High-temperature vacuum evaporation and ionization film coating device and operating method thereof

A high-temperature vacuum and coating device technology, which is applied in vacuum evaporation coating, ion implantation coating, sputtering coating, etc., to achieve the effect of increasing the applicable field, saving electric energy and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

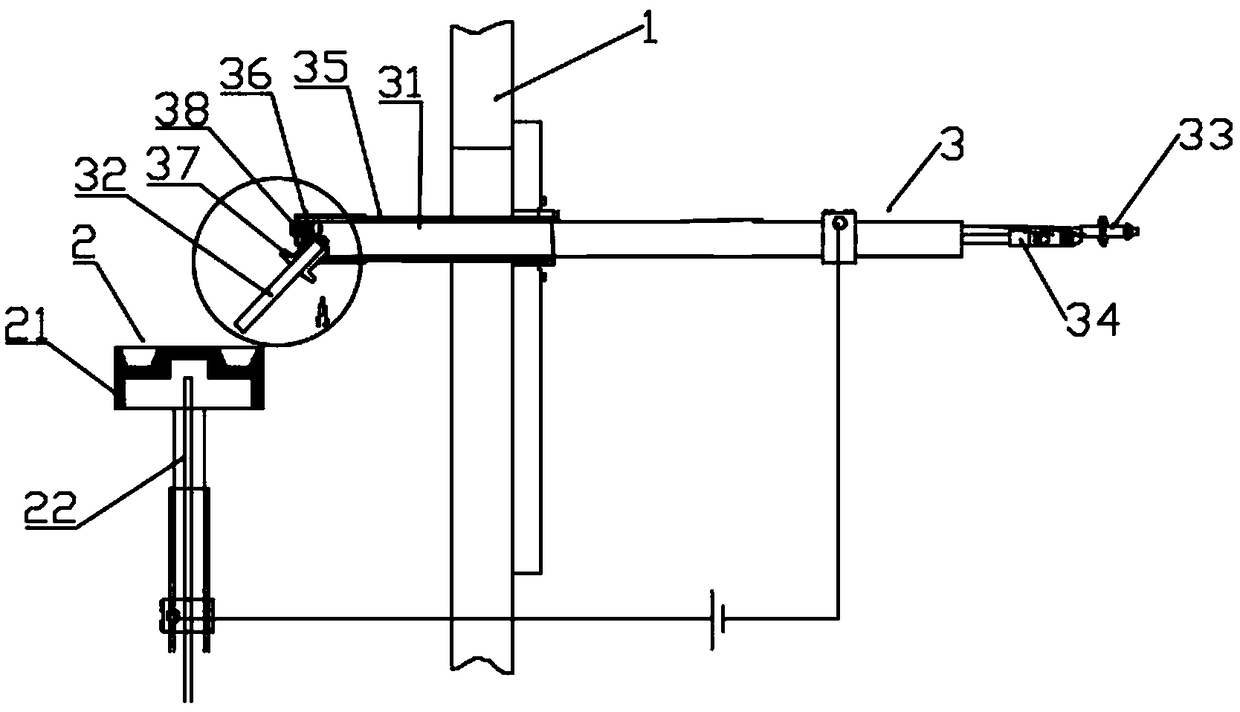

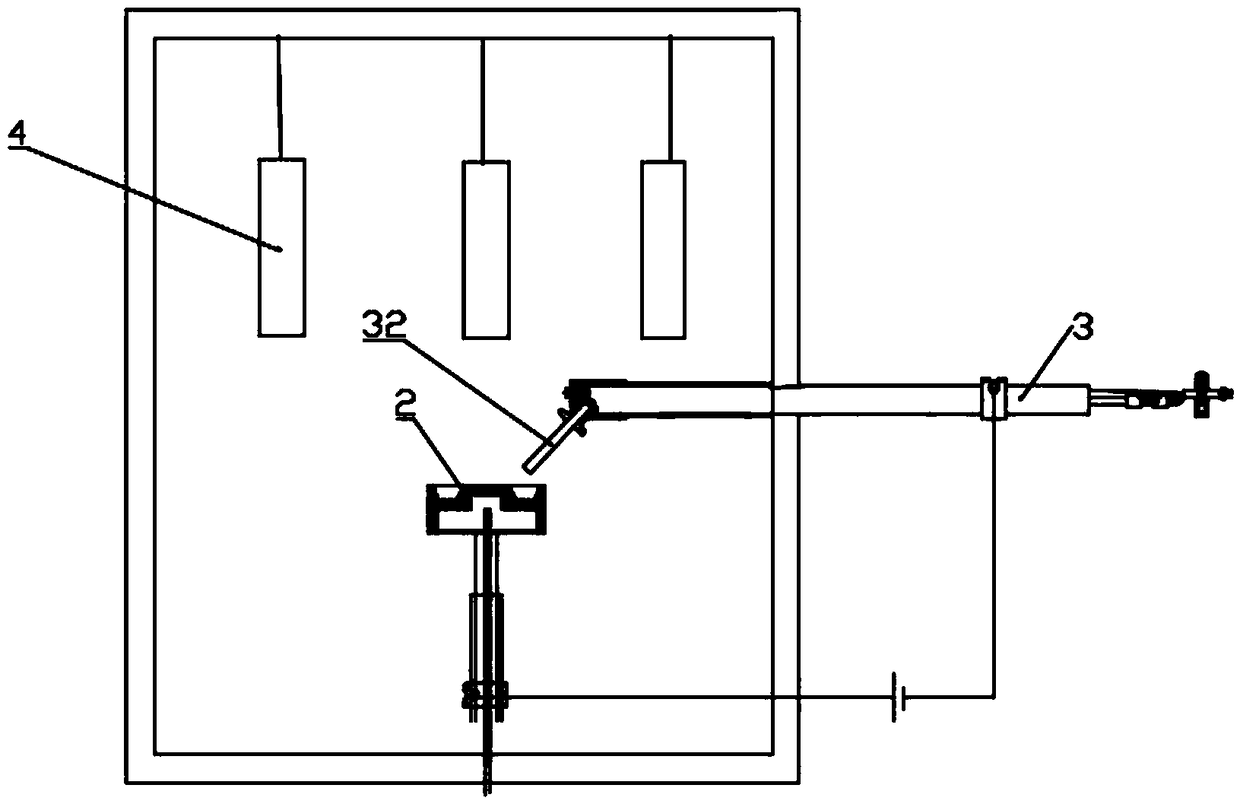

[0030] Such as Figure 1-3 As shown, the high-temperature vacuum evaporation ionization coating device includes a high-temperature vacuum-sealed body of furnace 1, and the inside of the body of furnace 1 is hung with parts 4 to be coated such as tools, metals, molds, etc. to be coated; the bottom of the parts 4 to be coated An evaporation source 2 is provided, and the inside of the evaporation source 2 is equipped with a plated metal. The furnace body of the furnace body 1 is provided with an electron gun 3 whose end extends into the interior of the furnace body 1, and the electron beam emitted by the electron gun 3 is injected into the evaporation source 2 to evaporate the coating metal;

