A w with electrochromic properties 18 o 49 /wo 3 Composite film and preparation method thereof

A composite film, electrochromic technology, applied in the coating and other directions, can solve the problems of seed crystal thickness, uniformity, and the surface state is not easy to adjust, and achieve the effect of low cost, simple process, and improved bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

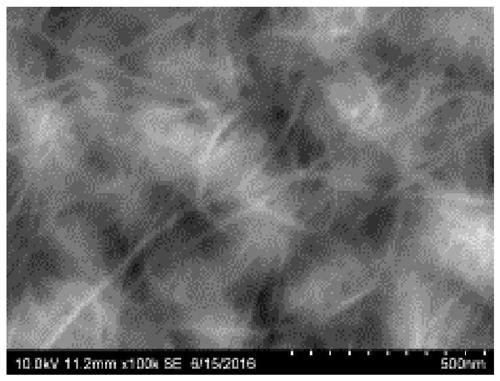

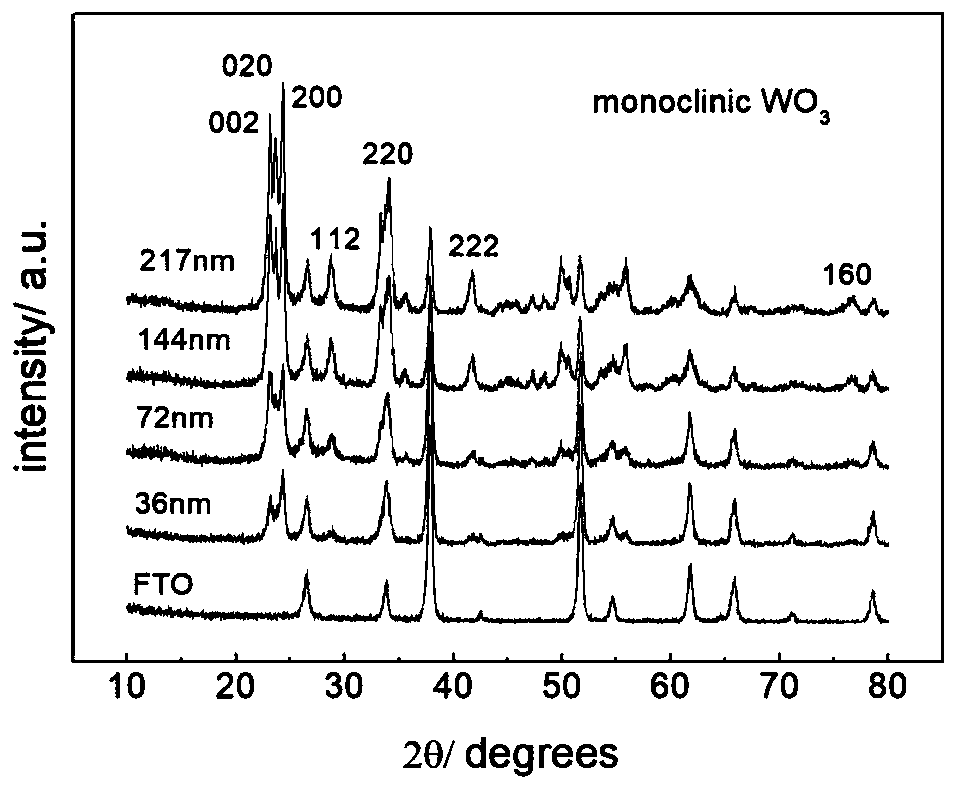

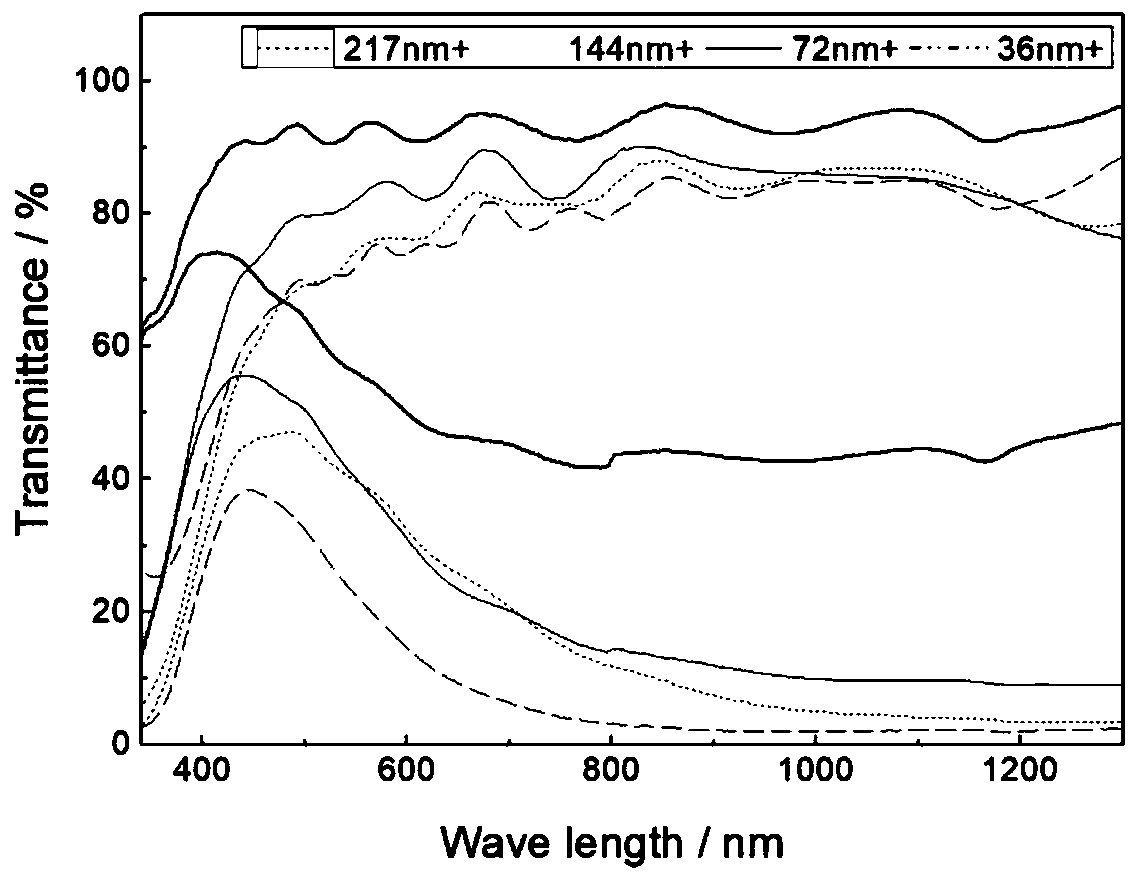

[0026] 1) Deposit a layer of tungsten oxide on the surface of clean FTO glass by DC magnetron sputtering. The parameters of DC magnetron sputtering are: the background vacuum is lower than 6×10 -4 Pa, room temperature, sputtering power 70W, working pressure 0.6Pa, Ar:O 2 =20:3, sputtering thickness is 36nm; air annealing at 400°C for 30min to form dense WO 3 monoclinic crystal;

[0027] 2) Weigh 0.04g WCl with an electronic balance 6 powder, pour it into the lining of a 50ml hydrothermal kettle and add 30ml of ethanol, stir at room temperature until it is completely dissolved, the solution gradually changes from colorless to brownish yellow, and the configuration of the precursor solution is completed; clean WO 3 / FTO is placed upside down on the support table so that WO 3 Face down, parallel to the liquid surface of the reactant, about 1mm above the liquid surface.

[0028] 3) Put on a stainless steel shell and put it in an oven, react at a constant temperature of 175°C f...

Embodiment 2

[0030] 1) Deposit a tungsten oxide layer on the surface of clean FTO glass by DC magnetron sputtering. The parameters of DC magnetron sputtering are: the background vacuum is lower than 6×10 -4 Pa, room temperature, sputtering power 70W, working pressure 0.6Pa, Ar:O 2 =20:3, the sputtering thickness is 72nm; then annealed in air at 400°C for 30min to form dense WO 3 monoclinic crystal.

