A method for detecting fiber distribution in mixed fiber products

A technology of mixed fibers and detection methods, which is applied in image analysis, measurement devices, analysis materials, etc., can solve problems such as the inability to intuitively reflect the distribution of mixed fiber webs, and the inability to evaluate the uniformity of fiber webs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Taking glass fiber / polyester fiber mixed fiber mesh products as an example, the fiber ratio and grouping are shown in Table 1 to illustrate the feasibility of this method.

[0038] Table 1

[0039]

[0040] First, use the image collector to randomly collect the fiber web image made of the fourth group of mixed fiber ratios in Table 1, with a pixel size of 3000 pixels × 4000 pixels (such as figure 2 shown), the collected image is denoised and grayscaled using Sobel filter method and weighted average method (such as image 3 shown).

[0041] Due to the difference in light sensitivity between glass fiber and polyester fiber, using this feature, figure 2 The white part is glass fiber, and the black part is polyester fiber. In this paper, glass fiber is set as the target fiber and polyester fiber is set as the non-target fiber according to the actual needs of the project.

[0042] First, use Matlab to invert and reduce the order of the collected original image, the r...

Embodiment 2

[0047] In order to prove that this patent can be applied to other types of mixed fiber products, this paper also takes basalt fiber / polyester fiber mixed fiber mesh products as an example, and the fiber ratio and grouping are shown in Table 2.

[0048] Table 2

[0049]

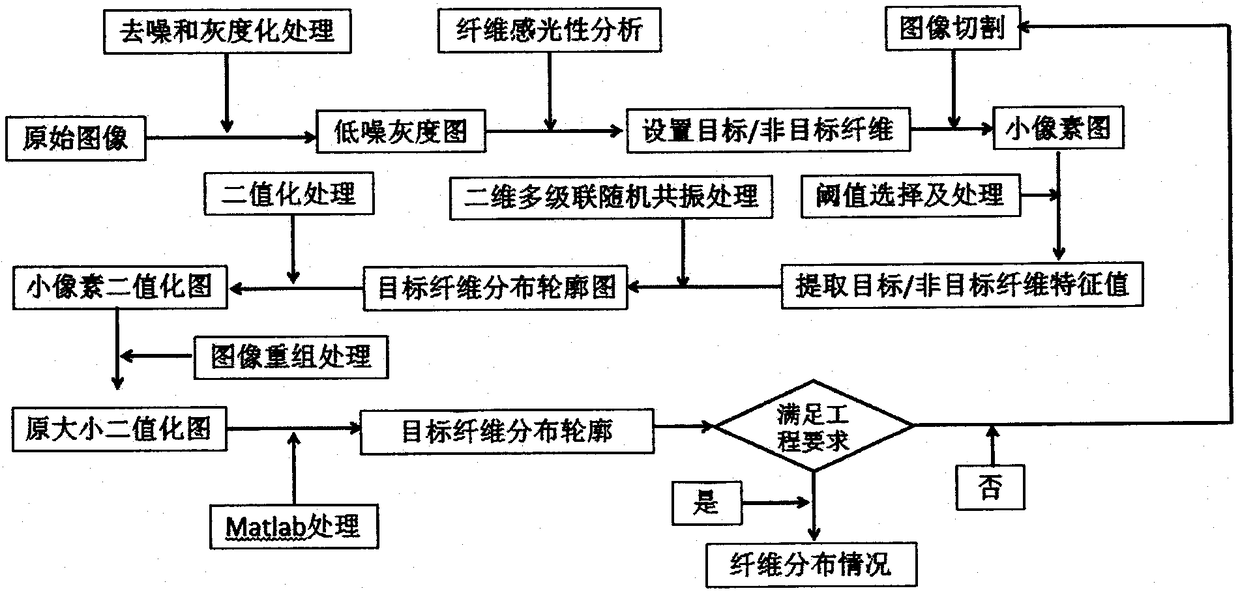

[0050] Image processing flow such as figure 1 As shown, the specific steps are as follows:

[0051] First, use the image collector to randomly collect the fiber web image made of the fourth group of mixed fiber ratios in Table 2, with a pixel size of 3000 pixels × 4000 pixels (such as Figure 13 shown), the collected image is denoised and grayscaled using Sobel filter method and weighted average method (such as Figure 14 shown).

[0052]Due to the difference in light sensitivity between glass fiber and polyester fiber, using this feature, Figure 13 The white part is basalt fiber, and the black part is polyester fiber. In this paper, basalt fiber is set as the target fiber and polyester fiber is set as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com