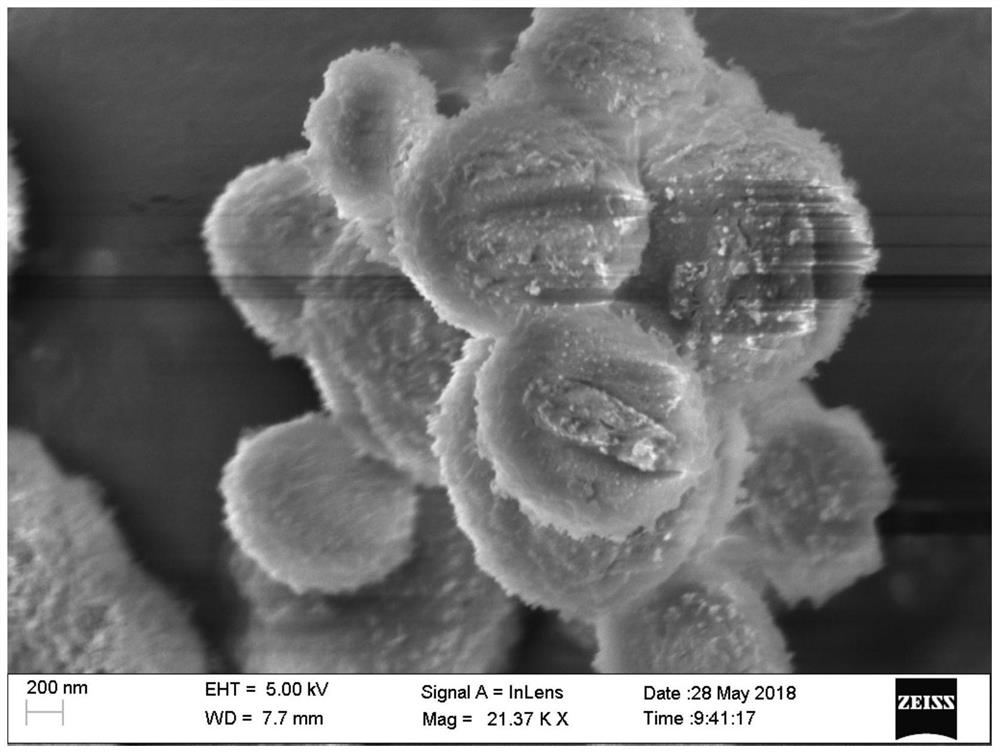

[0072] see Image 6 , the molecular sieve prepared by this method can also observe ...

Embodiment 3

[0074] (1) Under stirring conditions, first take 10.58g TPAOH and 0.233mL 10mol / L NaOH solution and add it to 10.81g water, then add 1.97g TPOAC to form a transparent solution A;

[0075] (2) Add 12.5g of LUDOX HS-40 dropwise to A, stir for 1h, then add 0.21g of gallium nitrate hydrate and 0,17g of aluminum isopropoxide, and stir for 0.5h;

[0076] (3) Transfer the solution obtained in step (2) from aging at room temperature to a stainless steel reaction kettle lined with polytetrafluoroethylene, crystallize at 140°C for 4 days, filter and wash with suction, dry at 105°C, and then roast at 550°C 6h;

[0077] (4) The solid obtained in step (3) was ion-exchanged with ammonium nitrate, washed three times, dried, and then calcined at 550° C. for 6 hours to obtain a hierarchically porous micron-scale framework-containing gallium-aluminum molecular sieve with an MFI framework structure.

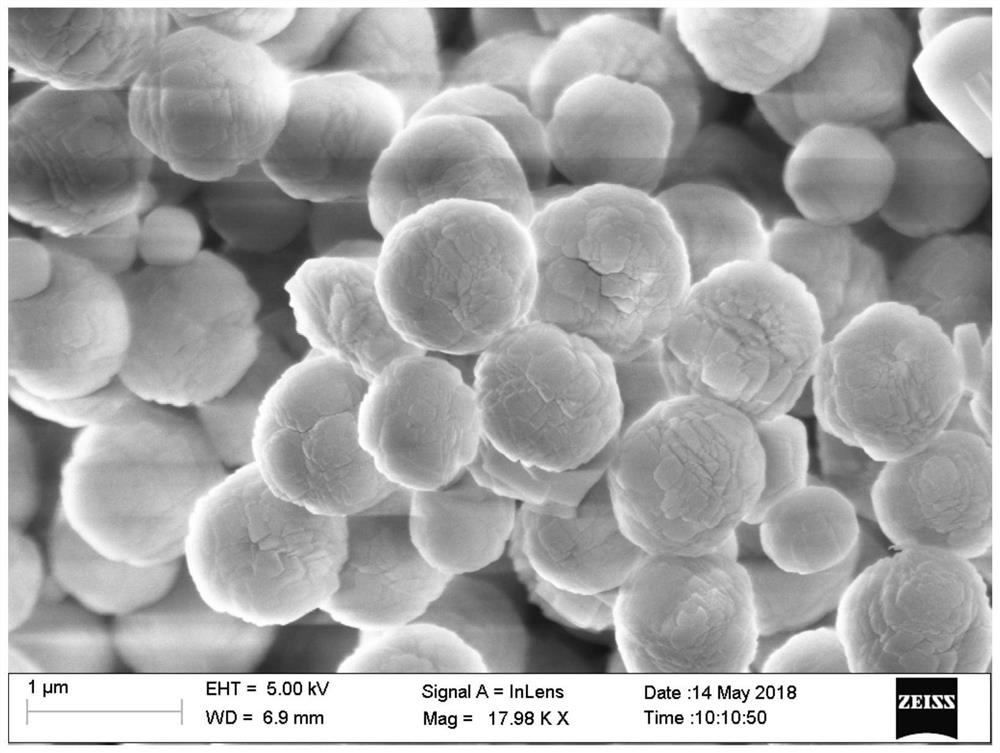

[0078] see Figure 7 The molecular sieve synthesized by this method can also observe obvious ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com