Nano ultrahigh-strength concrete with high impact resistance

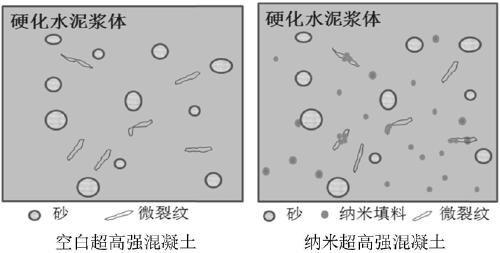

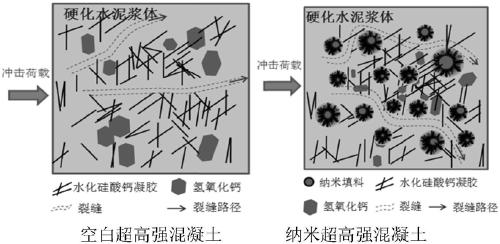

A technology of ultra-high-strength concrete and high impact resistance, applied in the field of building materials, can solve the problem of fiber dispersion, the problem of concrete viscosity has not been well solved, etc., to reduce initial defects, improve weak interface performance, and improve deformation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0039] Table 1 Raw materials and parts by weight thereof

[0040]

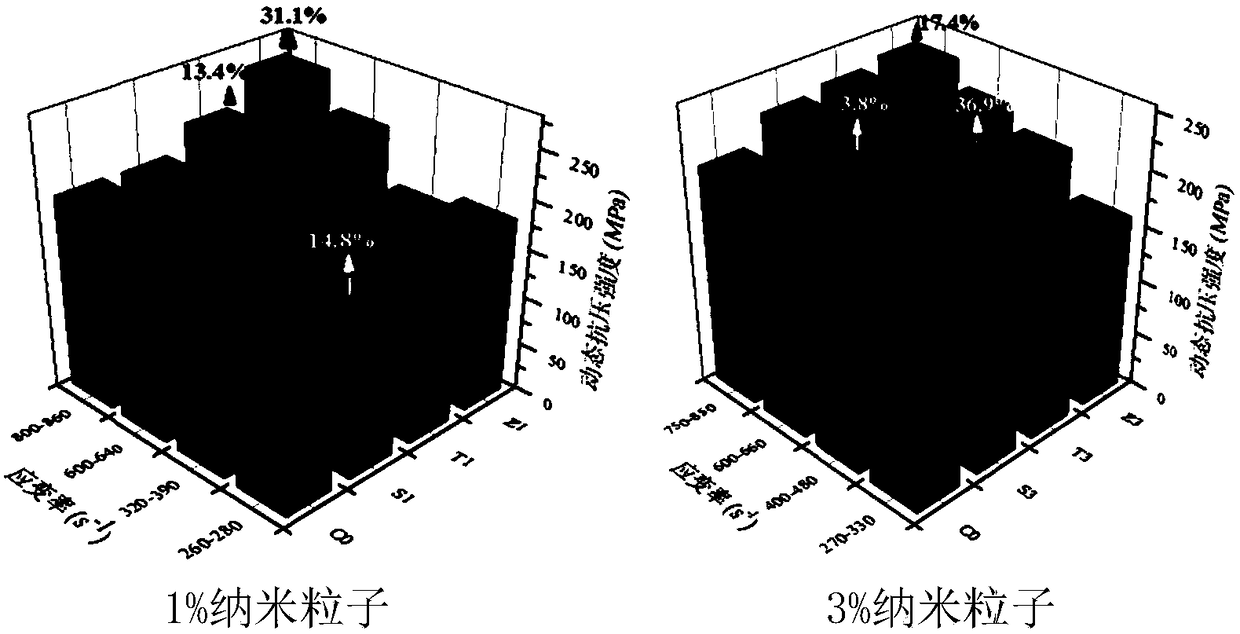

[0041]Dynamic impact resistance to pressure performance: The impact compression test is carried out using a conventional separate Hopkinson (SHPB) device, and the test block size is a cylinder of Φ15.0mm×30.0mm. The three-wave method formula is used to process the collected waveforms, and the dynamic compressive strength is recorded as the dynamic strength performance of concrete; the peak strain and ultimate strain under the corresponding peak stress are recorded to reflect the deformation capacity of concrete. The impact toughness index is obtained by integrating the stress-strain curve, which is used to characterize the ability of the microwire composite RPC to absorb energy from loading to complete destruction; and the specific energy absorption is calculated by the formula, which characterizes the ability of the material to dissipate the stress wave energy per unit volume size.

[0042] Depend on im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com