A method for preparing adhesive reducer from amphoteric polyether polycarboxylic acid compound

A technology of carboxylic acid compound and glue reducer, which is applied in the field of preparing glue reducer from amphoteric polyether polycarboxylate compounds, can solve the problem of large difference in molecular structure types, restricts the application and development of glue reducer, and has no steric hindrance. It can achieve the effect of good adaptability, ensuring steric hindrance and delaying hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

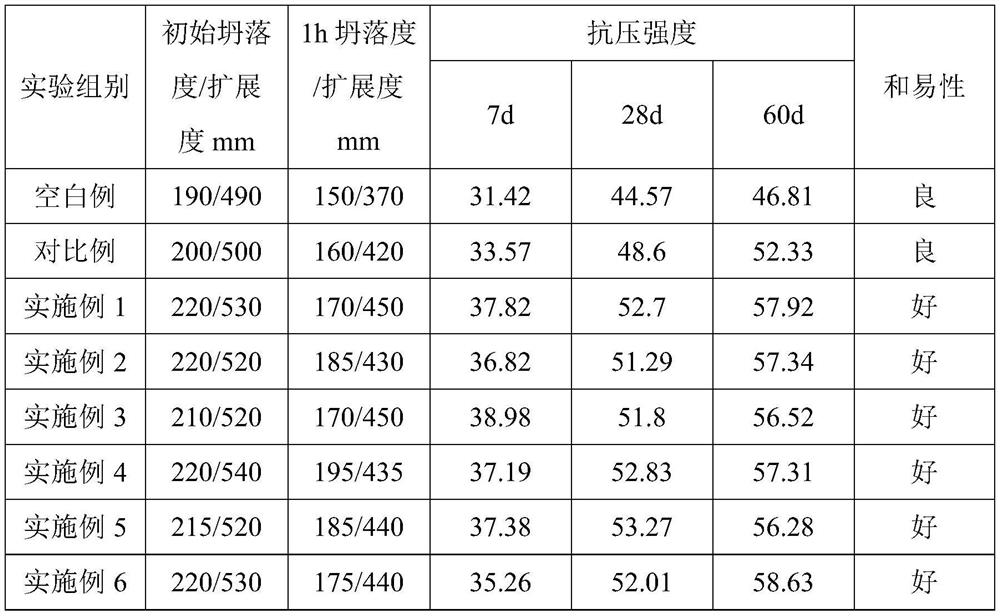

Examples

Embodiment 1

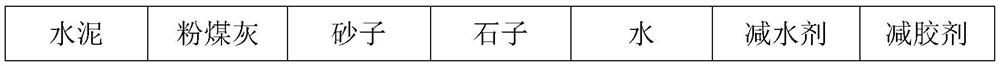

[0045] Embodiment 1 (each component consumption is parts by weight)

[0046] 1. Preparation of amphoteric polyether polycarboxylic acid compound: the amphoteric polyether polycarboxylic acid compound is prepared from the following components by weight, and the preparation method is carried out according to the following steps:

[0047] 1), 290 parts of 800-molecule allyl polyoxyethylene ether, 5 parts of methacryloyloxyethyltrimethylammonium chloride, 2 parts of sodium vinyl sulfonate, and 1.5 parts of dimethyl-vinyl phosphate and 180 parts of water are added to the reactor, stirred and heated until it dissolves;

[0048] 2), measure the temperature in the kettle, control the temperature at 35°C, and after the temperature is stable, add 3.7 parts of 27.5% industrial grade hydrogen peroxide at one time;

[0049] 3) After 5 minutes, start to drop solution B and solution A in sequence. After solution B is added, start to add solution A dropwise within 10 minutes. The time for ad...

Embodiment 2

[0052] Embodiment 2 (each component consumption is parts by weight)

[0053] 1. Preparation of amphoteric polyether polycarboxylic acid compound: the amphoteric polyether polycarboxylic acid compound is prepared from the following components by weight, and the preparation method is carried out according to the following steps:

[0054] 1), 295 parts of 800 molecular weight methallyl polyoxyethylene ether, 4 parts of methacryloylpropyltrimethylammonium chloride, 1.8 parts of sodium acrylsulfonate, polyoxyethylene ether glycerol phosphate Add 1.4 parts and 185 parts of water into the reaction kettle, stir and heat until it dissolves;

[0055] 2), measure the temperature in the kettle, control the temperature at 36°C, and after the temperature is stable, add 3.5 parts of 27.5% industrial grade hydrogen peroxide at one time;

[0056] 3) After 5 minutes, start to drop solution B and solution A in sequence. After solution B is added, start to add solution A dropwise within 10 minut...

Embodiment 3

[0059] Embodiment 3 (each component consumption is parts by weight)

[0060] 1. Preparation of amphoteric polyether polycarboxylic acid compound: the amphoteric polyether polycarboxylic acid compound is prepared from the following components by weight, and the preparation method is carried out according to the following steps:

[0061] 1), 300 parts of 800 molecular weight isopentenol polyoxyethylene ether, 3 parts of methacryloylpropyltrimethylammonium chloride, 0.5 parts of sodium acrylsulfonate, 1.3 parts of methacryloyloxyethyl phosphate 190 parts and 190 parts of water are added to the reactor, stirred and heated until it dissolves;

[0062] 2), measure the temperature in the kettle, control the temperature at 37°C, after the temperature is stable, add 3 parts of 27.5% by mass industrial grade hydrogen peroxide at one time;

[0063] 3) After 5 minutes, start to drop solution B and solution A in sequence. After solution B is added, start to add solution A dropwise within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com