Hydraulic abdomen lifting oil cylinder

A technology for lifting oil cylinders and hydraulic oil, which is applied in the field of hydraulic oil cylinders, and can solve problems such as loss of efficacy, affecting the working efficiency of oil cylinders, and large leakage, and achieves the effects of improving quality, ensuring sealing, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

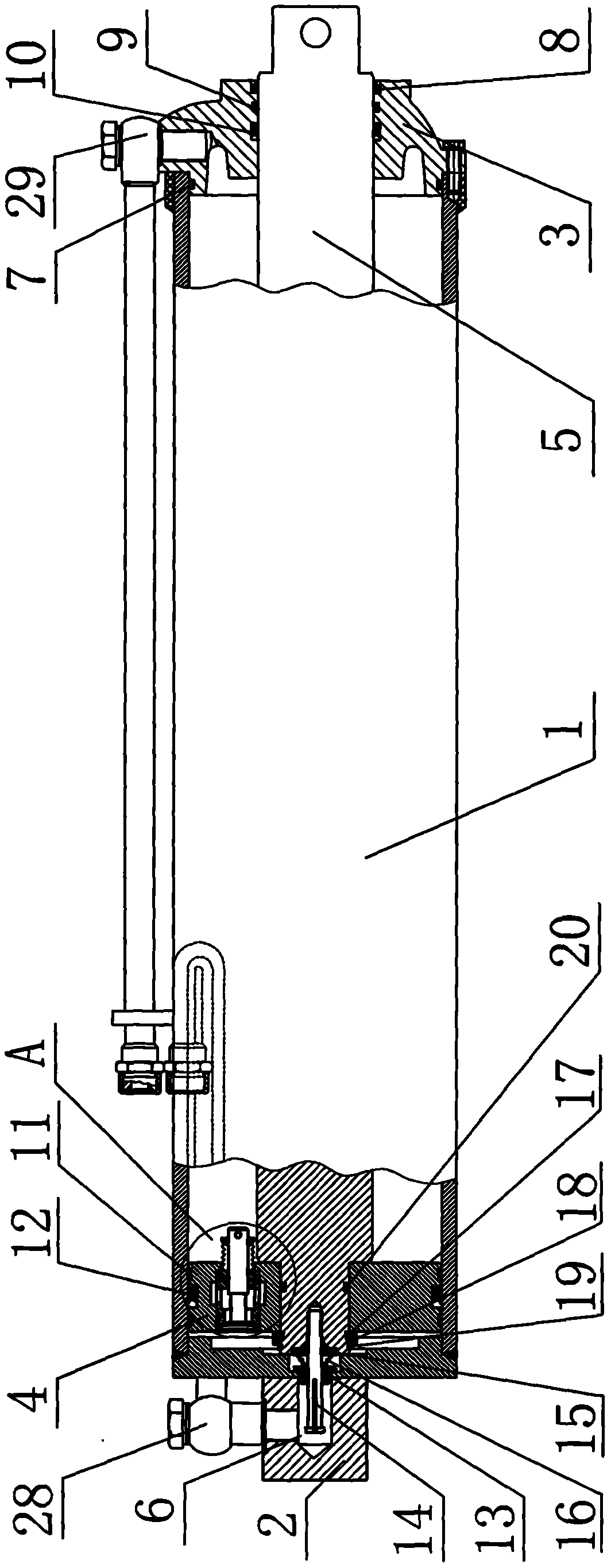

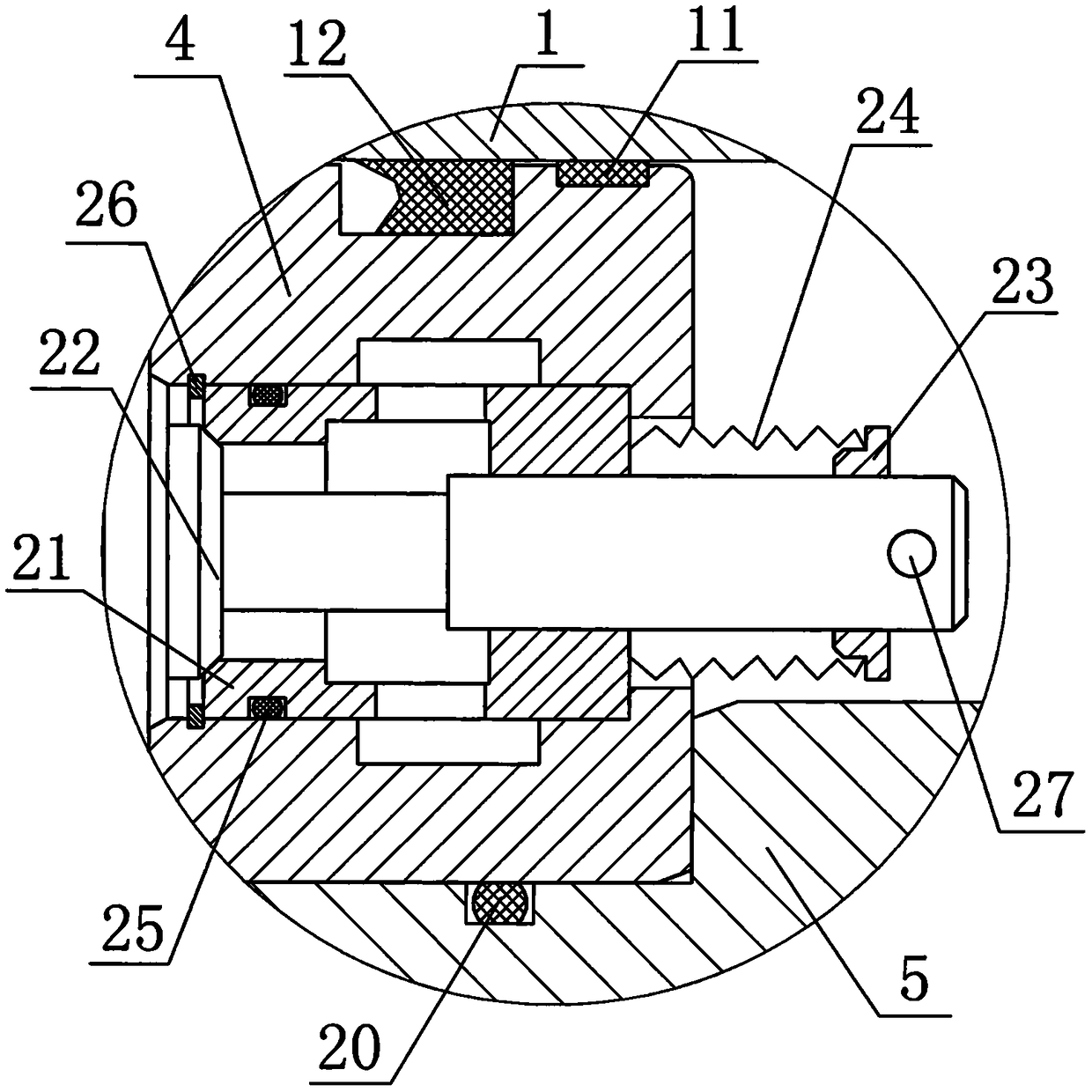

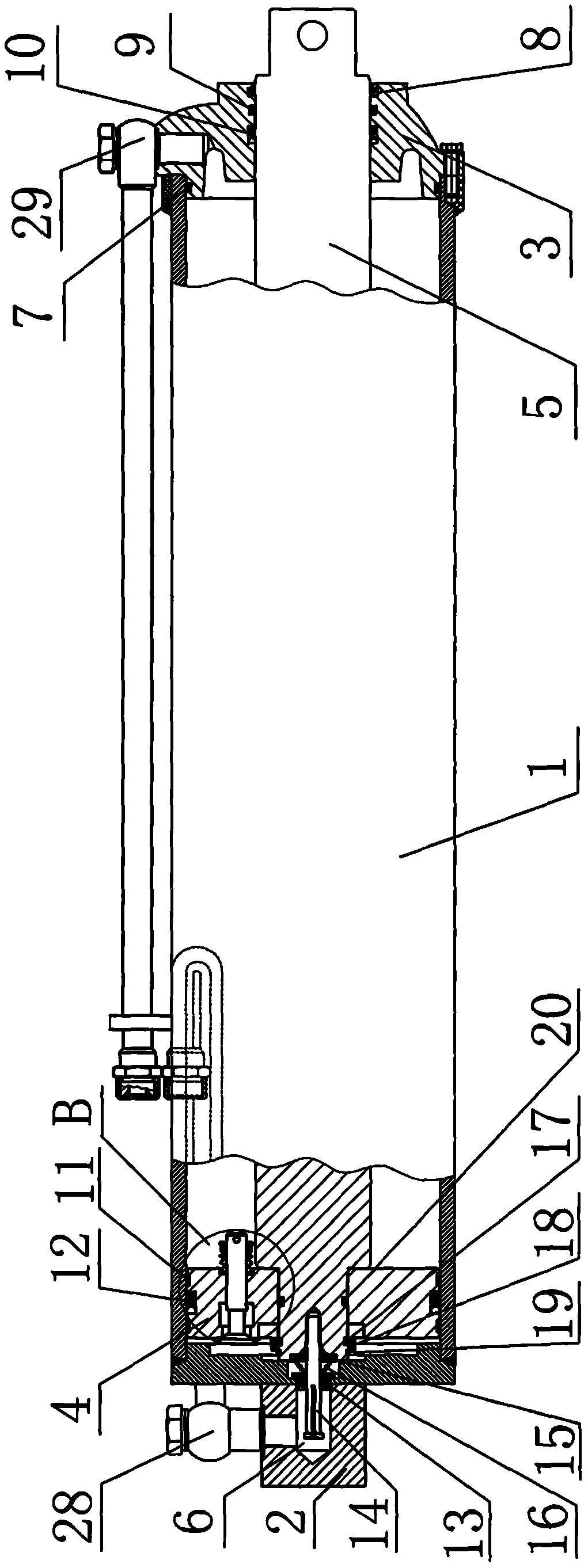

[0017] Reference Figure 1-Figure 2 The hydraulic abdominal lifting cylinder described in this embodiment includes a cylinder block 1, a cylinder bottom 2, a cylinder head 3, and a piston 4 and a piston rod 5 arranged in the inner cavity of the cylinder block 1. among them:

[0018] The cylinder bottom 2 is welded to the bottom end of the cylinder block 1, and a hydraulic oil channel 6 is provided in the cylinder bottom 2, and the hydraulic oil channel 6 communicates with the inner cavity of the cylinder block 1. The cylinder bottom 2 is provided with an oil inlet, and an oil inlet pipe welding piece 28 is connected to the oil inlet, and the oil inlet pipe welding piece 28 communicates with the hydraulic oil channel 6.

[0019] The cylinder head 3 is fixedly installed on the top end of the cylinder block 1 by bolts, and a first O-ring seal 7 is provided between the cylinder head 3 and the cylinder block 1. The cylinder head 3 is provided with an oil outlet, and an oil outlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com