Gas phase method polypropylene production method

A production method and technology of polypropylene, applied in the field of olefin polymerization, can solve problems such as temperature fluctuation, poor heat transfer capacity, and low density of gas phase reaction medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

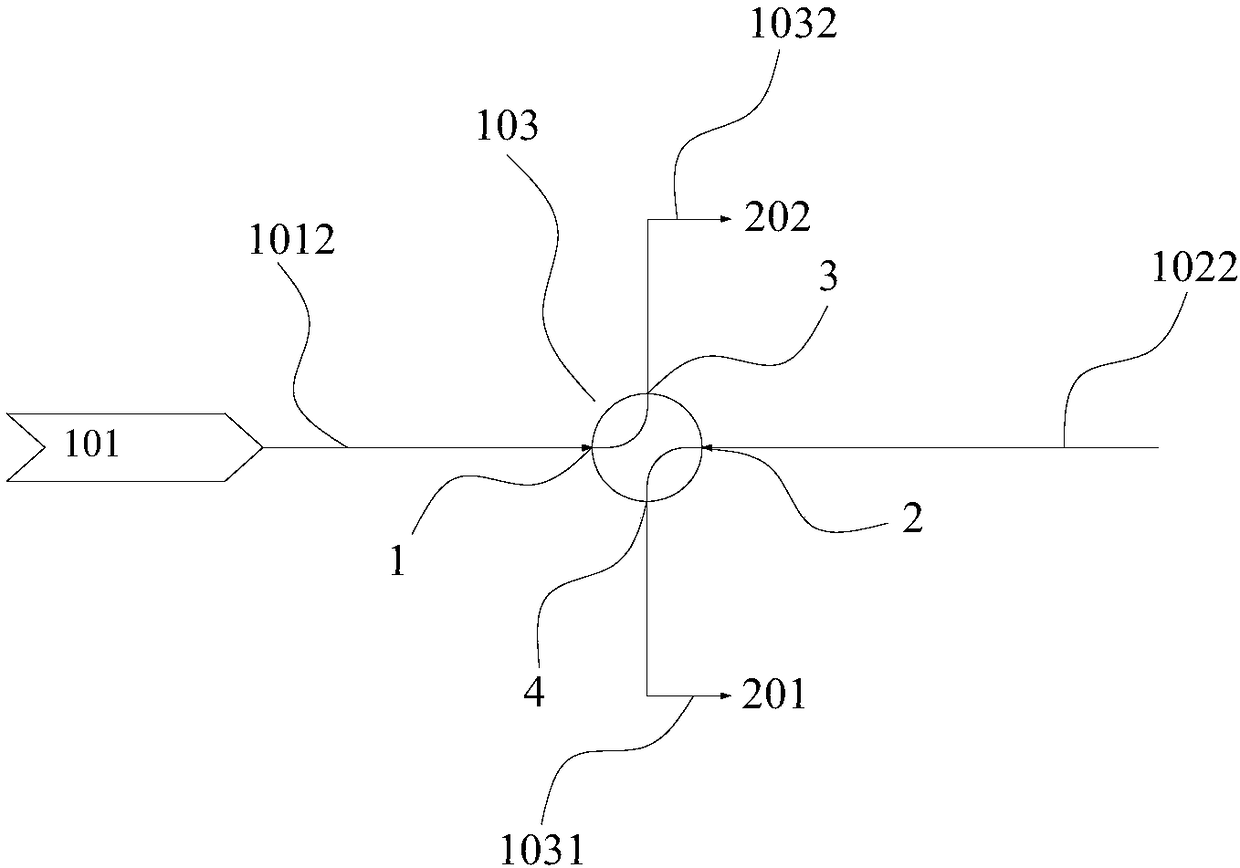

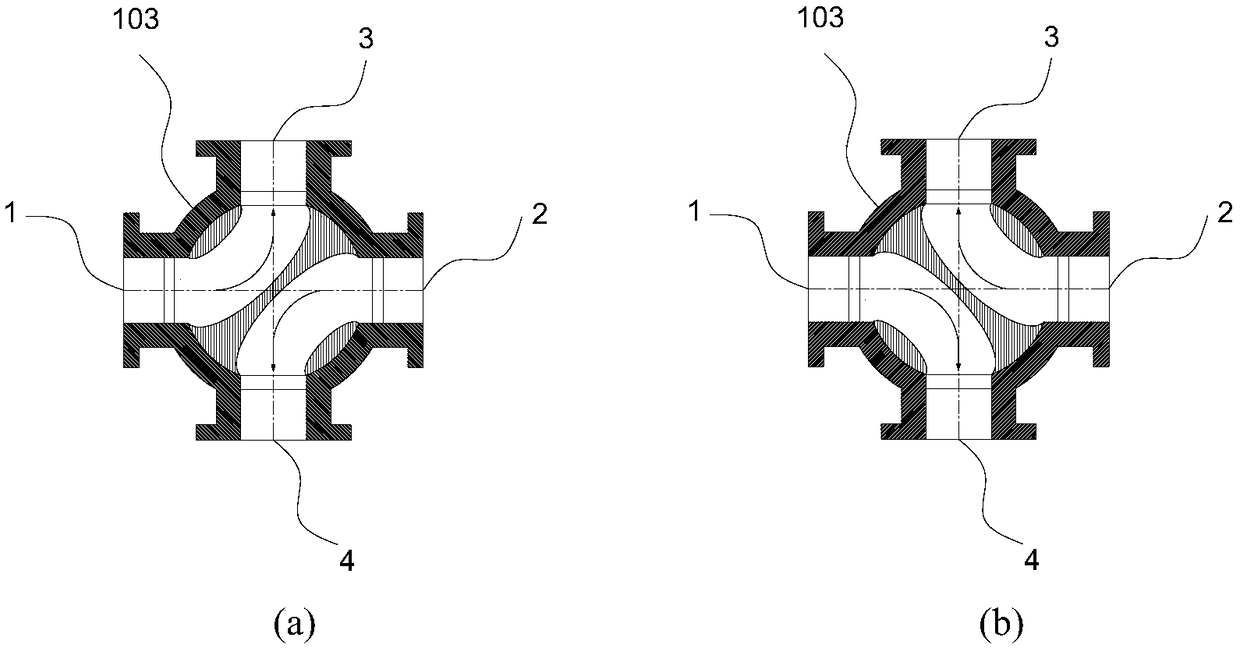

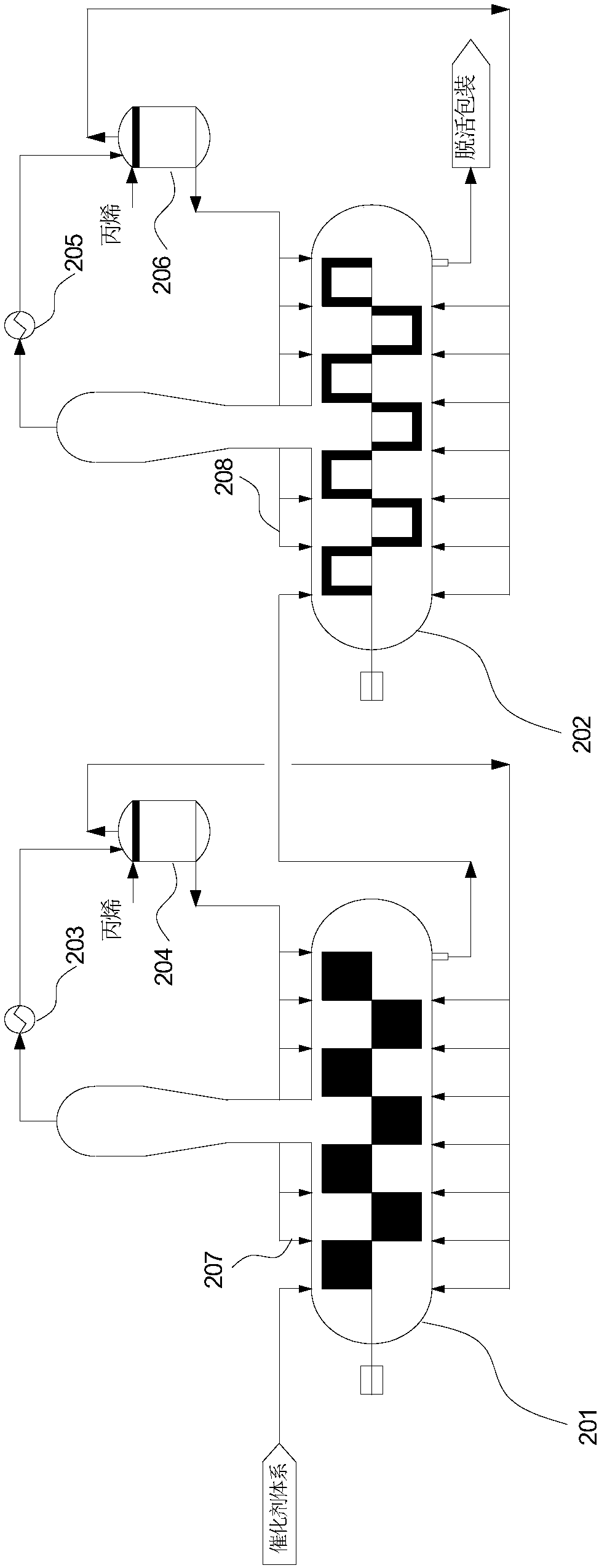

[0087] The 200,000 tons / year Innovene process polypropylene production line adopts double-horizontal gas-phase stirred bed reactors. Its process is based on the existing gas-phase polypropylene production process of Comparative Example 1, adding a liquid-phase bulk pre-polymerization device and a pre-polymerization material distribution system. Its flow chart is as Figure 4 shown.

[0088] The prepolymerization method of propylene is continuous liquid phase bulk prepolymerization. The pre-polymerization reactor 101 is a loop reactor, and the materials in the reactor are moved at a high speed through an axial flow pump to enhance heat transfer. The heat of polymerization is withdrawn by the cryogenic liquid