Making method of health-care food of coenzyme Q10 liposome

A liposome and coenzyme technology, applied in food science and other fields, can solve the problems of particle coagulation, low encapsulation efficiency, small particle size, etc., and achieve the effect of solving the problem of too small particle size and improving coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

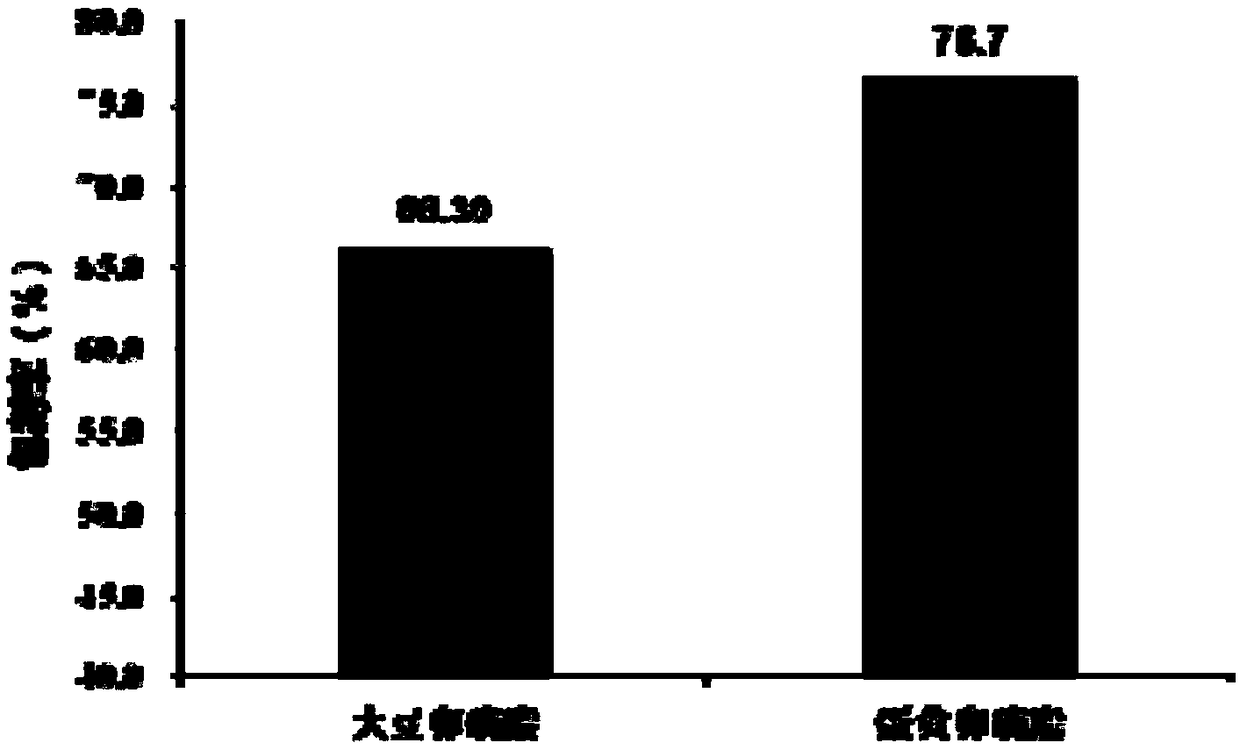

[0030] Coenzyme Q10 liposomes prepared from soybean lecithin with different phosphatidylcholine contents

[0031] 1 Experimental materials

[0032]

[0033] 2 Experimental methods

[0034] 1) Preparation of coenzyme Q10 liposomes

[0035] Dissolve 1.5g of soybean lecithin with different phosphatidylcholine content, 0.36g of cholesterol, 800mg of coenzyme Q10, 400mg of Tween-80 and 80mg of VE acetate in absolute ethanol, heat to dissolve at 60°C, and decompress in a water bath at 45°C Evaporate to form a smooth film, add 20mL of water phase medium PBS (pH=7.2) and 30-40 pieces of 4-5mm glass beads, hydrate the film in a water bath at 45°C to obtain an emulsified liquid, and ultrasonicate the emulsified liquid in an ice bath with an ultrasonic power of 400W, working time is 5min (working 1s / intermittent 1s), through ultrasonic emulsion to obtain coenzyme Q10 liposomes with a particle size of nanometer.

