Bus lifting device

A technology for buses and vehicle-carrying platforms, which is applied to buildings, building types, buildings, etc. where cars are parked. It can solve the problems that the lifting device cannot meet the requirements and the mass of the bus is large, and achieve the effect of small space occupation and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

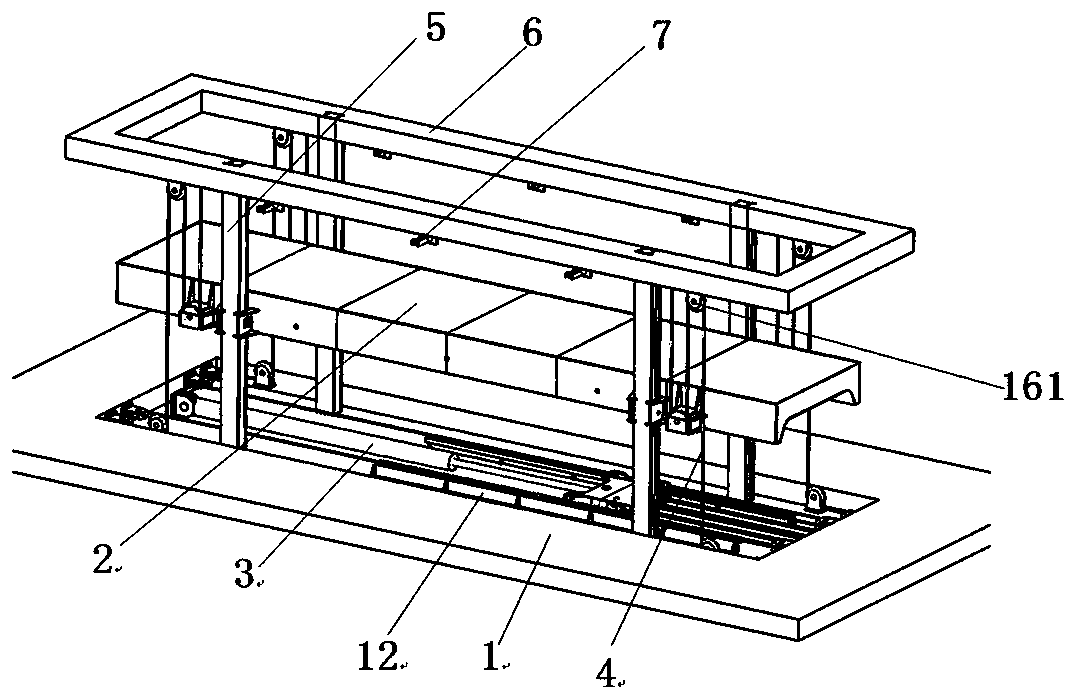

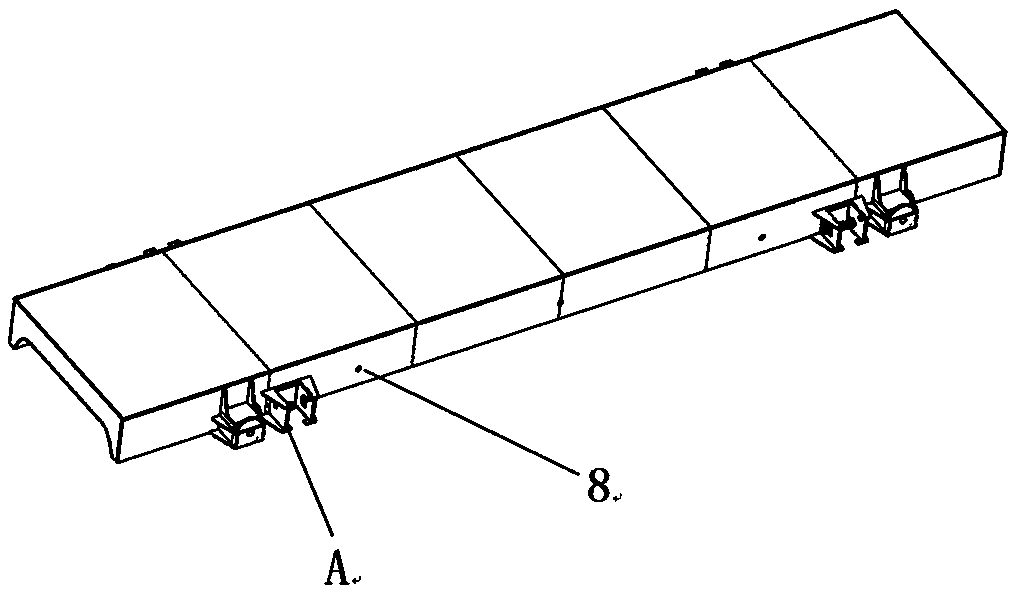

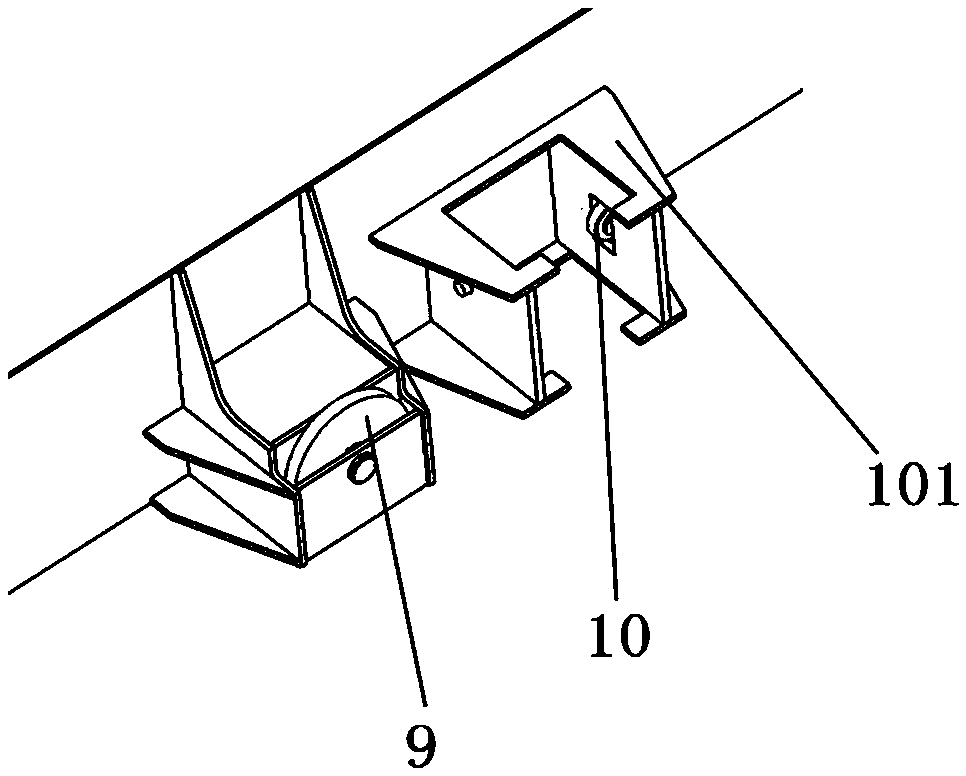

[0024] What the present invention provides is a kind of bus hoisting device, and this device is used for the three-dimensional garage of bus, comprises the ground layer as bottom layer 1, and the second floor frame 6 is supported by lifting guide column 5 on the ground layer, in order to ensure support Stable, set at least four lifting guide columns, such as figure 1 Shown is the structure of the lifting device with four lifting guide columns. The four structures are stable structures, which can limit the horizontal shaking of the following lifting vehicle platform during the ascent process. In order to improve safety considerations, also More than four lifting guide columns 5 can be set.

[0025] In the space between a plurality of lifting guide columns 6, a lifting vehicle-carrying platform 2 is set, and the second-floor frame 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com