Method for preparing biomechanical pulp from wheat straw sheath

A technology of mechanical pulp and grass blades, applied in non-woody plant/crop pulp, using microorganism/enzymatic cellulose treatment, textiles and papermaking, etc., can solve the problem of reducing the utilization rate of wheat straw raw materials, increasing the cost of material preparation, and fiber water absorption and swelling and fine fibrillation difficulties, etc., to achieve good prospects for industrial application, improve the utilization rate of wheat straw, and the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

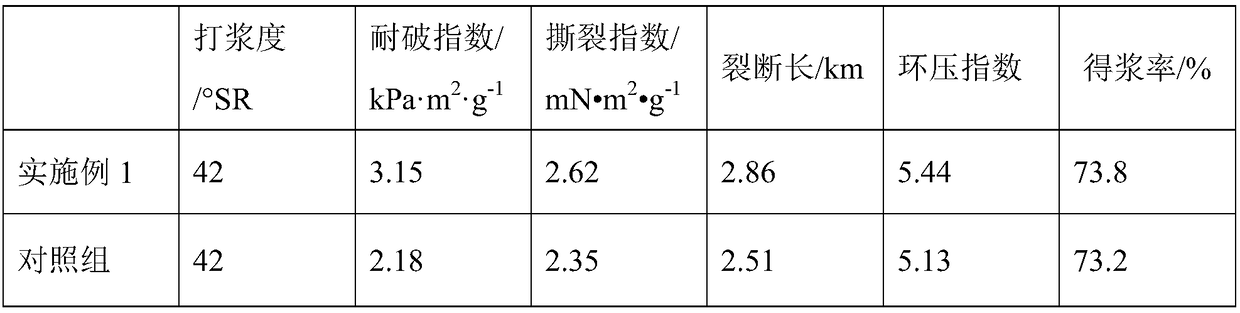

Embodiment 1

[0038] A method for preparing biomechanical pulp from wheat straw sheaths, the implementation case prepares biomechanical pulp, and tests its pulping performance.

[0039] (1) The air-dried wheatgrass leaf sheath after physical selection and dedusting is cut into 3cm long standby raw materials.

[0040] (2) Put the spare raw materials into a normal temperature processor or reactor, and treat the wheat grass leaf sheath with warm water and alkaline compound enzyme according to the liquid ratio of 1:5. During the treatment, adjust the pH value with NaOH to make the wheat grass leaf sheath The pH value of the water is 8, the treatment time is controlled at 90min, and the temperature is at 50°C. The alkaline biological enzyme is a compound enzyme of xylanase, cellulase and pectinase. The total dosage is: 50IU / mL, the enzyme activity ratio of xylanase, cellulase and pectinase is 3:1:1.

[0041] (3) When the wheat grass leaf sheath reaches a certain degree of softening, take out the...

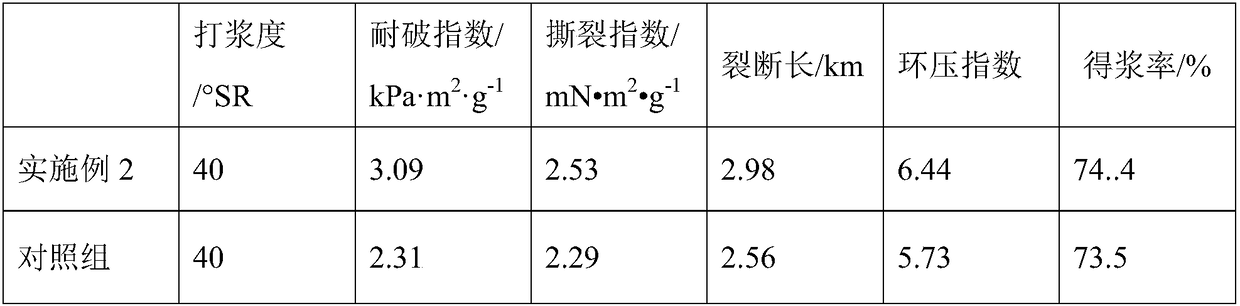

Embodiment 2

[0048] A method for preparing biomechanical pulp from wheat straw sheaths, the implementation case prepares biomechanical pulp, and tests its pulping performance.

[0049] (1) The air-dried wheatgrass leaf sheath after physical selection and dedusting is cut into 4cm long standby raw materials.

[0050] (2) Put the spare raw materials into a normal temperature processor or reactor, and treat the wheat grass leaf sheath with warm water and alkaline compound enzyme according to the liquid ratio of 1:4. During the treatment, adjust the pH value with NaOH to make the wheat grass leaf sheath The pH value of the water is 9, the treatment time is controlled at 70min, and the temperature is 55°C. The alkaline biological enzyme is a compound enzyme of xylanase, cellulase and pectinase. The total dosage is: 40IU / mL , the enzyme activity ratio of xylanase, cellulase and pectinase is 5:2:1.

[0051] (3) When the wheatgrass sheath reaches a certain degree of softening, take out the wheatg...

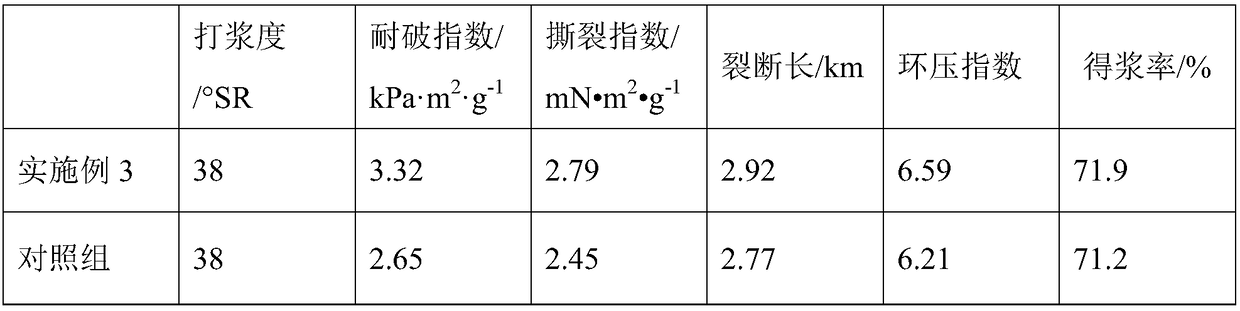

Embodiment 3

[0058] A method for preparing biomechanical pulp from wheat straw sheaths, the implementation case prepares biomechanical pulp, and tests its pulping performance.

[0059] (1) The air-dried wheatgrass leaf sheath after physical selection and dedusting is cut into 5cm long standby raw materials.

[0060] (2) Put the spare raw materials into the normal temperature processor or reactor, and treat the wheat grass leaf sheath with warm water and alkaline compound enzyme according to the liquid ratio of 1:6. During the treatment, adjust the pH value with NaOH to make the wheat grass leaf sheath The pH value of the water is 8, the treatment time is controlled at 60min, and the temperature is 50°C; the alkaline biological enzyme is a compound enzyme of xylanase, cellulase and pectinase, and the total dosage is: 40IU / mL , the enzyme activity ratio of xylanase, cellulase and pectinase is 2:1:1.

[0061] (3) When the wheat straw sheath reaches a certain degree of softening, take out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com