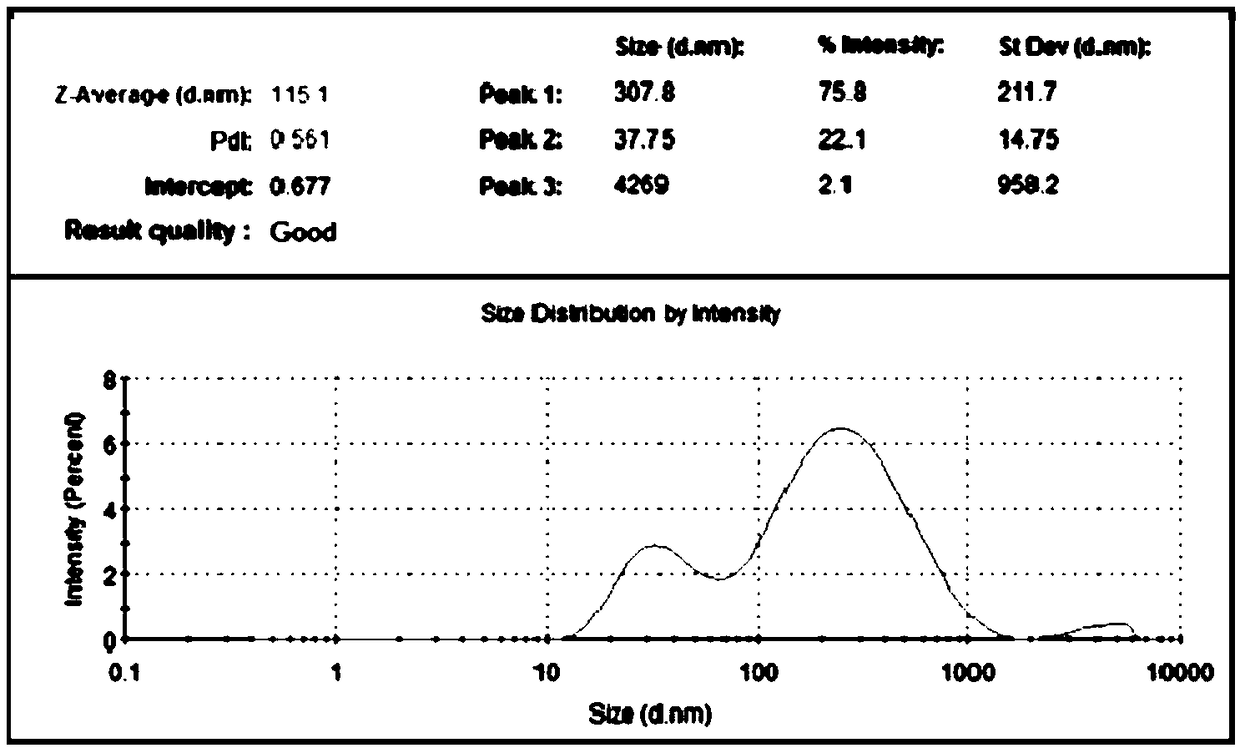

[0036] 2) Determination of particle size and polydispersity index PDI...

Embodiment 2

[0041] The coenzyme Q10 liposome prepared by embodiment 2 soybean lecithin

[0042] 1 Experimental materials

[0043]

[0044] 2 Experimental methods

[0045] 1) Preparation of coenzyme Q10 liposomes

[0046] Dissolve 1.5g of soybean lecithin (90% phosphatidylcholine content), 0.36g of cholesterol, 800mg of coenzyme Q10, 400mg of Tween-80 and 80mg of VE acetate in absolute ethanol, heat at 60°C to dissolve, and dissolve at 45°C Evaporate under reduced pressure in a water bath to form a smooth film, add 20mL of water phase medium PBS (pH=7.2) and 30-40 glass beads with a particle diameter of 4-5mm, hydrate the film in a water bath at 45°C to obtain an emulsified liquid, and place the emulsified liquid in an ice bath Ultrasound, the ultrasonic power is 400W, the working time is 5min (working 1s / intermittent 1s), and the coenzyme Q10 liposome with a particle size of nanometer is obtained through ultrasonic emulsion.

