Impeller suitable for supercritical carbon dioxide centripetal turbine with grade being 5-6 MW and modeling method of impeller blades

A technology of carbon dioxide and impeller blades, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of impeller blades with uneven surface, single type of impeller, and short service life, and achieve small aerodynamic loss and aerodynamic The effect of high efficiency and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

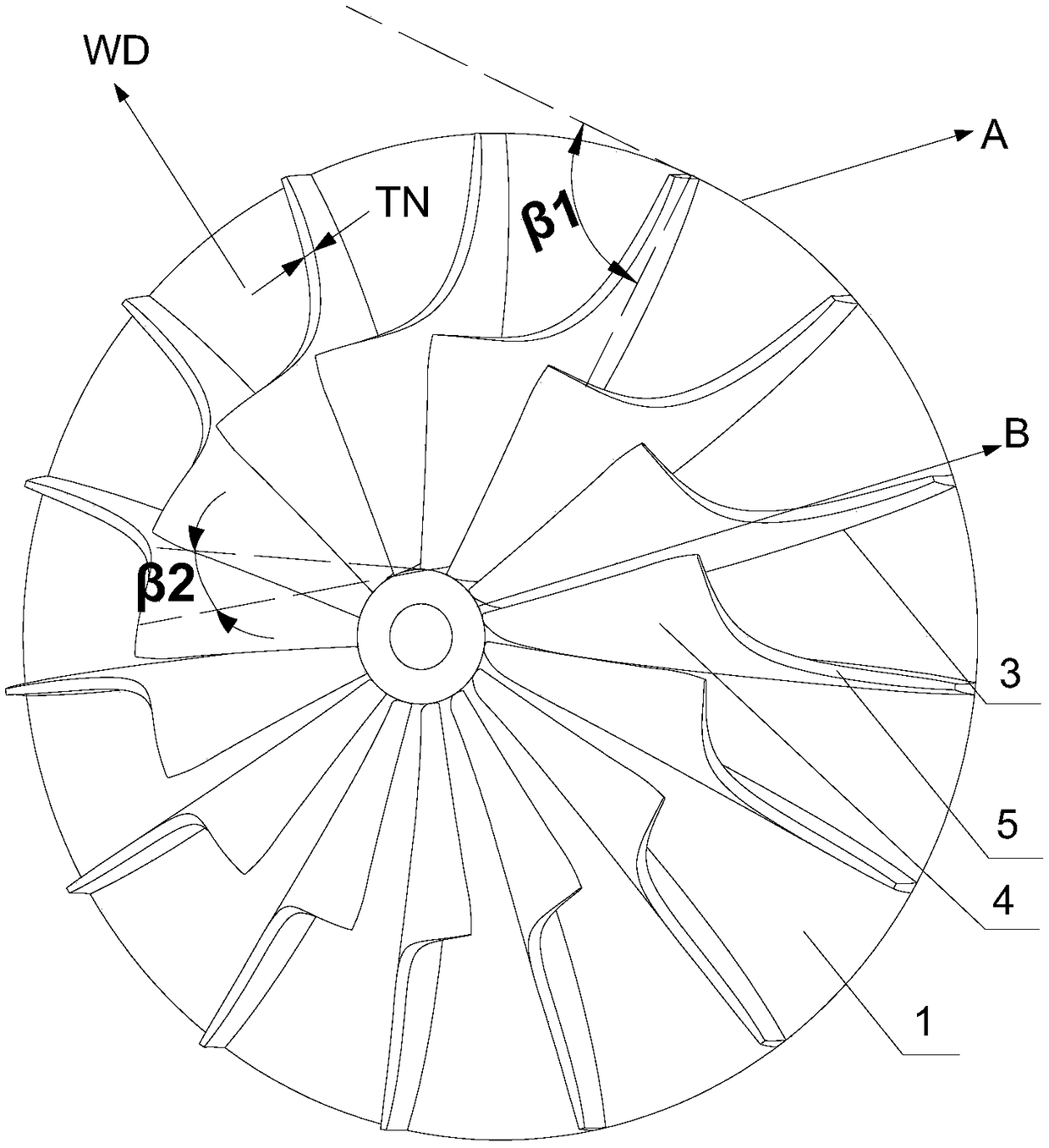

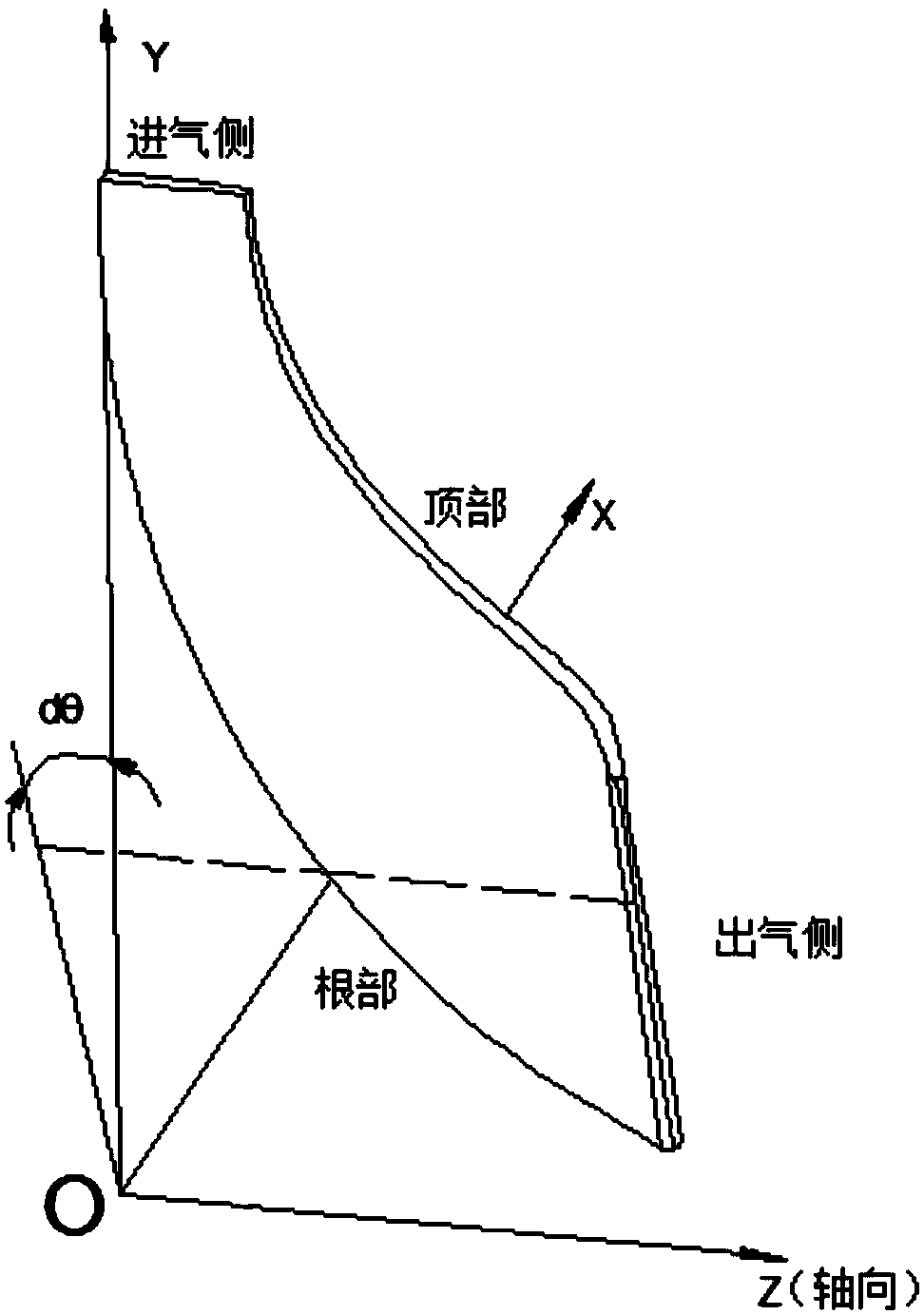

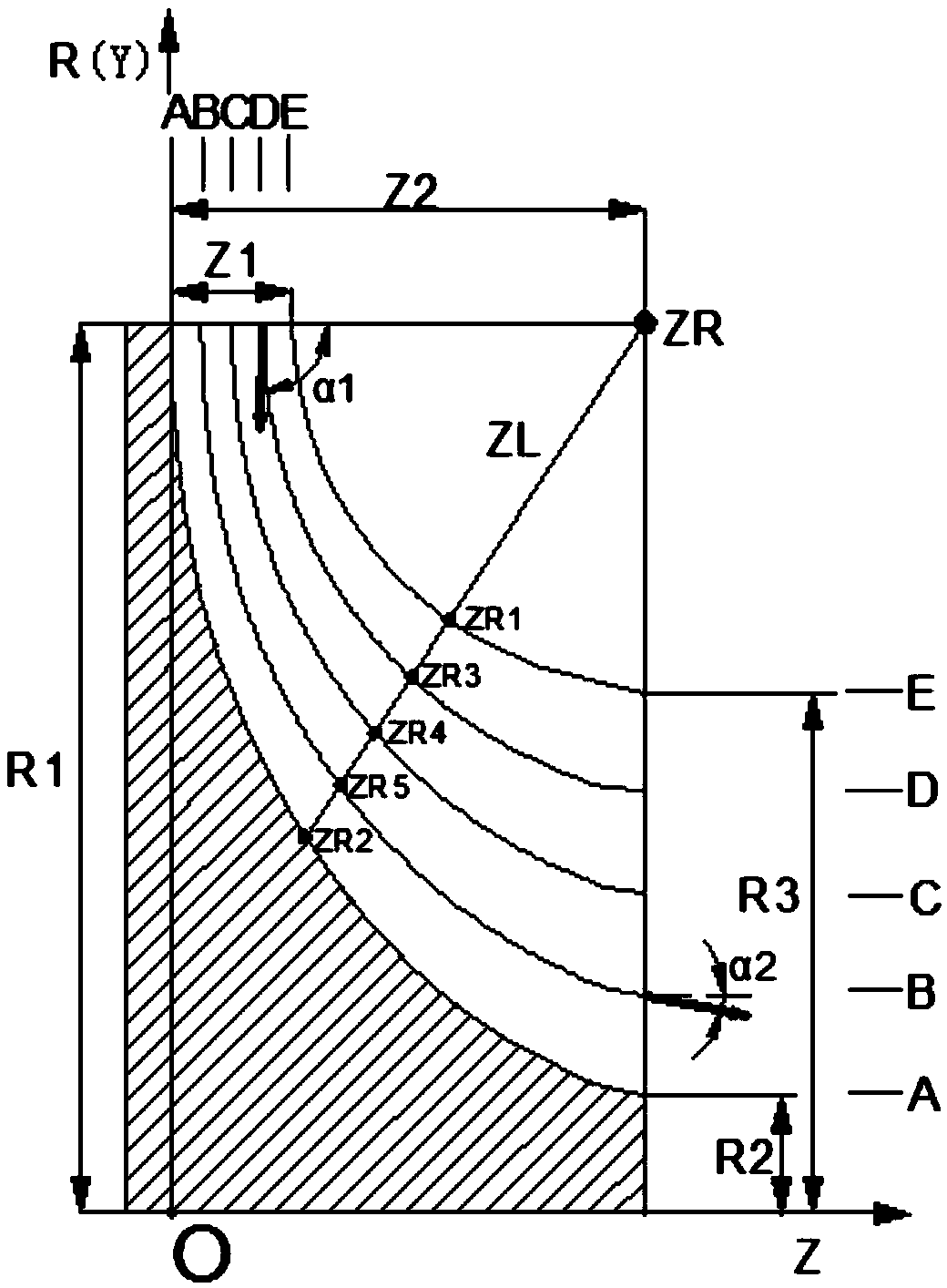

[0064] to combine figure 1 and Figure 4 To describe this embodiment, the impeller blade of this embodiment is formed by sweeping five blade-shaped curved surfaces a, b, c, d, and e along the radial direction, and the blade-shaped lines of each section are spatial curves. It is characterized in that the impeller blades determine the profile parameters of the five