Rubbish gasification combustion heat source furnace for reducing tetrachlorodibenzo-p-dioxin emission

A heat source and garbage technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as incomplete combustion, uneven feed, garbage siege, etc., to prolong the combustion time, promote full combustion, and avoid dioxins the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

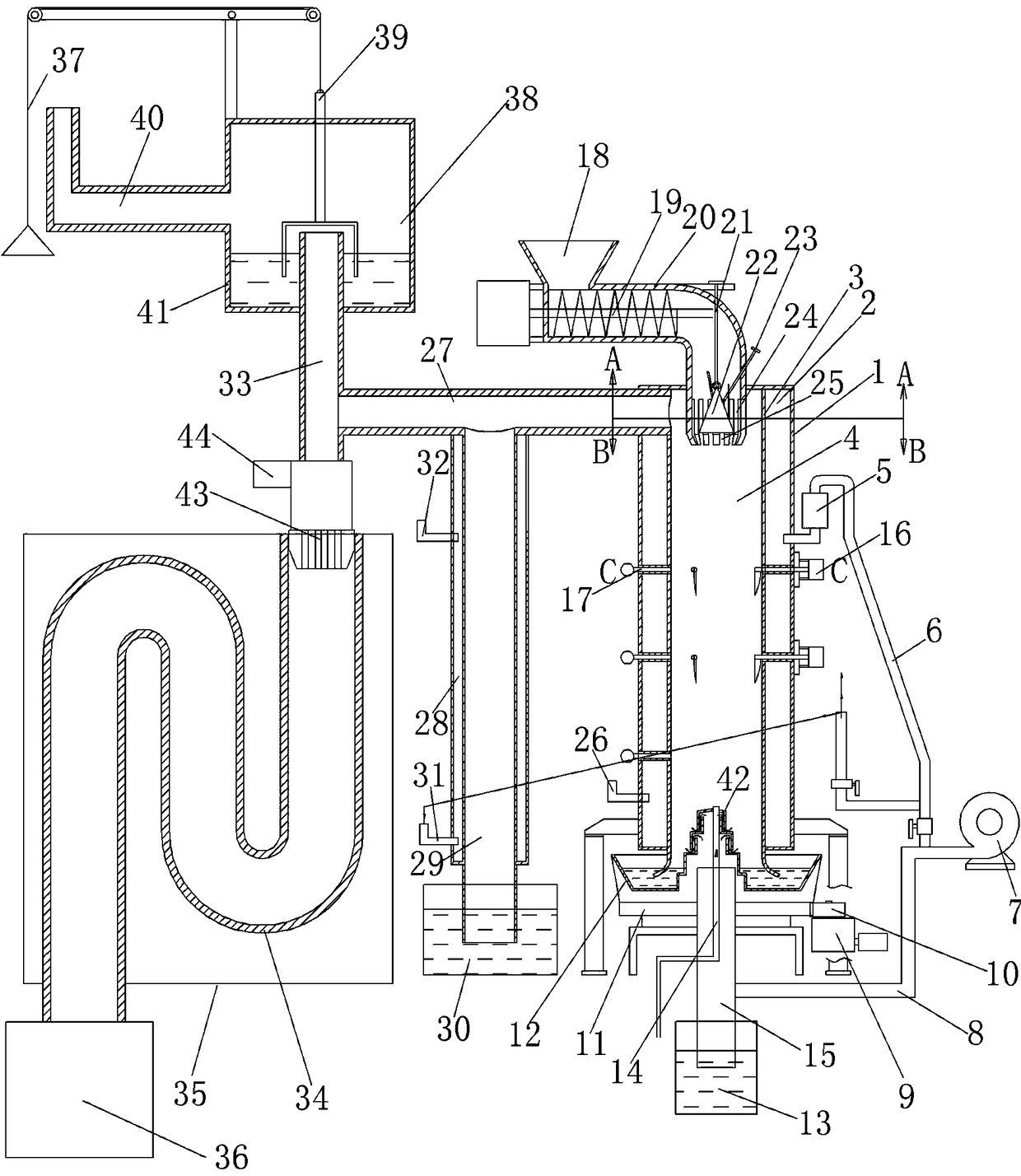

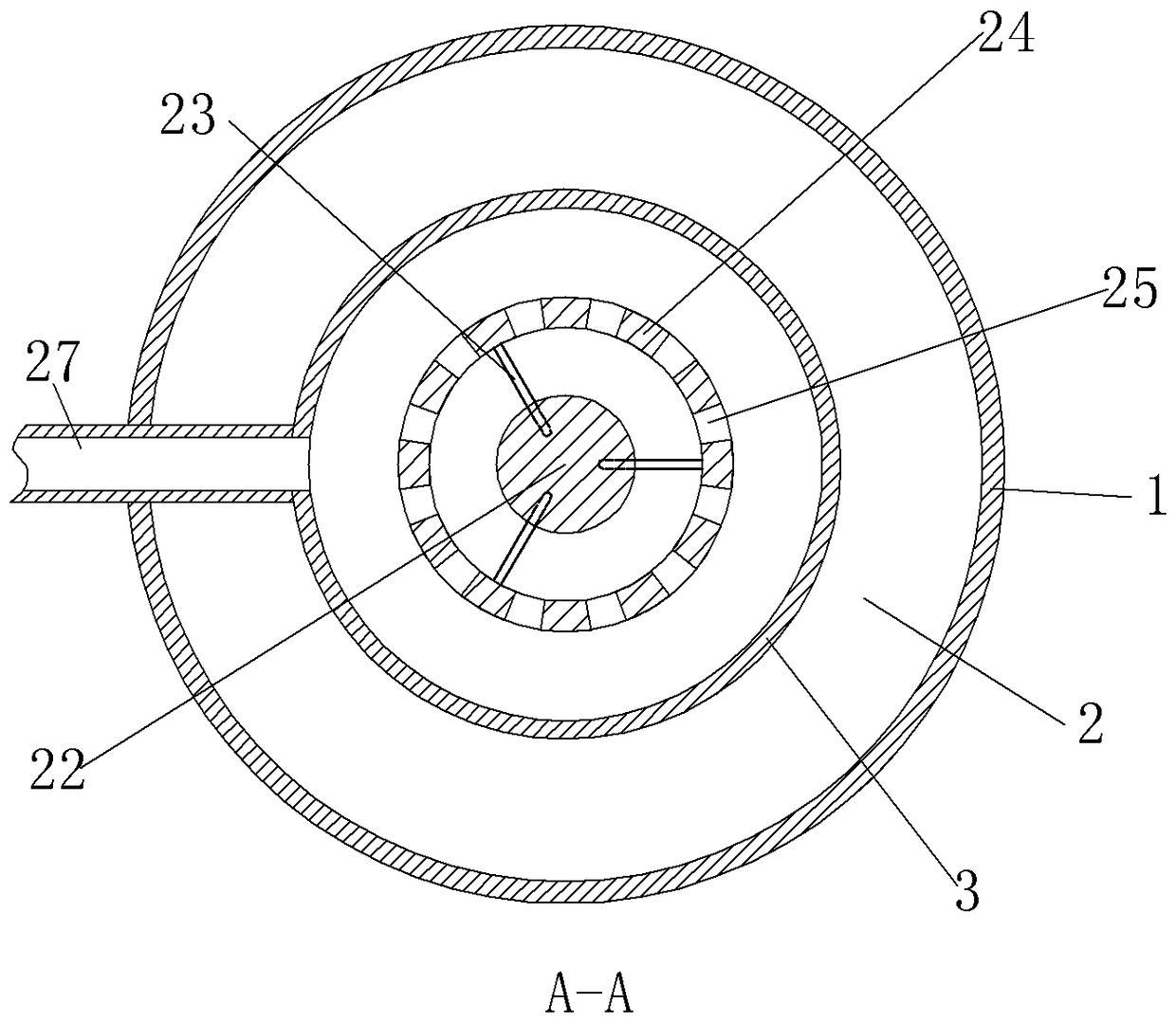

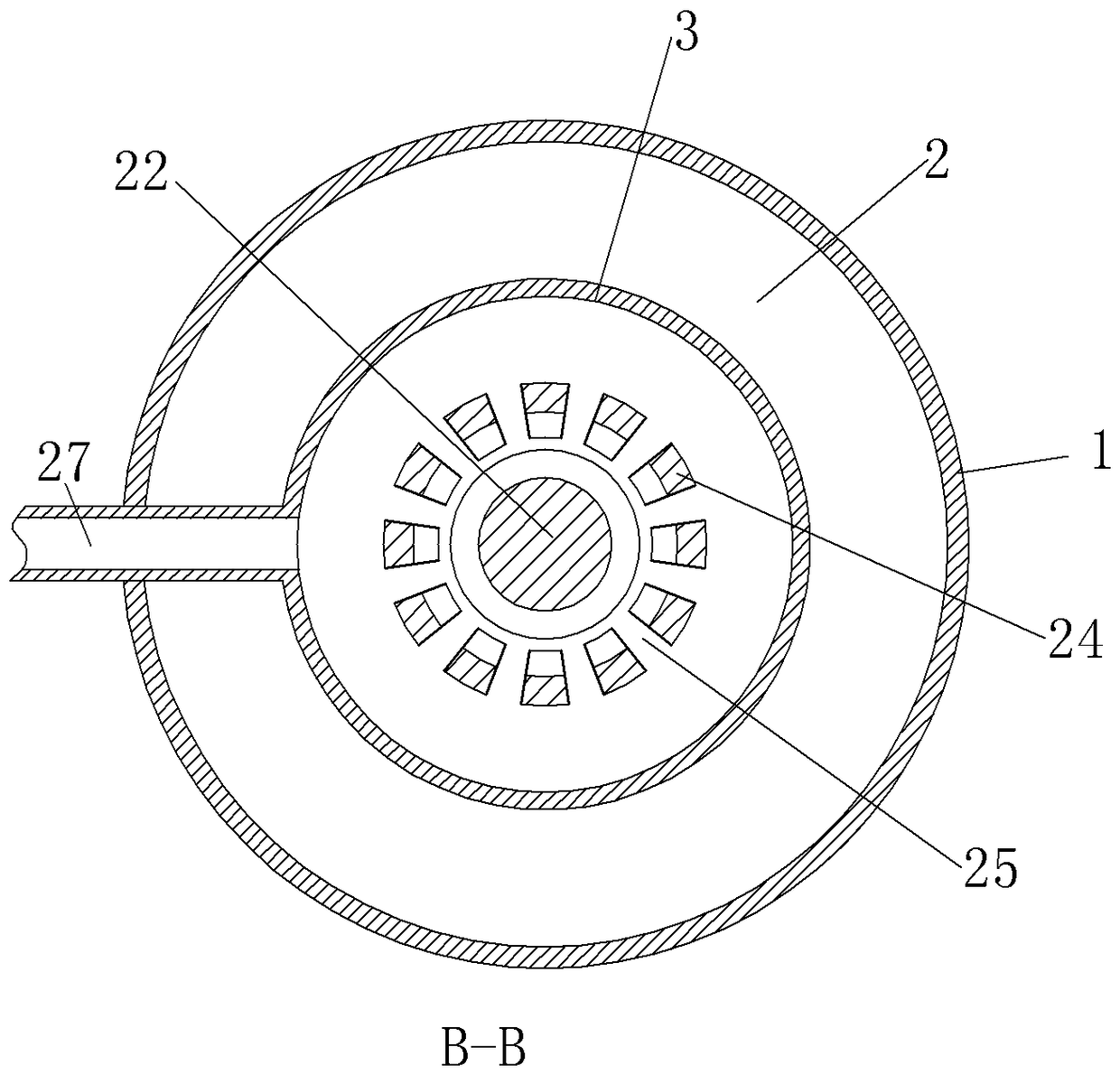

[0016] Embodiment one: see Figure 1-5 , a waste gasification combustion heat source furnace for reducing dioxin emissions in the figure. The furnace includes a furnace body, a feeding device, a ventilation mechanism and a combustible gas discharge channel. pipes and steam exhaust pipes, so that the furnace body is divided into an inner shell and an outer shell; the feeding device is a screw propeller type feeding device, including the above pipe body, hopper, and auger, and at the inner end of the pipe body In order to bend downward and penetrate into the discharge section inside the inner shell, the lower end of the discharge section is an opening, and the discharge section is provided with several leakage gaps arranged along the direction of the discharge section bus line on the circumference. There are several material stop strips between the material gaps, and the lower end of each material stop bar is provided with an inwardly curved material guide hook; a conical adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com