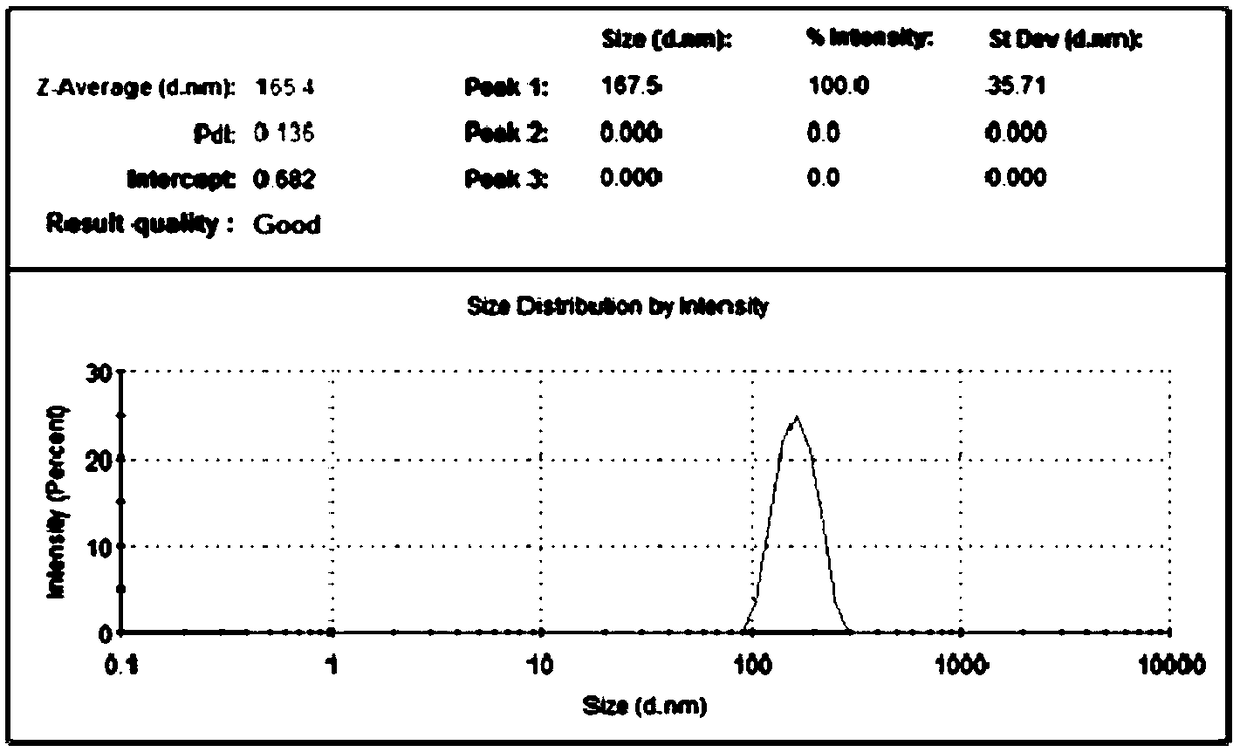

[0047] 2) Determination of particle size and polydispersit...

Embodiment 3

[0049] The coenzyme Q10 liposome prepared by embodiment 3 egg yolk lecithin

[0050] 1 Experimental materials

[0051]

[0052] 2 Experimental methods

[0053] 1) Preparation of coenzyme Q10 liposomes

[0054] Dissolve 3.0g egg yolk lecithin (phosphatidylcholine content is 60%), 0.72g cholesterol, 800mg coenzyme Q10, 500mg Tween-80 and 300mg VE acetate in absolute ethanol, heat to 60°C to dissolve, 45°C Evaporate in a water bath under reduced pressure to form a smooth film, dry in vacuum at 60°C for 2 hours, add 40mg of surfactant PVP and 3% protective agent glycerin, add 20mL of water phase medium PBS (pH=7.2) and an appropriate amount of 4-5mm glass beads, 45°C The emulsified liquid was obtained by hydrating the film in a water bath, and the emulsified liquid was subjected to ultrasonication in an ice bath, the ultrasonic power was 500W, and the working time was 5min (working 1s / interval 1s), and the nano-sized coenzyme Q10 liposomes were obtained through the ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com