A logistics network optimization method based on hybrid automata

A hybrid automaton and logistics network technology, applied in logistics, instruments, data processing applications, etc., can solve the problems of limiting production profits and maximizing the comprehensive benefits of production characteristics and performance, modeling complexity, and difficult solutions, to achieve comprehensive benefit-maximizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

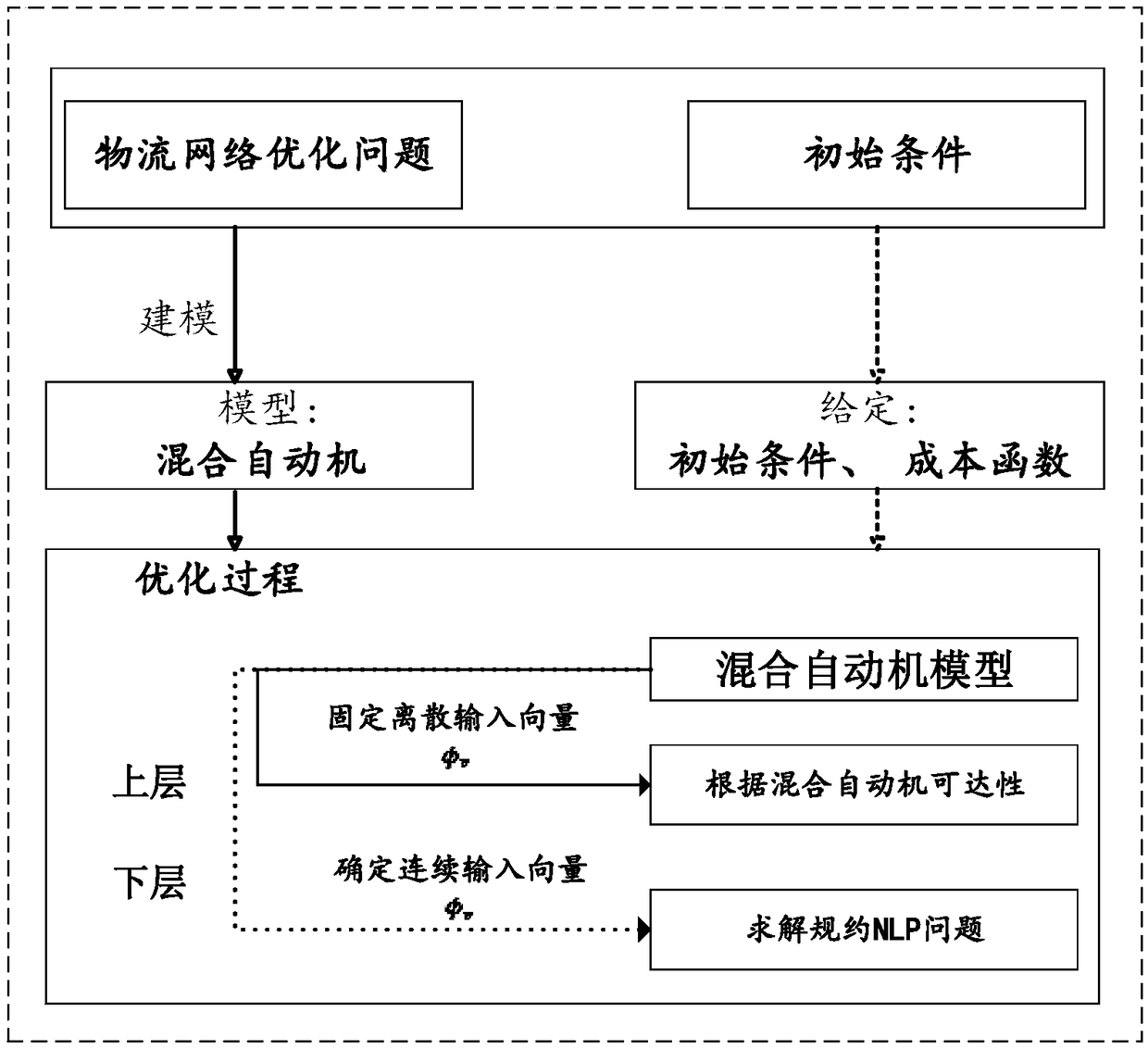

[0035] The invention relates to a logistics network optimization method based on a hybrid automaton, which comprises the following steps:

