Efficient and mild type detergent and production equipment thereof

A technology for production equipment and detergent, applied in transportation and packaging, detergent composition, detergent compounding agent, etc., can solve the problems of large skin impact, achieve solubilization irritation, excellent performance, high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

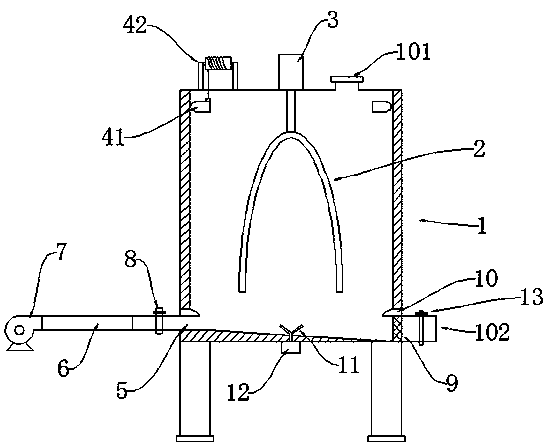

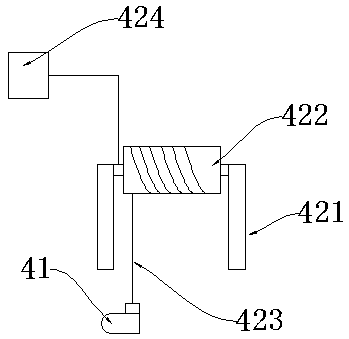

Image

Examples

Embodiment 1

[0035] A high-efficiency mild detergent, comprising the following components by weight: 2 parts of active enzyme, 15 parts of hydroxy synthetic alcohol polyoxyethylene ether, 10 parts of APG, 5 parts of MES, 8 parts of fatty alcohol polyoxyethylene ether, 3 parts Part sodium methyl lauroyl taurate, 15 parts fatty acid methyl ester ethoxylate, 3 parts salt, 20 parts deionized water, 1 part methylisothiazolinone, 1 part limonene, and 1 part linalool . Its preparation method comprises the following steps:

[0036] S1: Mix APG, hydroxy synthetic alcohol polyoxyethylene ether, MES, sodium methyl lauroyl taurate and fatty acid methyl ester ethoxylate in proportion, add 1 / 3 of the total amount of water, and stir at 56°C for 20 minutes , then add salt and stir for 20min, the speed of twice stirring is 250rpm, obtain thick material;

[0037] S2: Take half of the remaining water, add fatty alcohol polyoxyethylene ether, and stir at 30°C for 25 minutes to obtain a solvent;

[0038] S3: ...

Embodiment 2

[0040] A high-efficiency mild detergent, comprising the following components by weight: 3 parts of active enzymes, 18 parts of hydroxy synthetic alcohol polyoxyethylene ether, 12 parts of APG, 6 parts of MES, 10 parts of fatty alcohol polyoxyethylene ether, 4 parts Parts sodium methyl lauroyl taurate, 18 parts fatty acid methyl ester ethoxylate, 4 parts salt, 25 parts deionized water, 1.5 parts methylisothiazolinone, 1.5 parts limonene, and 1.5 parts linalool . Its preparation method comprises the following steps:

[0041] S1: Mix APG, hydroxy synthetic alcohol polyoxyethylene ether, MES, sodium methyl lauroyl taurate and fatty acid methyl ester ethoxylate in proportion, add 1 / 2 of water, stir at 58°C for 30min, then Add salt and stir for 30min, the speed of the two stirrings is 280rpm, to obtain a thick material;

[0042] S2: Take half of the remaining water, add fatty alcohol polyoxyethylene ether, and stir at 35°C for 28 minutes to obtain a solvent;

[0043] S3: Mix the ...

Embodiment 3

[0045] A high-efficiency mild detergent, comprising the following components by weight: 5 parts of active enzyme, 20 parts of hydroxy synthetic alcohol polyoxyethylene ether, 15 parts of APG, 8 parts of MES, 12 parts of fatty alcohol polyoxyethylene ether, 5 parts Parts sodium methyl lauroyl taurate, 20 parts fatty acid methyl ester ethoxylate, 5 parts salt, 30 parts deionized water, 2 parts methylisothiazolinone, 2 parts limonene, and 2 parts linalool . Its preparation method comprises the following steps:

[0046] S1: Mix APG, hydroxy synthetic alcohol polyoxyethylene ether, MES, sodium methyl lauroyl taurate and fatty acid methyl ester ethoxylate in proportion, add 1 / 2 of water, stir at 60°C for 30min, then Add salt and stir for 30 minutes, and the speed of the two stirrings is 300 rpm to obtain a thick material;

[0047] S2: Take half of the remaining water, add fatty alcohol polyoxyethylene ether, and stir at 40°C for 30 minutes to obtain a solvent;

[0048] S3: Mix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com