propylene feed and chilled water in the jacket of the prepolymerization reactor 101 . Among them, the low-temperature liquid propylene is the raw material propylene cooled to 10°C by the heat exchanger 102, and then divided into two streams, the propylene passing through...

Embodiment 2

[0093] The 200,000 tons / year Innovene process polypropylene production line adopts double-horizontal gas-phase stirred bed reactors. Based on the existing gas-phase polypropylene production process of Comparative Example 1, the flow process adds a liquid-phase bulk prepolymerization device, a prepolymerization material distribution system, and a pipeline 2012 from the first gas-phase reactor 201 to the deactivation packaging section. Flowchart such as Figure 5 shown.

[0094] The prepolymerization mode, prepolymerization conditions, and prepolymerization material distribution system of propylene are the same as in Example 1. The switching cycle time T of the four-way ball valve set by the program software in the pre-polymerization material distribution system is 6 minutes, and the time T of the A state A is 3 minutes, the time T of state B B for 3 minutes.

[0095] Through the pre-polymerization material distribution system, the pre-polymerization material is divided into...

Embodiment 3

[0102] The 200,000 tons / year Novolen process polypropylene production line adopts double vertical gas phase stirred bed reactors. Its flow process has increased liquid phase bulk prepolymerization device and prepolymerization material distribution system on the basis of the existing gas phase polypropylene production technological process of comparative example 2, and its flow chart is as follows Figure 7 shown.

[0103] The prepolymerization method of propylene is continuous liquid phase bulk prepolymerization. The pre-polymerization reactor 101 is a loop reactor, and the materials in the reactor are moved at a high speed through an axial flow pump to enhance heat transfer. The heat of polymerization is withdrawn by the cryogenic liquid propylene feed and chilled water in the jacket of the prepolymerization reactor 101 . Among them, the low-temperature liquid propylene is the raw material propylene cooled to 10°C by the heat exchanger 102, and then divided into two streams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com