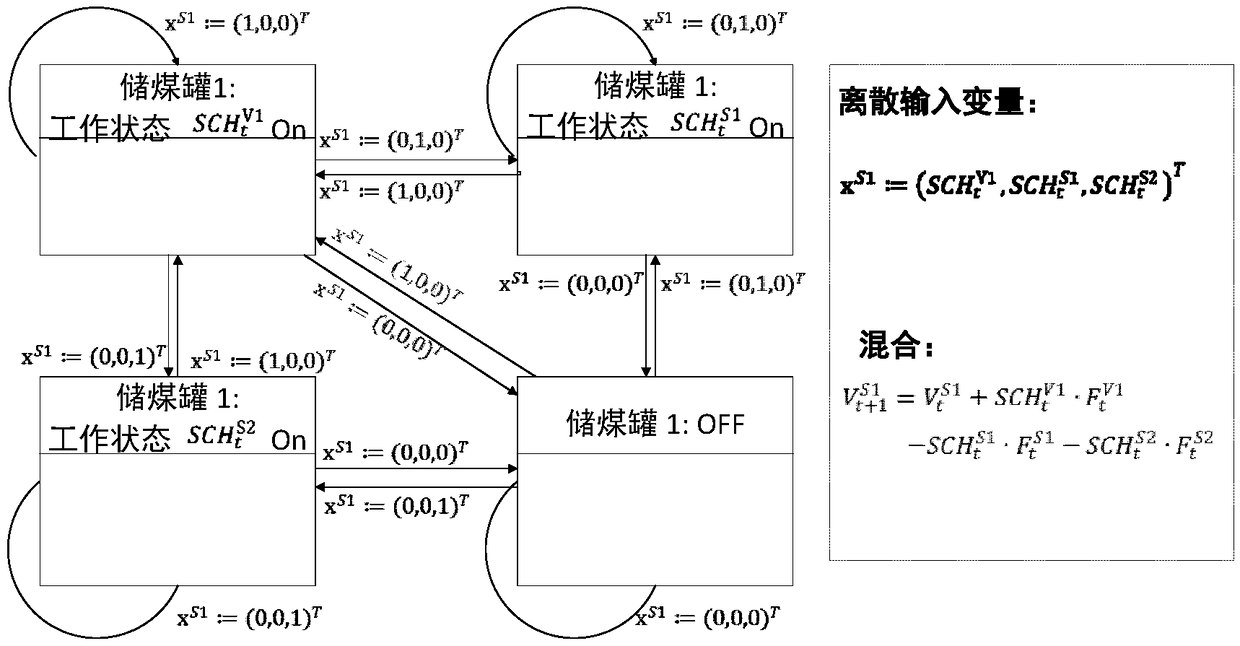

[0036] Step 1. Construct the hybrid automata model of the devices in the logistics network.

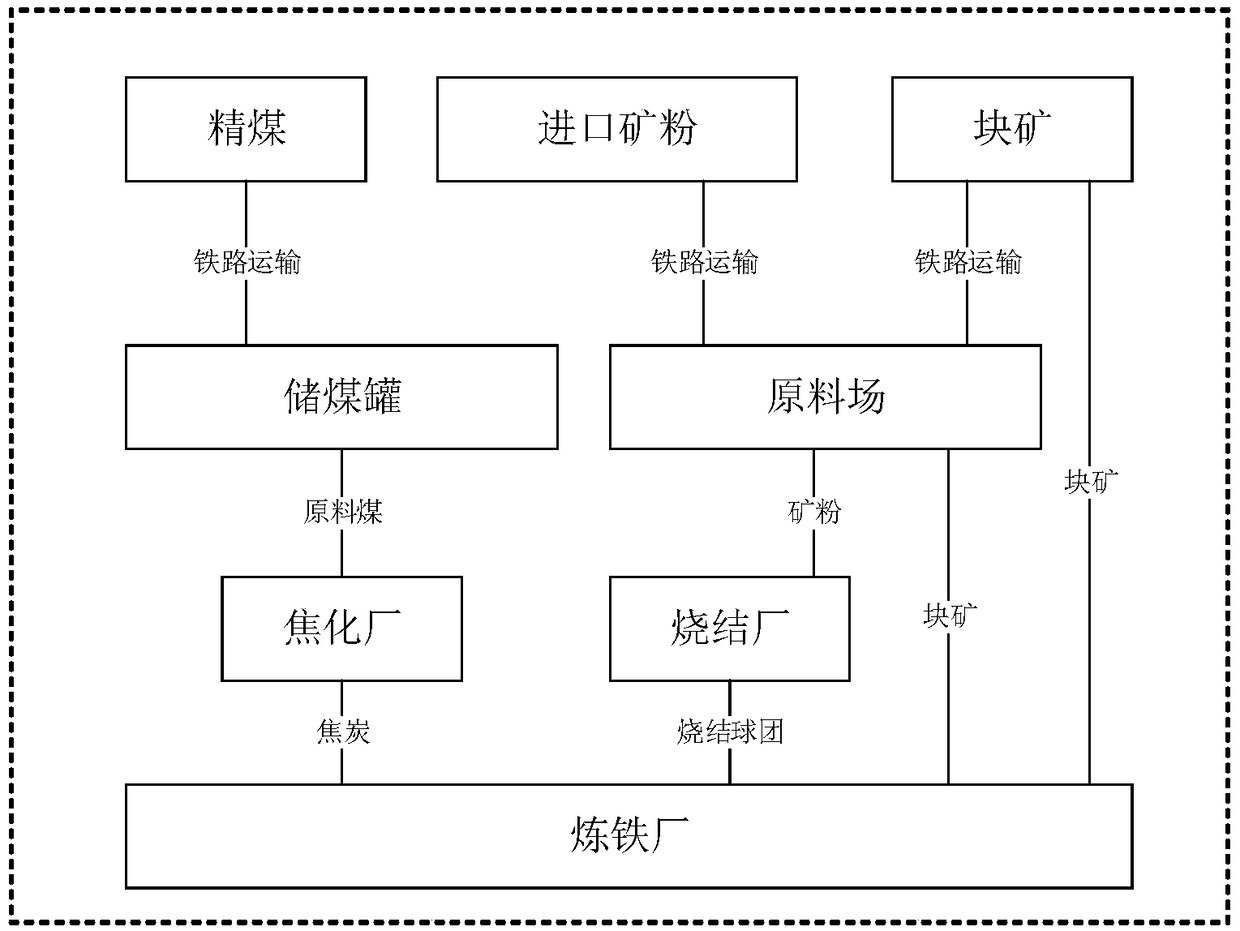

[0037] In the logistics network of a steel company, the scheduling events include the scheduling start time, starting point, and end point. These variables are all discrete variables. The scheduled fuel quantity in the scheduled event is a continuous variable. Therefore, the logistics optimization scheduling process is a mixed process, and a mixed model needs to be established. That is, a hybrid automata model is constructed for the devices in the logistics optimization network under a certain period of time, such as coal storage tanks and raw material tanks, and then the device model is extended to the entire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com