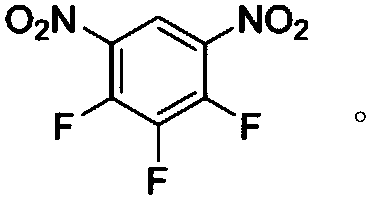

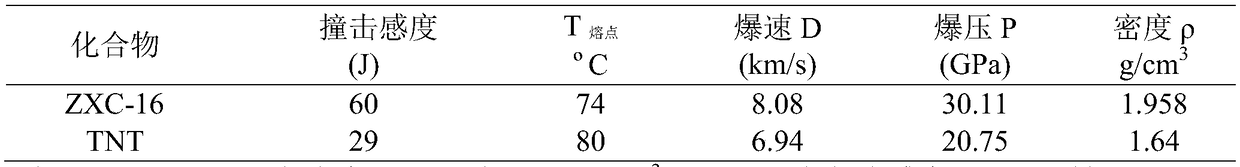

Preparation method of melt-cast explosive 2, 3, 4-trifluoro-1, 5 dinitrobenzene

A technology of trifluoronitrobenzene and dinitrobenzene, which is applied in the field of compound preparation, can solve the problems of ammunition sensitivity, fragility and transportation impact, hazards to workers’ health and the environment, oil leakage of explosives, etc., and achieve superior performance, The effect of safe raw materials and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method for melting and casting explosive 2,3,4-trifluoro-1,5-dinitrobenzene (ZXC-16), comprising the following steps:

[0020] Under ice-water bath, weigh potassium nitrate 5.55g (55mmol, 1.1eq) and slowly add in the cold 50ml concentrated sulfuric acid (concentration of sulfuric acid is 95%), continue to stir until potassium nitrate dissolves completely after adding, then, slowly Add 8.85g (50mmol, 1.0eq) of 2,3,4-trifluoronitrobenzene. After the addition, continue stirring at room temperature until the reaction is complete (TLC detection).

[0021] After the reaction was complete, the reaction mixture was slowly poured into ice water, a large amount of precipitates were precipitated, filtered, washed with water, and dried to obtain a light yellow solid with a yield of 89.01%.

[0022] Its H NMR spectrum is 1 H NMR (600MHz, CDCl 3 -d 1 )δppm: 8.79m, 1H); 13 C NMR (125MHz, CDCl3-d1); δppm: 150.68-148.91(d), 143.10-141.33(d), 133.24, 118.07; 19 F NMR (...

Embodiment 2

[0024] A preparation method for melting and casting explosive 2,3,4-trifluoro-1,5-dinitrobenzene (ZXC-16), comprising the following steps:

[0025] Under ice-water bath, weigh ammonium nitrate 4.4g (55mmol, 1.1eq) and add slowly in cold 50ml concentrated sulfuric acid (concentration of sulfuric acid is 95%), after adding, continue to stir until potassium nitrate dissolves completely, then, slowly Add 8.85g (50mmol, 1.0eq) of 2,3,4-trifluoronitrobenzene. After the addition, continue stirring at room temperature until the reaction is complete (TLC detection).

[0026] After the reaction was complete, the reaction mixture was slowly poured into ice water, a large amount of precipitates were precipitated, filtered, washed with water, and dried to obtain a light yellow solid with a yield of 86.67%.

Embodiment 3

[0028] A preparation method for melting and casting explosive 2,3,4-trifluoro-1,5-dinitrobenzene (ZXC-16), comprising the following steps:

[0029] Under ice-water bath, weigh potassium nitrate 5.55g (55mmol, 1.1eq) and slowly add in cold 50ml concentrated sulfuric acid (concentration of sulfuric acid is 98%), after adding, continue to stir until potassium nitrate dissolves completely, then, slowly Add 8.85g (50mmol, 1.0eq) of 2,3,4-trifluoronitrobenzene. After the addition, continue stirring at room temperature until the reaction is complete (TLC detection).

[0030] After the reaction was complete, the reaction mixture was slowly poured into ice water, a large amount of precipitates were precipitated, filtered, washed with water, and dried to obtain a light yellow solid with a yield of 87.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com