cross-sectional blade shapes and their changing rules from the side close to the wheel disc to the side of the wheel cover: the meridian surface profile and the Z-θ flow surface profile of the mid-arc are defined, and the blade thickness is along the Axial distribution law. Express the profile parameters and their changing rules in the form of cylindrical coordinates.

specific Embodiment approach 2

[0065] to combine figure 1 and figure 2 To illustrate this embodiment, the number of blades of the impeller is selected to be 15, considering factors such as blade strength, working fluid flow uniformity, and friction loss. Taking the Z axis as the rotation axis, 15 blades are evenly distributed in the entire circumference, and the rotation angle of two adjacent blades is 24°. Form an integral body with the wheel WD by casting or welding.

specific Embodiment approach 3

[0066] to combine Figure 5 To illustrate this embodiment, the present invention adopts a parametric modeling method to establish the section profile of the blade. Since the profile of the blade is a spatial curve, it is easier to express and model in the form of a cylindrical coordinate system. The position of point M in the Cartesian coordinate system is expressed as (x, y, z), and in the cylindrical coordinate system, it can still be expressed by an ordered array (R, θ, Z). The conversion relationship of the coordinates of the same position in the cylindrical coordinate system and the rectangular coordinate system is:

[0067] x=Rsin(θ)

[0068] y=Rcos(θ)

[0069] z=Z

[0070] In the formula: R is the distance between the origin O and the projection M' of point M on the plane XOY, that is, the vertical distance between point M and the Z axis; θ is viewed from the positive direction of the Z axis, and rotates counterclockwise from the Y axis The angle turned to OM'; Z is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com