Metal wire surface treatment device

A technology for surface treatment devices and metal wires, applied in metal processing equipment, grinding/polishing safety devices, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of poor surface treatment quality of metal wires and the efficiency of metal wire surface treatment Low-level problems, to achieve high quality, good processing effect, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

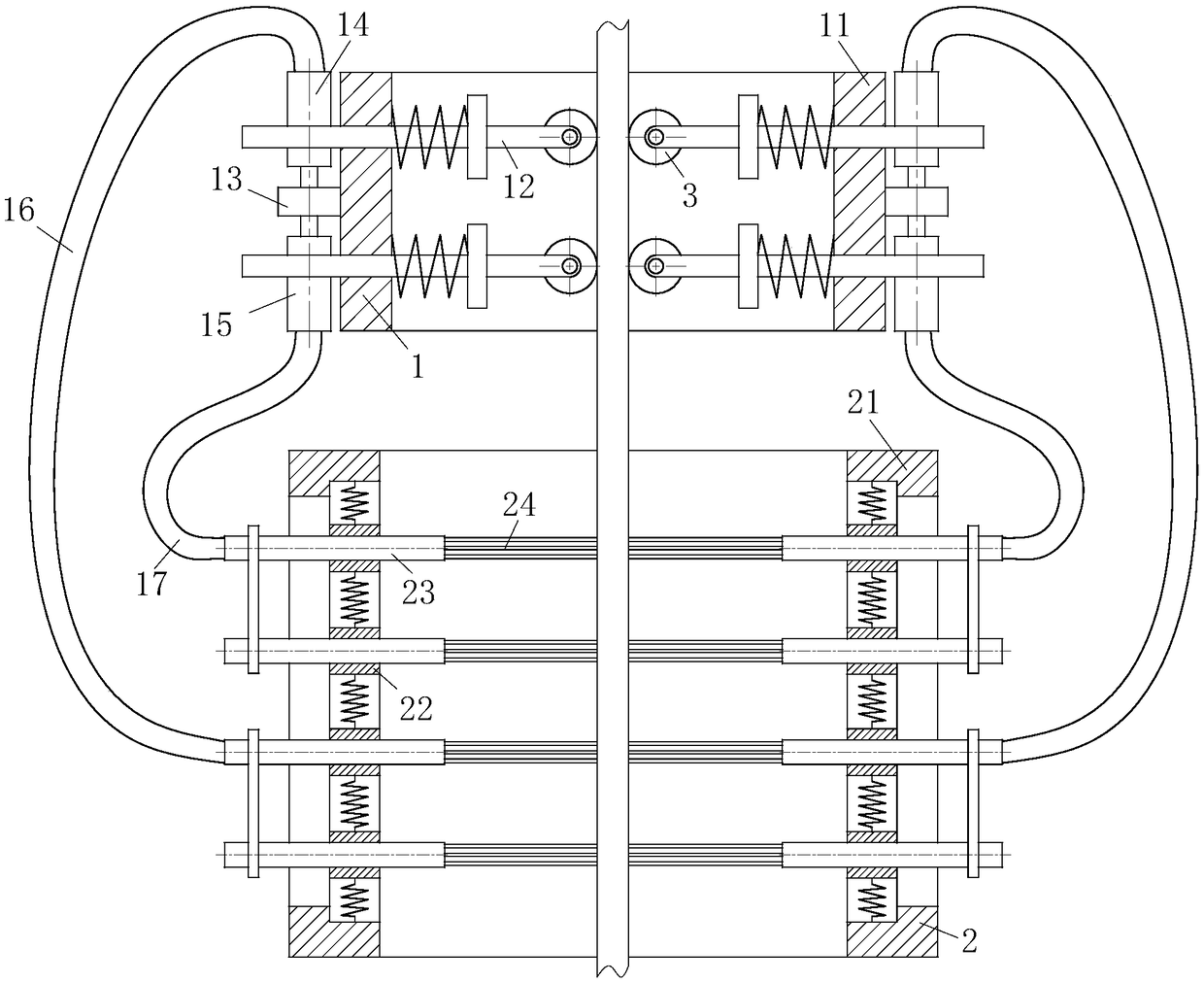

[0017] use as Figure 1-Figure 3 A metal wire surface treatment device according to an embodiment of the present invention will be described as follows.