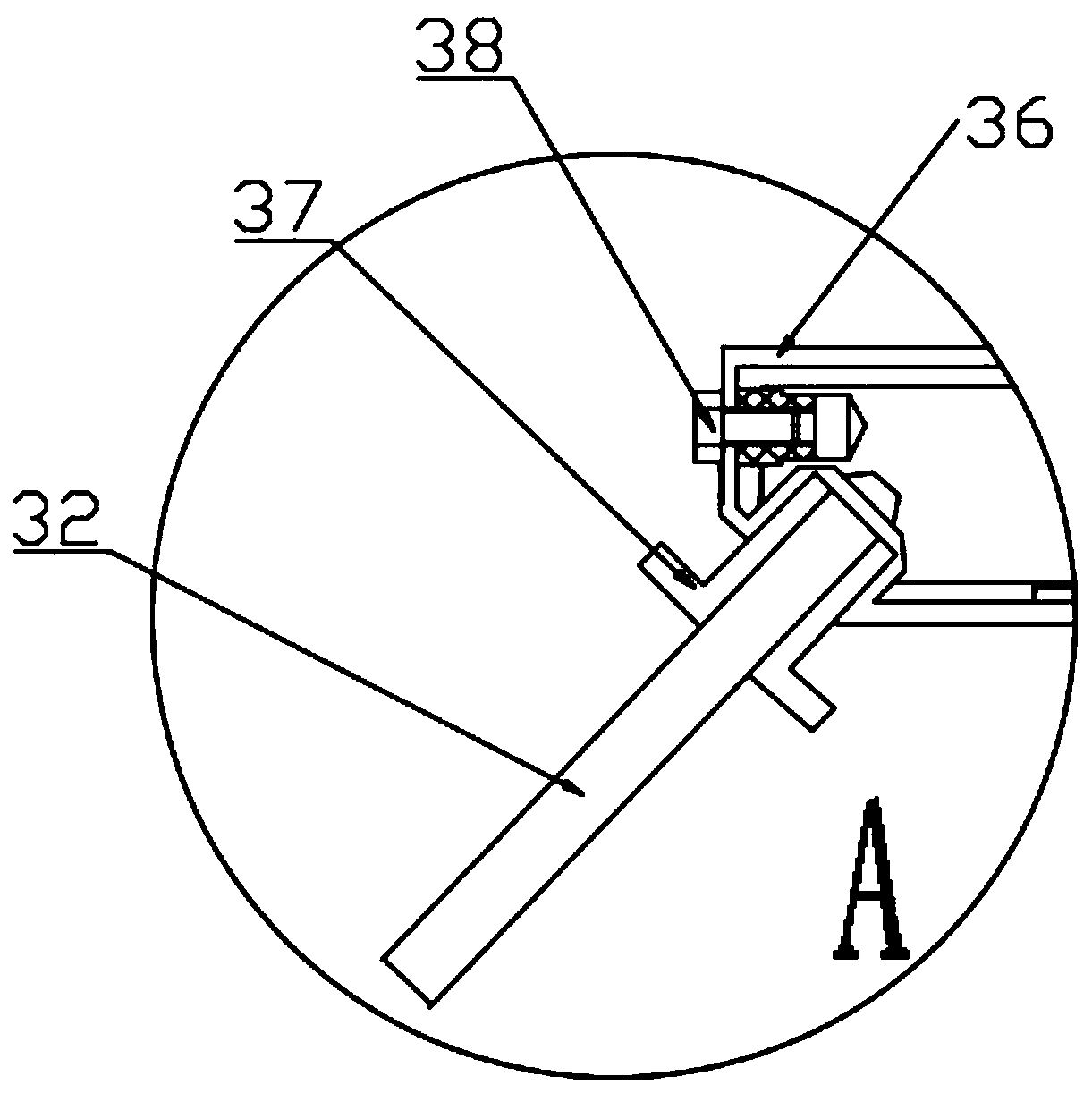

[0031] The electron gun 3 includes a metal sleeve 31 and a hollow tantalum tube 32 capable of self-sustaining discharge; one end of the hollow tantalum tube 32 is conductively connected to the end of the metal sleeve 31 through a fixed lock nut 37 made of molybdenum metal material, and the ...

Embodiment 2

[0033] On the basis of Embodiment 1, the pipe body of the metal sleeve 31 is provided with an insulating sleeve 35 for insulation between the metal sleeve 31 and the furnace body 1, and the end of the metal sleeve 31 located inside the furnace body 1 A protective sleeve 36 not in contact with the metal sleeve 31 is provided. The metal sleeve 31 is made of copper; the gas conduit 33 is made of copper; the hollow tantalum tube 32 is a hollow tantalum tube; the evaporation source 2 is a crucible 21 loaded with at least one coating metal ; The insulating sleeve 35 is a glass tube; the protective sleeve 36 is made of metallic copper.

Embodiment 3

[0035] On the basis of Embodiment 1, a cooling circuit 34 parallel to the gas duct 33 is also provided in the metal sleeve 31 . The cooling circuit 34 is used for cooling to prevent the damage of the electron gun 3 caused by the breakdown of the metal conduit caused by the internal temperature; cooling to prevent the constituent metals of the crucible 21 from evaporating and causing damage to the crucible 21 .

[0036] The junction of the electron gun 3 and the furnace body 1 or the front and rear adjacent areas of the junction are provided with a sealed structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com