Dust-suppression anti-freezing liquid for railway coal transportation

An antifreeze, coal technology, applied in the directions of dust prevention, fire prevention, safety devices, etc., can solve problems such as low use efficiency, achieve and block decomposition and volatilization, increase dust suppression function, and improve the effect of use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A dust-suppressing antifreeze solution for railway coal transportation, which comprises by weight: 40 parts of anhydrous calcium chloride; 4 parts of magnesium hexafluorosilicate; 9 parts of ethylene glycol; 15 parts of glycerin; 5 parts of hydroxypropyl methylcellulose ; Preservatives 2 parts. Wherein, the preservative includes: 1 part of triethanolamine; 0.3 part of benzotriazole; and 0.7 part of sodium silicate.

[0033] The preparation method of railway coal transportation dust suppression antifreeze described in the present embodiment comprises:

[0034] Step 1: Add specified weight parts of benzotriazole and sodium silicate to pure water, and stir until they are completely dissolved in pure water;

[0035] Step 2: Add specified parts by weight of anhydrous calcium chloride and magnesium hexafluorosilicate to the solution in Step 1 and stir until they are completely dissolved;

[0036] Step 3: Add specified weight parts of ethylene glycol, glycerol and triethanol...

Embodiment 2

[0040] A dust-suppressing antifreeze solution for railway coal transportation, which comprises by weight: 45 parts of anhydrous calcium chloride; 6 parts of magnesium hexafluorosilicate; 16 parts of ethylene glycol; 20 parts of glycerin; 12 parts of hydroxypropyl methylcellulose ; 6 parts of preservatives. Wherein, the preservative includes by weight: 3.2 parts of triethanolamine; 1.6 parts of benzotriazole; and 1.2 parts of sodium silicate.

[0041] The preparation method of the dust-suppressing antifreeze for railway coal transportation described in this embodiment is the same as the preparation method in Embodiment 1.

Embodiment 3

[0043] A dust-suppressing antifreeze liquid for railway coal transportation, which comprises by weight: 42 parts of anhydrous calcium chloride; 5 parts of magnesium hexafluorosilicate; 13 parts of ethylene glycol; 17 parts of glycerin; 9 parts of hydroxypropyl methylcellulose ; Preservatives 4 parts. Wherein, the preservative includes by weight: 1.8 parts of triethanolamine; 1.5 parts of benzotriazole; and 0.7 parts of sodium silicate.

[0044] The preparation method of the dust-suppressing antifreeze for railway coal transportation described in this embodiment is the same as the preparation method in Embodiment 1.

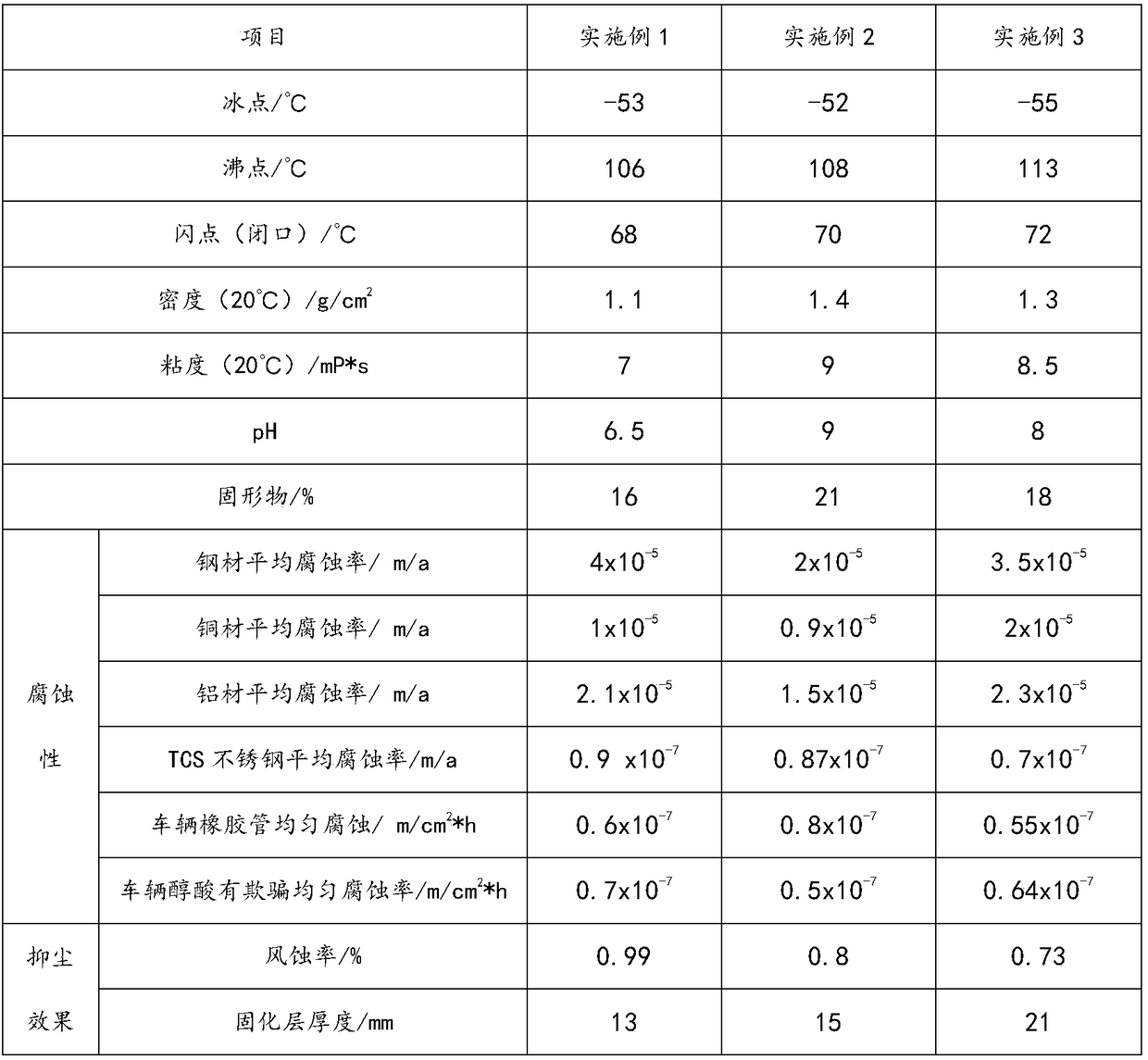

[0045] After testing, the various parameters of the railway coal transportation dust suppression antifreeze liquid prepared by the above three embodiments are as shown in Table 1:

[0046] Table 1 Parameters of dust suppression antifreeze fluid for railway coal transportation

[0047]

[0048] According to Table 1, it can be concluded that in the actual use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com