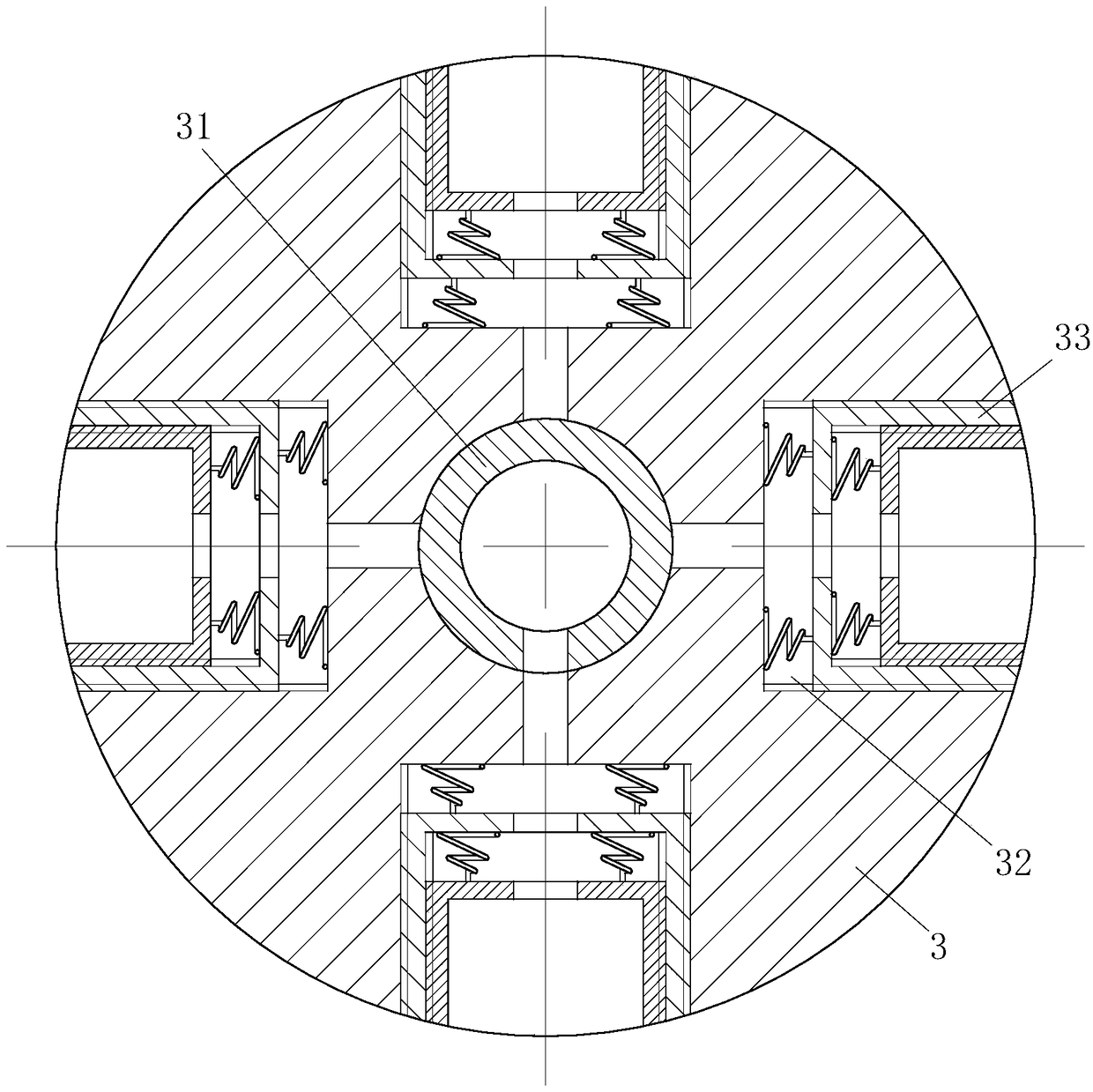

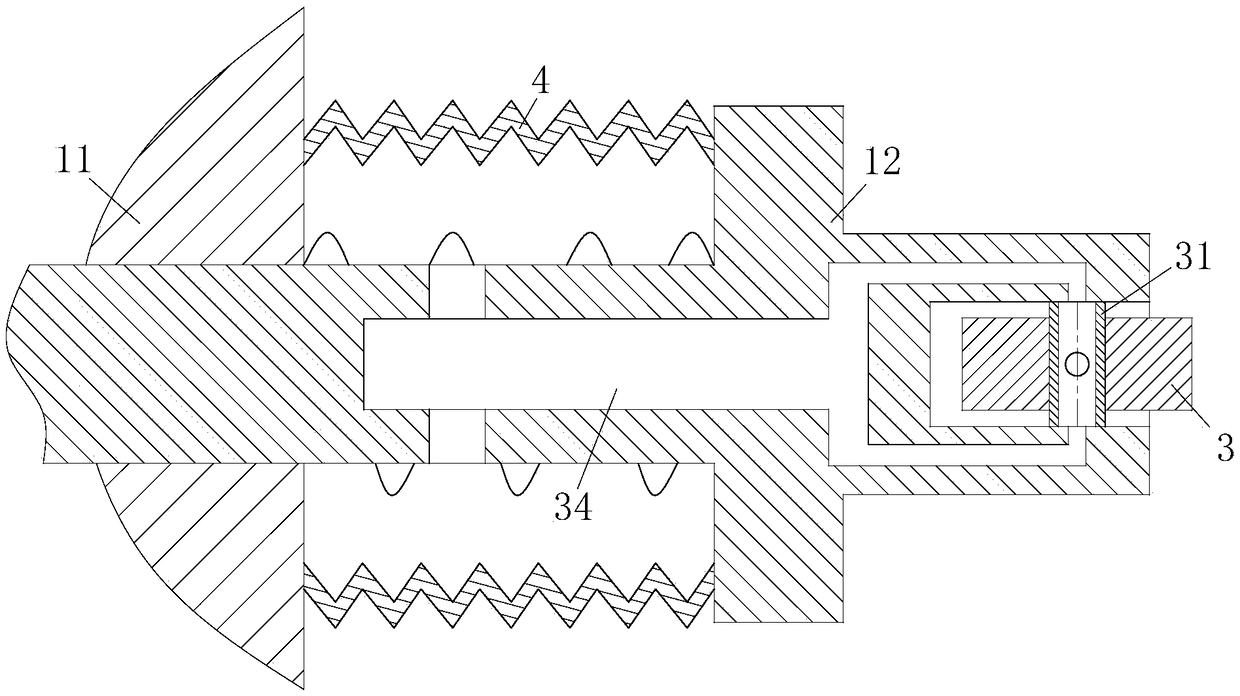

[0018] Such as figure 1 As shown, a metal wire surface treatment device according to the present invention includes a grinding module 1 and a cleaning module 2, the grinding module 1 is used for grinding the surface of the metal wire, and the cleaning module 2 is used for assisting in removing foreign matter on the surface of the metal wire and removing The foreign matter polished by the grinding module 1; the grinding module 1 includes an annular grinding frame 11, and two sets of connecting rods 12 are slidably installed in the grinding frame 11. The number of connecting rods 12 in each group is not less than three, and the connecting rods 12 Evenly distributed around the axis of the grinding frame 11, the connecting rod 12 is located inside the grinding frame 11 and is provided with a disc protrusion. A spring is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com