[0031] 2) Use a balance to accurately weigh 0.04g WCl 6 powder, pour it into the lining of a 50ml hydrothermal kettle and add 30ml of ethanol, stir at room temperature until it is completely dissolved, the solution gradually changes from colorless to brownish yellow, and the configuration of the precursor solution is completed; clean WO 3 / FTO is placed upside down on the support table so that WO 3 Face down, parallel to the liquid surface of the reactant, about 0.5mm above the liquid surface;

[0032] 3) Put on a stainless steel shell and put it in an oven, react at a constant temperature...

Embodiment 3

[0034] 1) Deposit a layer of tungsten oxide on the surface of clean FTO glass by DC magnetron sputtering method; the parameters of DC magnetron sputtering are: the background vacuum is lower than 6×10 -4 Pa, room temperature, sputtering power 70W, working pressure 0.6Pa, Ar:O 2 =20:3, the sputtering thickness is 144nm, and then annealed at 400°C for 30min in air to form dense WO 3 monoclinic crystal.

[0035] 2) Use a balance to accurately weigh 0.04g WCl 6 powder, pour it into the lining of a 50ml hydrothermal kettle and add 30ml of ethanol, stir at room temperature until it is completely dissolved, the solution gradually changes from colorless to brownish yellow, and the configuration of the precursor solution is completed; clean WO 3 / FTO placed upside down on the support table, WO 3 Face down, parallel to the liquid surface of the reactant, about 3mm above the liquid surface.

[0036] 3) Put on a stainless steel shell and put it in an oven, react at a constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coloring efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com