Method for improving thick metal layer LIFT OFF technology pattern abnormality

A thick metal and metal layer technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of reducing the thickness of photoresist, achieve the effect of improving crack phenomenon, improving electrical parameters, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0039] The present invention is not limited to the following embodiments, and each figure referred to in the following description is provided for understanding the content of the present invention, that is, the present invention is not limited to the structures illustrated in each figure.

[0040] A method for improving abnormal pattern of thick metal layer LIFT OFF process, comprising the steps of:

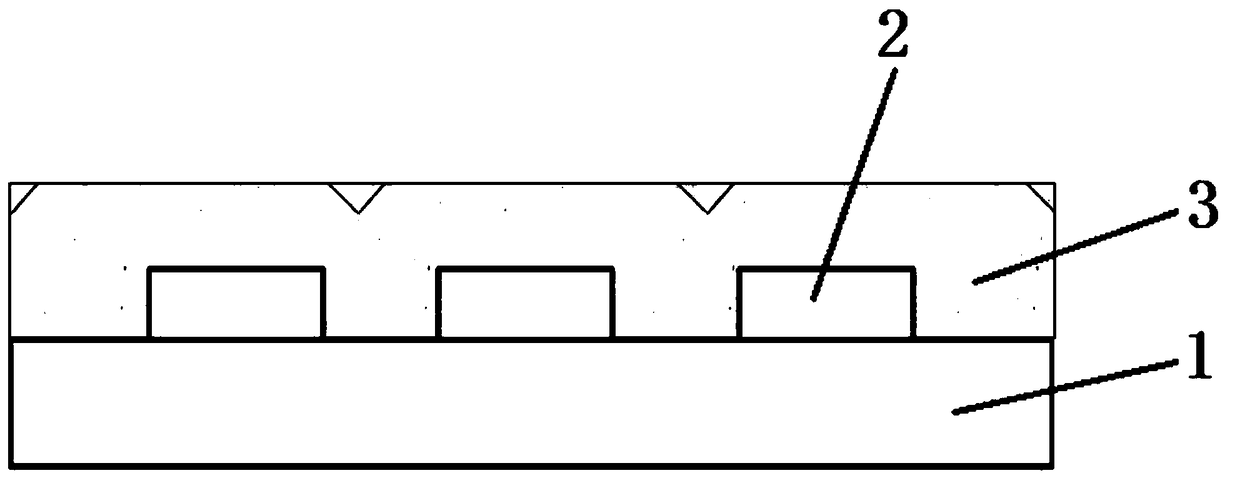

[0041] like figure 1 As shown, step 1. Photoresist coating: select a wafer substrate 1 patterned by a front-side process, coat photoresist 3 on the surface of the wafer substrate 1, and the thickness of the photoresist 3 is 6±0.5um;

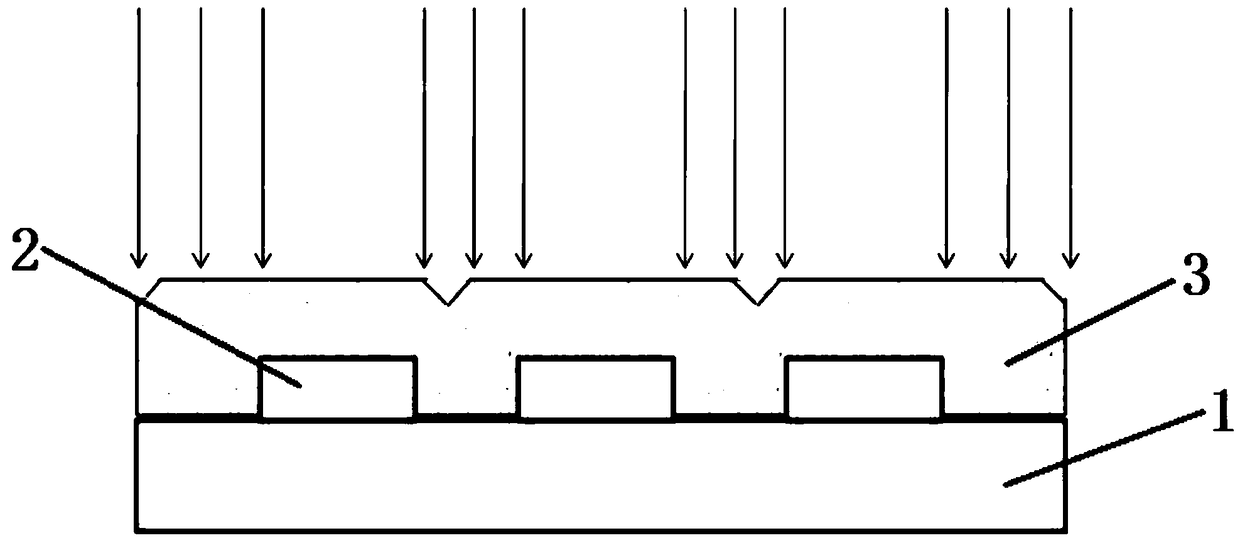

[0042] like figure 2 As shown, step 2. Photoresist exposure: under the shielding of the patterned photoresist plate, the photoresist 3 is exposed;

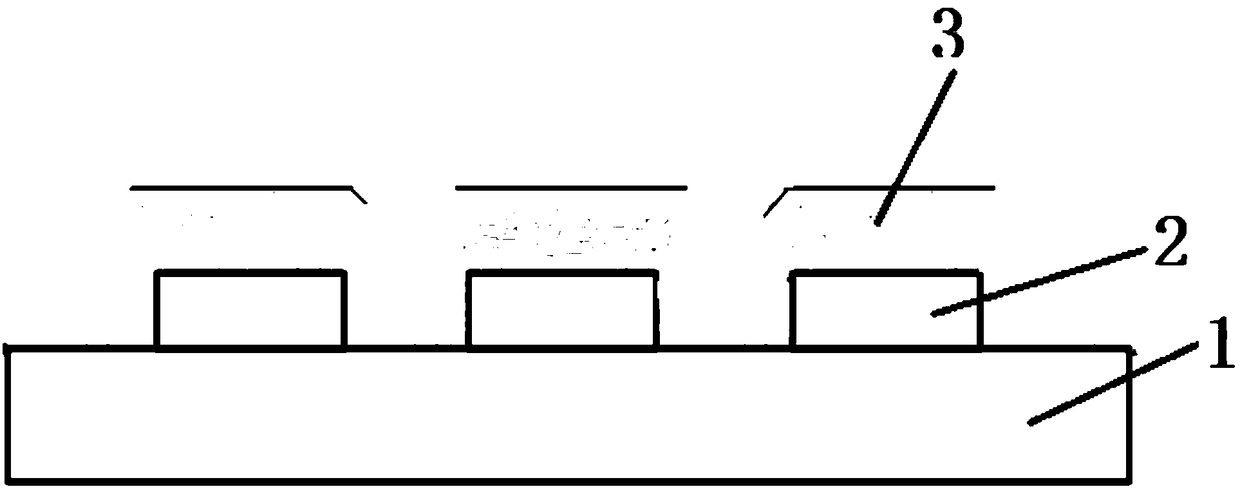

[0043] like image 3 As shown, step 3. Photoresist development: develop the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com